In any system that involves intricate fixtures and mechanisms, having a clear understanding of how each element fits together is crucial for proper functionality. This knowledge allows for smoother maintenance, efficient repairs, and a better grasp of how each part contributes to the overall performance.

Whether you’re troubleshooting a malfunction or planning an upgrade, referring to a detailed guide can help identify and address potential issues. It offers clarity on the placement and role of each component, ensuring that even complex systems can be easily understood and managed.

By gaining insight into the structure and relationships of key elements, users can enhance their experience, troubleshoot with precision, and extend the longevity of the system. Effective management of these details can make a significant difference in overall efficiency and durability.

Understanding the Components of Sloan Systems

Every mechanical system is made up of various elements that work together to ensure smooth operation. These individual components each play a critical role in maintaining the system’s functionality. Whether for installation, troubleshooting, or repair, understanding how each part fits into the larger structure is essential for achieving optimal performance and efficiency.

The Role of Individual Elements

Each element within a system serves a specific purpose, from regulating water flow to controlling pressure and ensuring safety. By familiarizing yourself with how these components interact, you gain a clearer understanding of the system’s overall mechanics. Focusing on each element allows for targeted adjustments and more precise interventions when issues arise.

Maintenance and Efficiency

Proper maintenance hinges on knowing what each component does and how it should function. Regular checks and replacements of essential parts can prevent major malfunctions and extend the life of the system. When repairs are needed, being familiar with the system’s core elements makes it easier to isolate the issue and apply a quick fix. Proactive care ensures consistent performance and reliability.

