During the cold season, having reliable machinery to handle the accumulation of snow and ice becomes essential. To ensure smooth operation and longevity, it’s crucial to understand how different components work together in these machines. Proper maintenance begins with knowing each element and its function, allowing for quicker repairs and more efficient use.

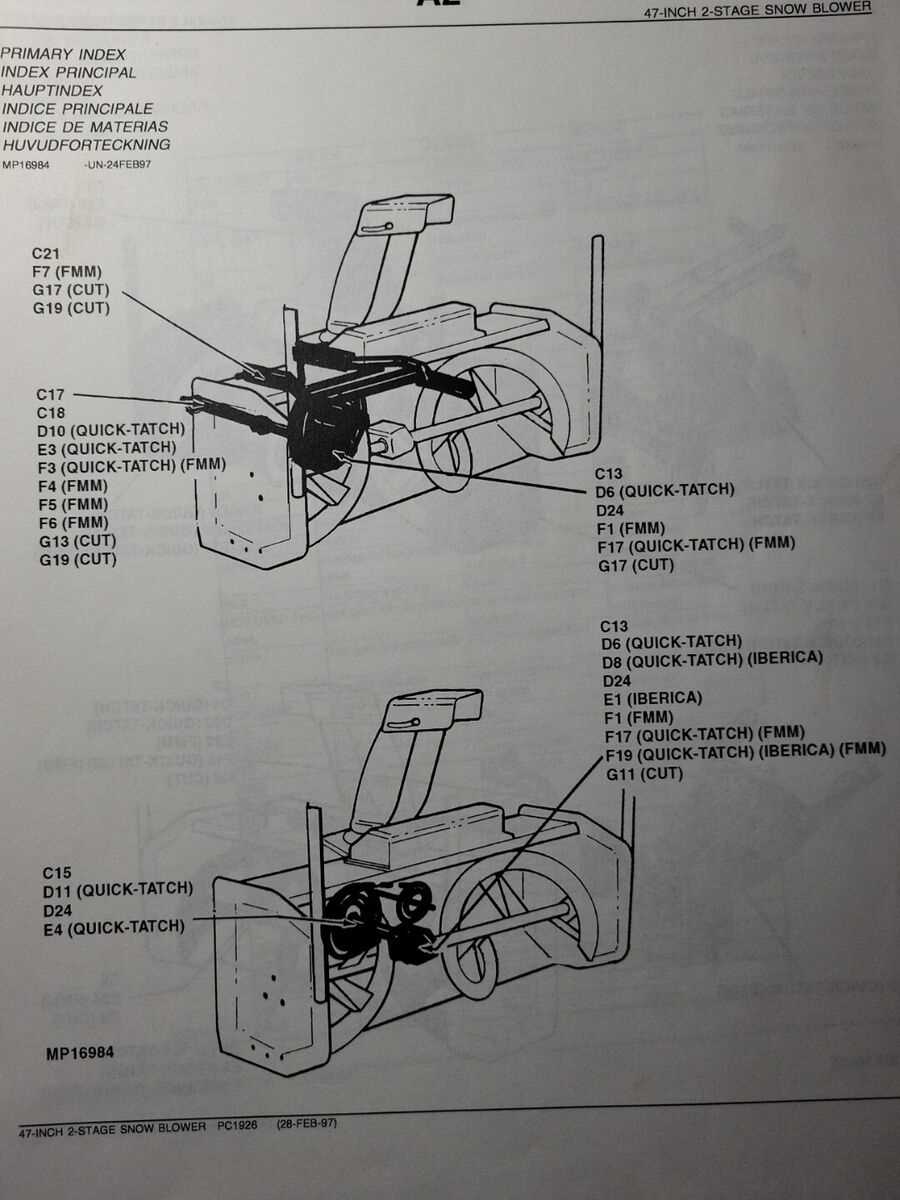

For any machine designed to tackle harsh winter conditions, recognizing the key components is the first step in preventing breakdowns. Detailed illustrations and clear identification of parts can greatly assist owners in both routine care and troubleshooting. Understanding the structure and mechanism of these devices helps identify wear and tear, ensuring timely replacements.

In this guide, we will explore how to navigate the internal and external components of winter equipment. By familiarizing yourself with the setup and assembly, you’ll be equipped to handle repairs effectively and maintain your machine’s peak performance.

