Water management systems in commercial and residential buildings play a crucial role in maintaining efficiency and functionality. These systems rely on a variety of essential components that work together to ensure smooth operation. Whether you are looking to troubleshoot, replace, or maintain the system, understanding the key elements is vital for effective use and longevity.

One of the most important aspects of these systems is the network of valves, seals, and other integral parts that regulate water flow. Each part has a specific function, contributing to the overall mechanism’s performance. By gaining insight into the individual components and their interactions, you can better understand how to maintain or repair the system when necessary.

In the following sections, we will explore the main components involved in water control systems, focusing on their roles, assembly, and common issues. Knowing how these elements fit together will provide a solid foundation for anyone looking to work with or maintain these systems effectively.

Understanding Water Control System Components

Effective water management systems rely on a series of interconnected elements that regulate flow, pressure, and overall performance. These components are designed to work in unison, each serving a specific function to ensure the system operates smoothly. Understanding the roles of these key parts is essential for anyone involved in installation, maintenance, or troubleshooting.

Main Elements of the Water Control Mechanism

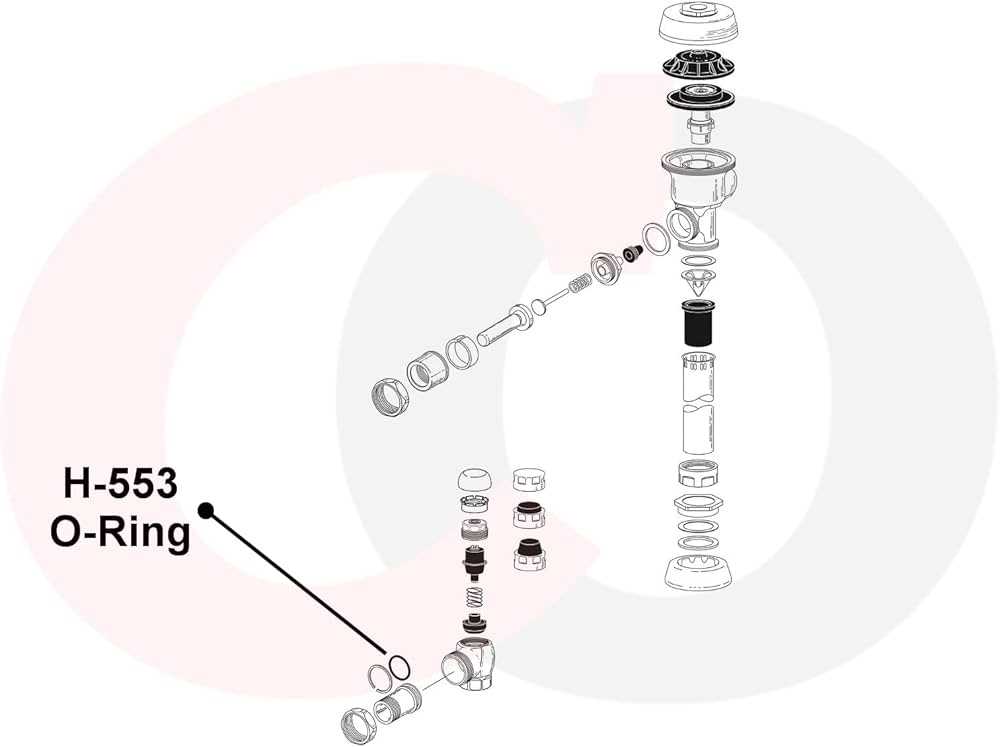

The core of any water regulation system typically includes valves, seals, diaphragms, and actuators. Each of these elements plays a critical role in managing the flow of water, ensuring that it is directed properly while maintaining necessary pressure levels. A malfunction in any of these components can lead to inefficiencies or system failures, making it crucial to have a good grasp of how they interact.

