When it comes to maintaining your lawn mower, having a clear understanding of its key components is essential for optimal performance. Whether you’re performing routine maintenance or dealing with a malfunction, knowing how each part functions ensures the job is done efficiently and correctly.

Identifying and replacing malfunctioning components can prevent unnecessary damage and extend the life of your equipment. By familiarizing yourself with the essential elements of your machine, you can easily pinpoint issues and take the necessary steps to restore it to full working order.

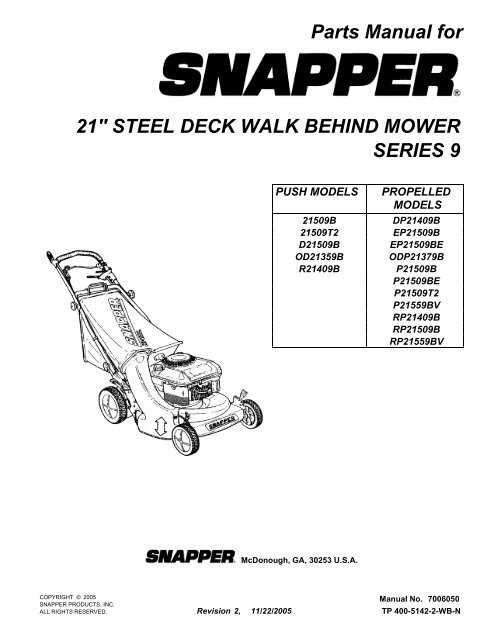

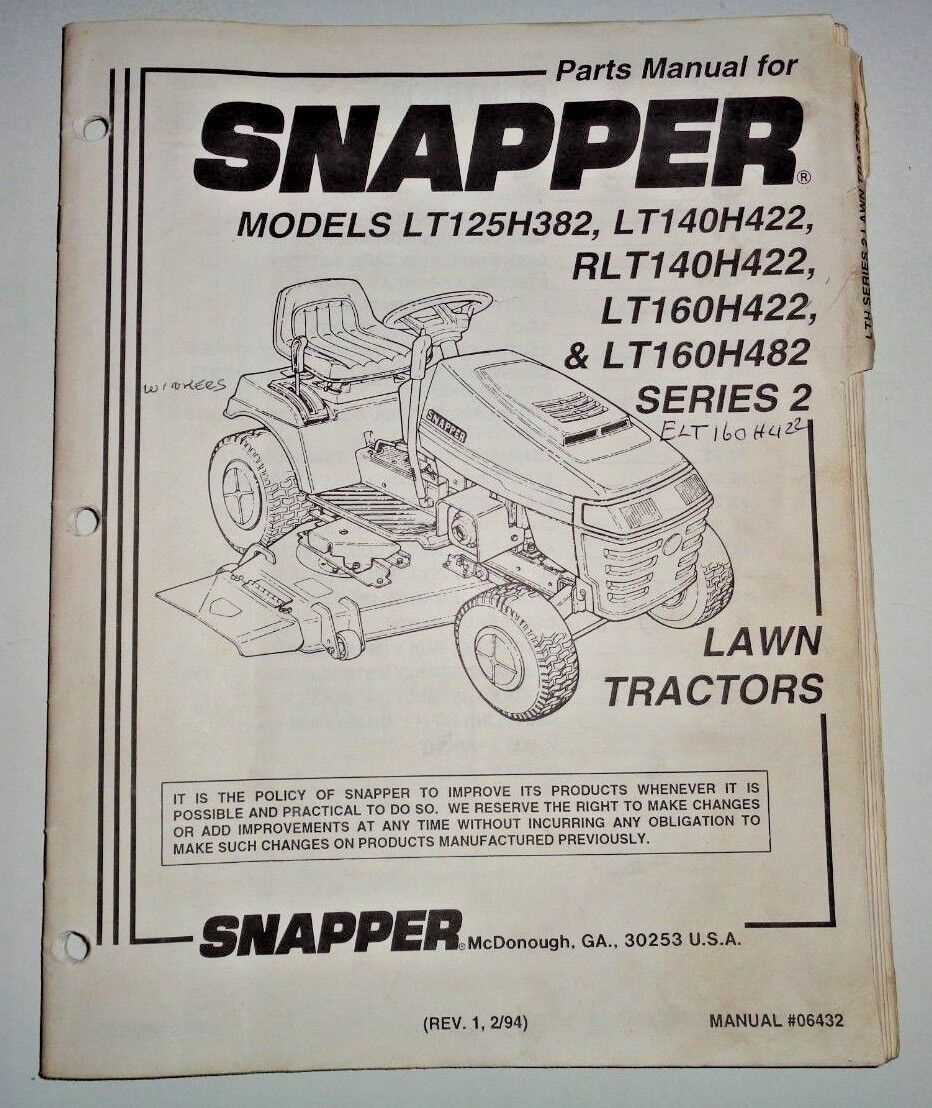

Proper care and timely repairs require access to an accurate visual guide of your mower’s internal structure. This comprehensive reference will help you understand the layout of various elements, making troubleshooting and repairs much simpler and more precise.

Understanding the Machine Layout

Having a clear overview of a lawn mower’s structure is crucial for any maintenance or repair tasks. A detailed visual guide helps users identify the various components and understand how they work together to ensure the smooth functioning of the entire system.

Each section of the guide presents specific parts of the equipment, providing valuable insights into their arrangement and function. Recognizing where each element fits into the larger picture makes diagnosing issues much simpler and aids in making informed decisions during repairs.

With a well-organized visual reference, you can easily navigate through the different sections and focus on the areas that require attention. This approach saves time and improves accuracy, ensuring that the equipment remains in optimal condition for longer periods.