Understanding Winter Equipment Components

To effectively maintain any machine used for clearing paths in winter, it’s essential to have a clear understanding of its internal and external elements. Knowing the role each component plays allows for better care and quicker troubleshooting. These devices consist of various mechanisms that work together to ensure efficient operation, and each part has a specific function that contributes to the overall performance.

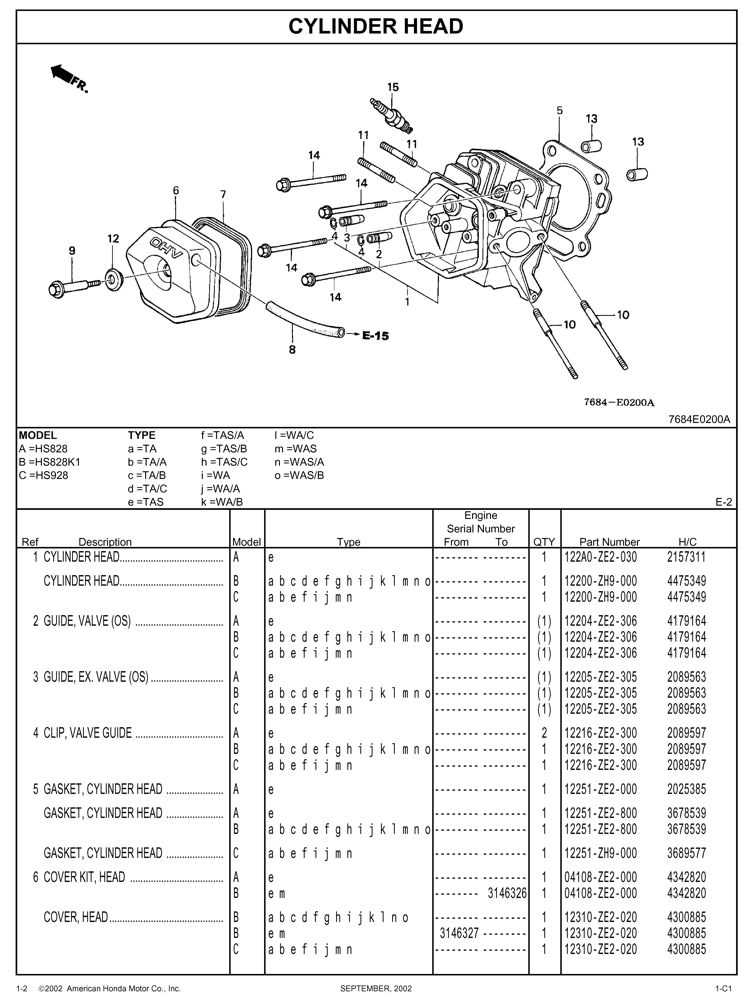

Key components include the engine, transmission, and various mechanical elements that help direct and expel material. Each plays a significant role in how well the machine performs in different conditions. Recognizing how these parts interact with each other enables users to detect potential issues before they become major problems. Understanding these relationships is the foundation for effective maintenance and repair.

By gaining a deeper knowledge of how the machine’s structure operates, users can ensure that all systems are functioning optimally. This understanding helps in identifying when parts need servicing or replacement, preventing costly repairs and downtime. Whether it’s routine upkeep or troubleshooting a malfunction, knowing how each piece fits into the whole system is crucial for effective maintenance.

How to Identify Key Winter Equipment Components

Understanding how to identify the main components of your winter equipment is essential for maintaining its performance. Knowing which part does what ensures that you can perform repairs and replacements when necessary. This process begins with recognizing the most critical elements that contribute to the machine’s operation. Once you are familiar with their functions, diagnosing issues becomes much easier, saving time and preventing unnecessary damage.

Step-by-Step Identification Process

To begin identifying the essential components, it’s helpful to follow a systematic approach. Here’s how you can do it:

- Start with the Engine: The engine is the heart of the machine. Recognize it by its size and positioning, typically at the front or rear of the unit.

- Transmission and Gearbox: Look for the system that drives movement. It’s usually a metal casing connected to the engine.

