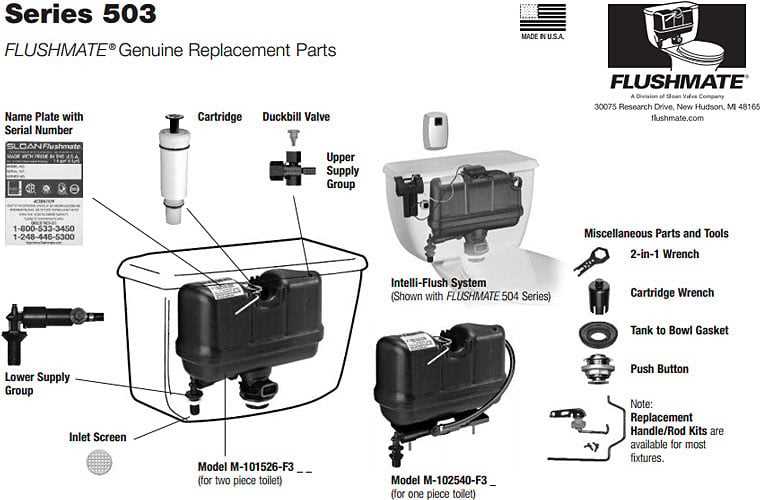

Proper understanding of the internal components of a toilet system is essential for efficient repairs and maintenance. Identifying each piece and its function can help address any issues that may arise, ensuring smooth operation. This section provides a visual breakdown of the crucial elements involved, making troubleshooting much simpler.

When dealing with plumbing issues, having a clear overview of the system’s design can save time and effort. Understanding the placement and role of each component allows you to pinpoint the problem more accurately. This guide focuses on highlighting essential parts and how they contribute to the proper functioning of your toilet system.

Familiarity with these components will also help you recognize when a part needs replacement or repair. Knowing the correct configuration will prevent common mistakes during installation and maintenance. By following a systematic approach, you can ensure the longevity of your toilet system and avoid costly repairs.

Understanding the Toilet System Components

Each element within a toilet’s flushing mechanism plays a critical role in ensuring efficient operation. These components work together to control the flow of water, create pressure, and ensure proper waste disposal. Gaining insight into how these elements interact helps prevent malfunctions and supports effective troubleshooting.

By recognizing the function of each part, users can quickly identify the source of common issues such as weak flushes or leakage. Whether dealing with a malfunctioning water valve or a clogged seal, understanding the internal structure of the system simplifies the process of identifying and resolving the problem.

To maintain a smoothly operating system, it’s essential to familiarize oneself with the roles and positioning of these components. A clear understanding of their relationships allows for accurate repairs and adjustments, leading to better performance and fewer disruptions in the long run.

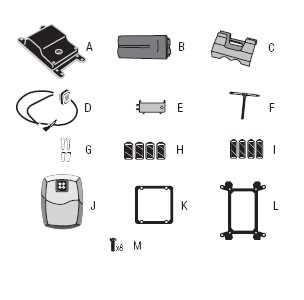

How to Identify Components in the System

Accurately identifying the individual elements within a toilet’s flushing mechanism is crucial for troubleshooting and repairs. A clear, well-labeled visual guide helps distinguish each part, making it easier to address specific issues. Knowing where each component fits into the system ensures that maintenance or replacement is performed correctly.

Step-by-Step Identification Process

Start by locating the main assembly and then work your way through the various components. Focus on understanding how each part interacts with others, such as the valve or pressure chamber, which are key to the system’s overall function. Pay attention to shapes and sizes to avoid confusion during installation or repair.

Tips for Efficient Identification

When reviewing a visual representation, look for any marked identifiers that correspond to the components you are inspecting. Familiarizing yourself with these details helps you quickly spot the parts you need to address. Remember, the more you practice identifying these components, the quicker and more accurately you’ll be able to perform maintenance tasks.

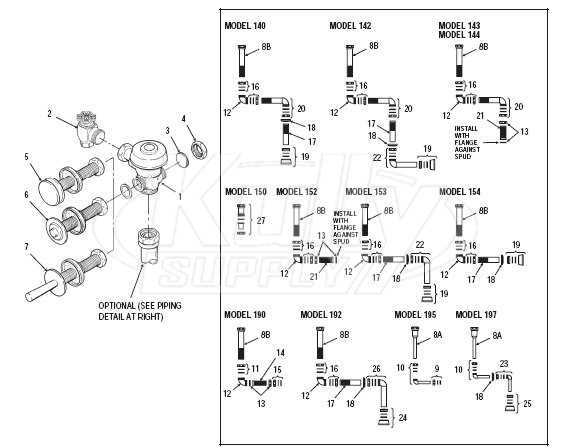

Troubleshooting Common Issues with Toilet System Components

When issues arise with a toilet’s flushing mechanism, understanding the typical problems that can occur with the internal components is essential. Common malfunctions often stem from a specific part or its interaction with others, leading to weak flushes, water leakage, or a failure to flush altogether. Identifying these issues quickly can save both time and money on repairs.

One of the most frequent problems involves poor water pressure. This can be caused by a clogged valve or a damaged seal. Another issue often seen is leakage, which may result from a worn-out gasket or improperly seated components. By recognizing these symptoms, you can target the problematic parts and make the necessary adjustments or replacements.

For persistent issues, ensure that all components are properly aligned and free of debris. Over time, certain elements may wear out and need replacement. Regular maintenance and understanding how each part functions together will help you resolve common problems and keep the system running smoothly.