How to Identify Machine Components

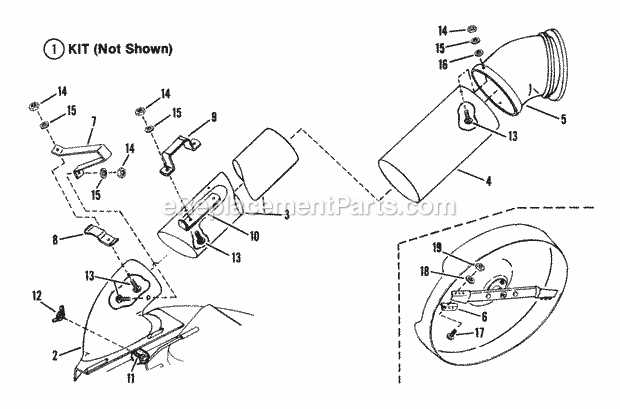

Identifying the individual components of your equipment is the first step in troubleshooting and maintenance. A clear understanding of each part’s function helps to locate issues and ensures efficient repairs. With the right approach, users can easily determine what needs to be replaced or fixed without unnecessary disassembly.

Step-by-Step Identification Process

Start by inspecting the machine from top to bottom. Begin with the visible elements, such as the engine, wheels, and handles. Then, check underneath and around for other critical components like belts, pulleys, and drive systems. This process helps you categorize the various sections, making it easier to diagnose problems as they arise.

Using Visual References

Utilizing a visual reference, like a schematic or image, can aid significantly in identifying and understanding the layout of the components. Such references offer a straightforward view, allowing you to pinpoint exactly where each part is located and how it integrates into the machine’s overall functioning.

| Component | Location | Function |

|---|---|---|

| Engine | Front section | Powers the entire machine |

| Wheels | Base | Provides movement and stability |

| Belts | Underside | Transmits power to other components |

| Handles | Top section | Allows for steering and control |

Step-by-Step Guide to Part Replacement

Replacing malfunctioning or worn-out components is essential for keeping your machine running smoothly. A structured approach ensures that each part is replaced correctly, preventing further damage and improving the overall functionality of the equipment. By following a systematic method, users can perform replacements efficiently and with minimal downtime.

Before starting, make sure to gather the necessary tools and have access to the replacement parts. It’s also essential to refer to a guide or manual to ensure the correct part is being replaced. Understanding the sequence of actions is critical to avoid confusion and ensure that everything is reassembled properly.

Preparation and Safety

Start by ensuring the machine is turned off and all power sources are disconnected. For safety, wear protective gloves and goggles. If necessary, elevate the equipment to access the areas where the components are located. Having a clean workspace will also help with organizing the tools and parts during the replacement process.

Step-by-Step Replacement Process

1. Identify the malfunctioning component and consult the guide for details on how to remove it.

2. Using the appropriate tools, carefully disconnect the faulty part from its connections.

3. Install the new component by aligning it properly and ensuring it fits securely in place.

4. Double-check all connections to ensure nothing is loose or improperly installed.

5. Test the machine to confirm that the replacement part functions as expected and the problem is resolved.

Ensure Proper Care for the Machine

Maintaining your equipment in optimal condition is essential for its longevity and performance. Regular care and attention to key components will prevent breakdowns, enhance efficiency, and reduce the need for frequent repairs. By incorporating simple maintenance practices into your routine, you can extend the lifespan of your machine and ensure it operates smoothly over time.

Routine Maintenance Tips

Start by cleaning the machine after each use to prevent dirt and debris from causing wear or clogging critical parts. Check fluid levels, including oil and fuel, to avoid running the engine dry. Additionally, inspect the blades or cutting elements regularly for any signs of damage or dullness, and sharpen or replace them as needed. Tighten loose fasteners to prevent vibrations and further damage.

Long-Term Care Strategies

For long-term care, store the equipment in a dry, sheltered area to protect it from weather damage. If the machine will be unused for extended periods, consider draining the fuel to prevent stagnation. Keep an eye on the condition of belts, pulleys, and other moving parts, as they may wear out over time and require periodic replacement.

Common Issues and Solutions for the Equipment

While regular maintenance helps keep the equipment in good condition, various problems may still arise over time. Recognizing common issues early on can save you time and money in repairs. By knowing the typical causes and solutions, you can address problems quickly and efficiently, ensuring your machine continues to perform at its best.

Frequent Problems

Several issues are commonly encountered with outdoor equipment. These problems can stem from wear and tear, improper maintenance, or environmental factors. Below are some typical problems and their solutions:

- Engine Fails to Start: This could be caused by a dead battery, faulty spark plug, or lack of fuel. Check the battery charge, clean or replace the spark plug, and ensure there’s enough fuel.

- Unusual Vibrations: Loose or damaged parts, such as the blades or belts, may cause vibrations. Inspect these components and tighten or replace them as necessary.

- Uneven Cutting: Dull or bent blades may result in an uneven cut. Sharpen or replace the blades and check for any damage to the cutting deck.

- Loss of Power: This could indicate an issue with the fuel system, air filter, or engine components. Check and replace the air filter and inspect the fuel system for any blockages.

Effective Solutions

Taking a proactive approach to maintenance can help avoid many of these problems. Regular inspections and addressing issues as soon as they arise can keep your machine running smoothly for years. Here’s how to deal with common concerns:

- Regular Cleaning: Keep the equipment clean to prevent dirt and debris from causing blockages or wear.

- Periodic Lubrication: Lubricate moving parts to reduce friction and prevent premature wear.

- Timely Part Replacement: Always replace worn or damaged components to prevent further damage to the equipment.