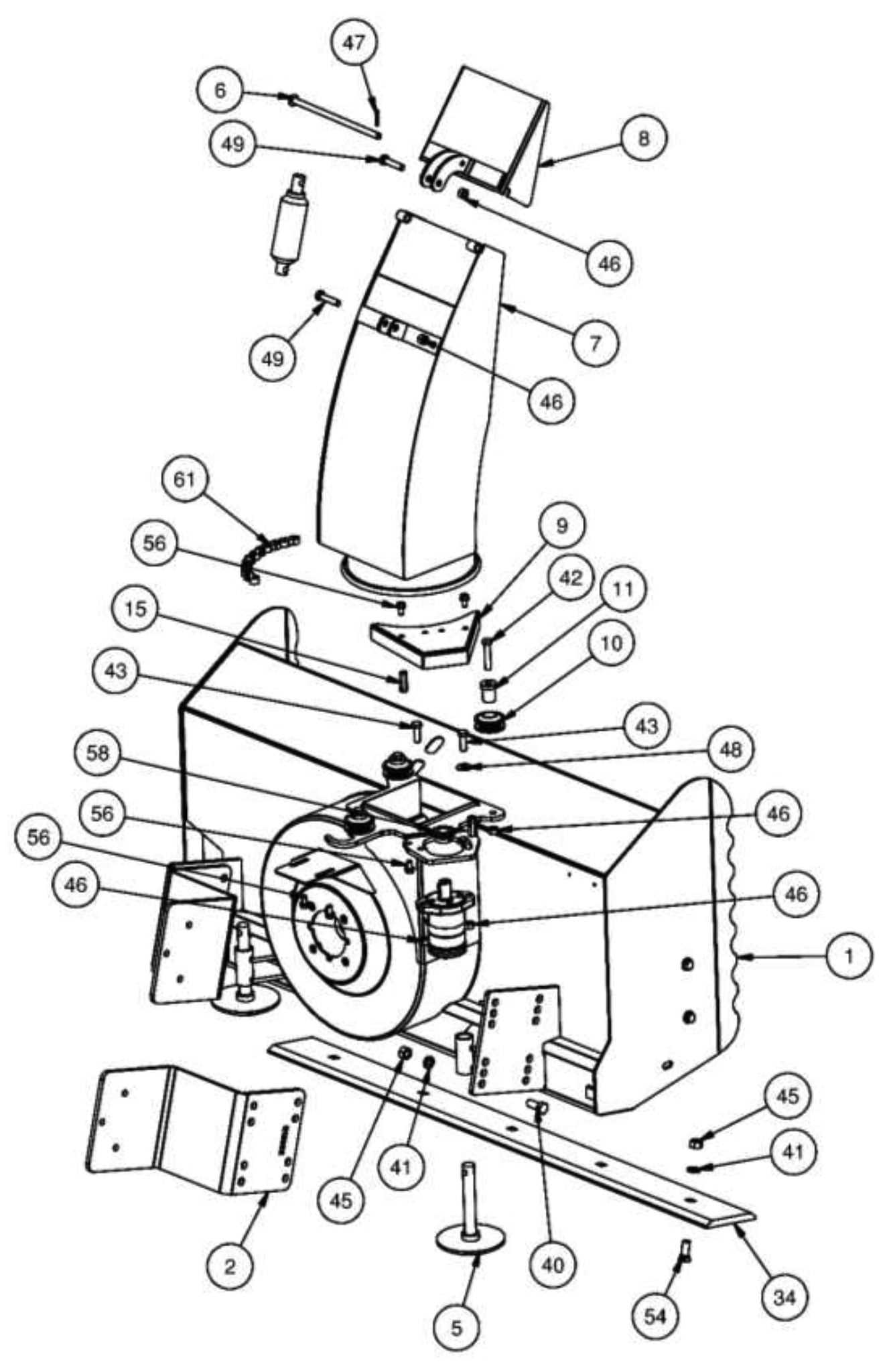

- Intake and Discharge Chute: These are usually located at the front and are responsible for directing the material.

- Auger Assembly: This is the part responsible for breaking up and gathering debris or snow. It’s a rotating component often made of metal or rubber.