Assembly and Maintenance Considerations

Proper assembly and regular maintenance of these components are vital for the longevity and functionality of the system. Regular inspections of the internal parts, such as gaskets and diaphragms, are necessary to avoid wear and tear. Understanding how each part fits into the broader system allows for more effective repairs and replacements when necessary, ensuring continuous performance.

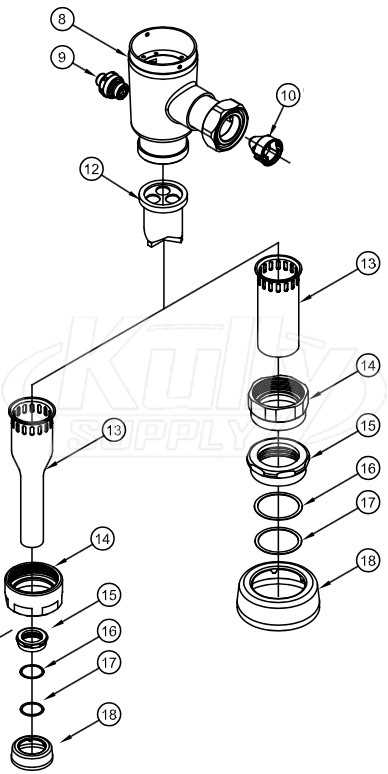

Key Parts in the Water Control System

The efficient functioning of a water regulation system depends on several crucial components that work together to control water flow and pressure. Each of these elements is designed to perform a specific function, ensuring the overall system operates as intended. A clear understanding of these components helps to manage, maintain, and troubleshoot the system effectively.

Among the primary elements are the valve mechanism, which regulates water release, and the diaphragm, which helps to control the system’s pressure and flow. Additionally, seals and gaskets play vital roles in preventing leaks and maintaining the integrity of the system. Proper knowledge of how each component interacts is key to understanding the system’s design and ensuring its efficient operation.

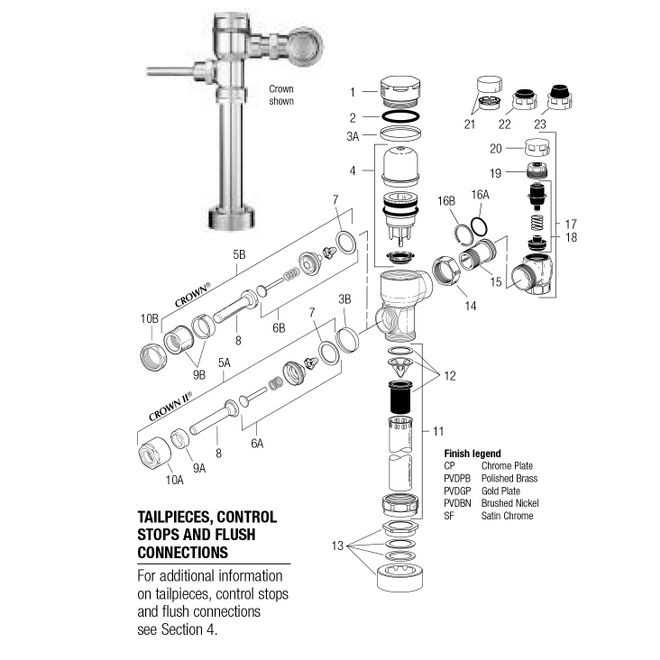

Step-by-Step Assembly of Water Control System

Assembling a water regulation system requires careful attention to detail and a solid understanding of each component’s role. Following a clear, step-by-step process ensures that the system is put together correctly, allowing it to function efficiently and reliably. Each phase of the assembly process is crucial to maintaining proper water flow and pressure management.

The first step in assembly is positioning the base unit and ensuring all seals and gaskets are correctly placed to prevent leaks. Next, attach the valve mechanism, making sure it is securely fastened and aligned properly. After this, the diaphragm should be installed, followed by any necessary adjustments to ensure that the system is calibrated for optimal performance. Finally, check all connections and test the system to confirm that everything is functioning as expected.