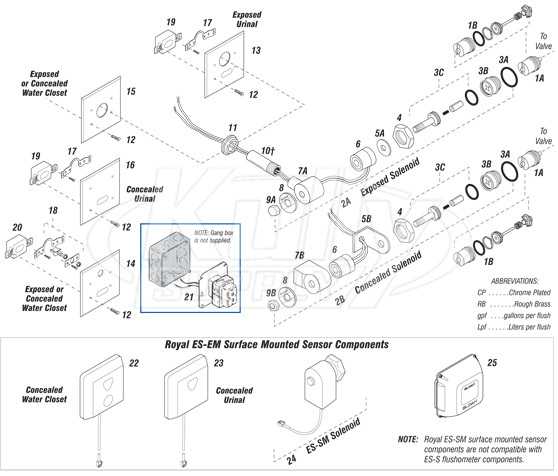

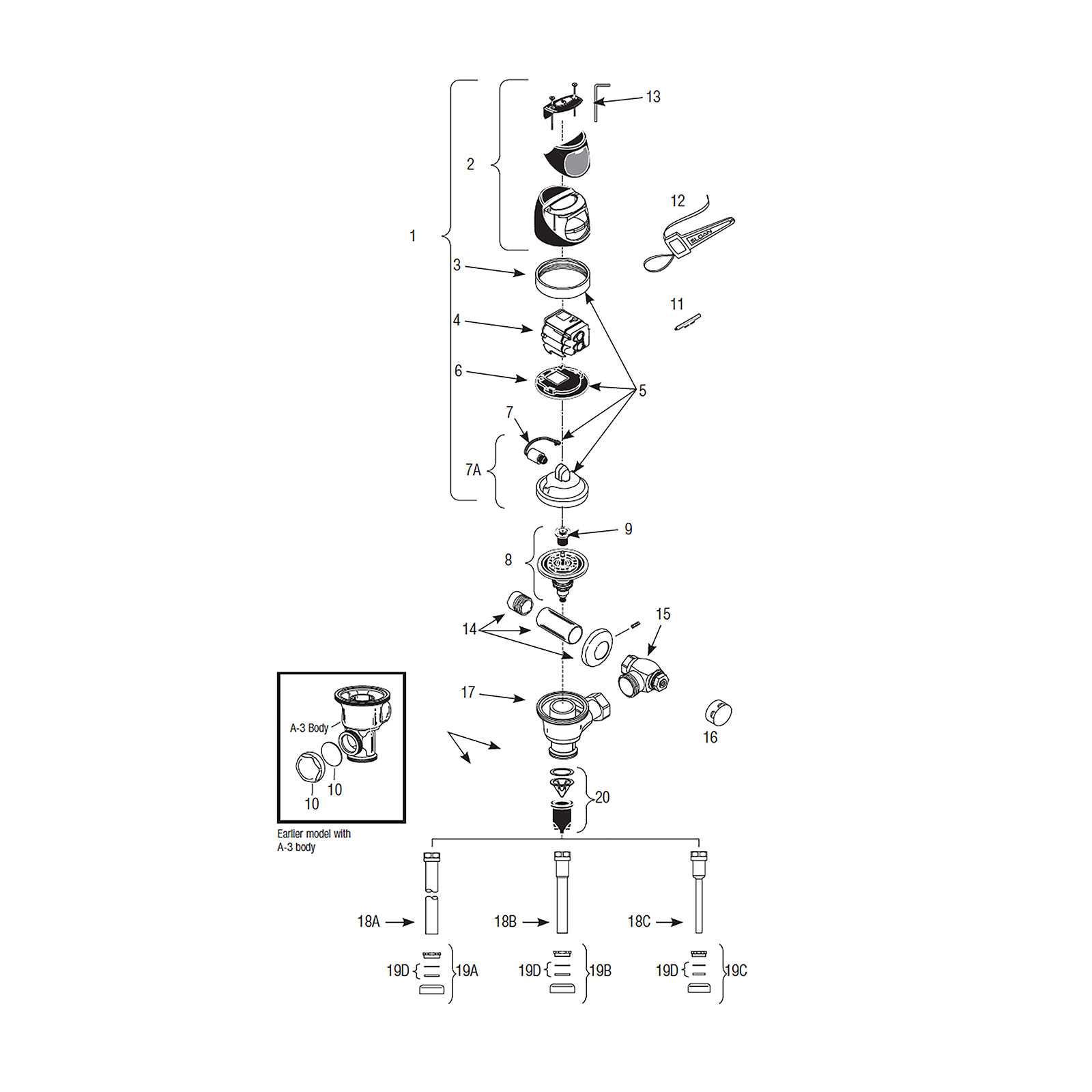

How to Read a Sloan Parts Diagram

Understanding technical schematics is essential for identifying and working with different components of a system. These visual representations provide a roadmap for assembling, repairing, or troubleshooting mechanical fixtures. By interpreting the symbols and layout, you can easily recognize the function and connection of each element within the system.

Identifying Key Symbols and Labels

Every schematic uses specific symbols to represent various components. Recognizing these symbols is the first step in accurately reading the visual guide. Labels provide additional context, helping to clarify the type and function of each element. Pay attention to both the size and placement of the symbols, as this can indicate how parts fit together or their sequence in the overall system.

Interpreting Connections and Flow

The connections between components often indicate how materials, such as water or air, flow through the system. By tracing these connections, you can understand how each element contributes to the system’s operation. Mapping the flow will also help in diagnosing potential issues, such as blockages or misalignments, that may hinder performance.

Common Issues and Solutions for Sloan Parts

Even well-designed systems can encounter problems over time due to wear, misuse, or environmental factors. Recognizing common malfunctions and knowing how to address them efficiently can prevent downtime and improve the overall longevity of the fixtures. With a clear understanding of the most frequent issues, you can implement quick fixes or determine when professional help is needed.

Water Flow Problems

One of the most common issues involves inconsistent or low water flow. This can occur due to clogged or damaged valves, blocked pipes, or faulty seals. Regular maintenance can help identify these issues early. Cleaning out debris, checking for leaks, and replacing worn components are often effective solutions to restore proper function.

Malfunctioning Sensors and Controls

Another frequent issue is malfunctioning sensors or control mechanisms. These can cause systems to be unresponsive or trigger false readings. Checking the wiring and recalibrating the sensors is often a simple solution. In more complex cases, replacing faulty sensors or control boards may be necessary to ensure accurate operation.