Common Parts to Look for

Here are some of the most common components that you’ll need to identify and monitor for proper function:

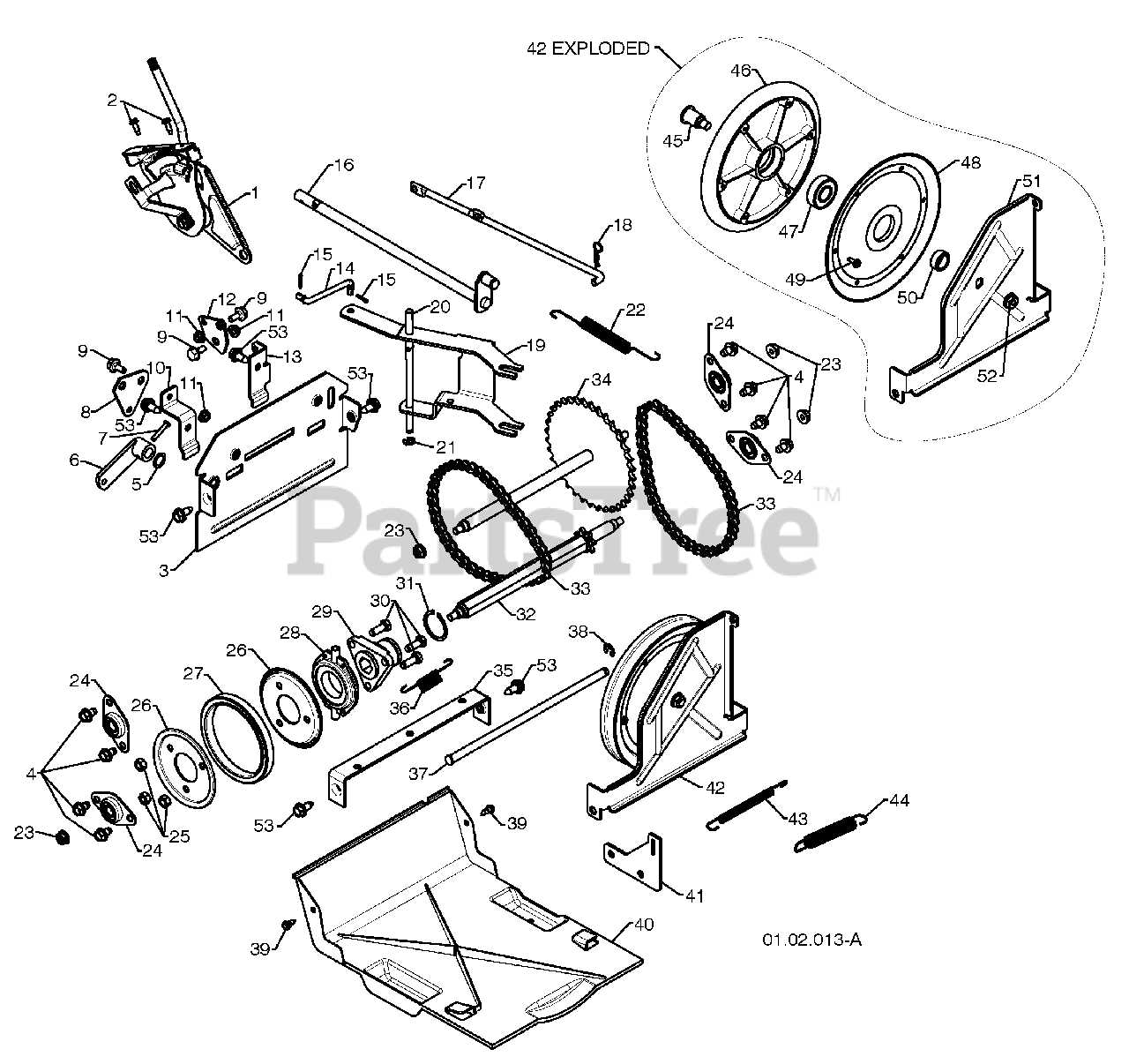

- Drive Belt: This component transfers power from the engine to other parts of the system.

- Wheels and Tracks: These provide mobility and should be checked for wear and tear.

- Fuel System: The fuel tank, lines, and filter all need regular inspection to avoid blockages or leaks.

- Controls: These include levers or buttons used to operate the machine, such as the throttle and speed settings.

Once you’ve familiarized yourself with these components, you’ll be able to perform quick inspections and pinpoint areas that may need attention.

Maintaining Your Winter Equipment with Component Illustrations

Effective maintenance relies on understanding how each part of your machine functions and how they all work together. Using visual guides that clearly depict the layout of various parts is a valuable resource for keeping the equipment in optimal condition. By regularly referencing these illustrations, you can perform detailed inspections, identify wear, and know exactly where attention is needed. This ensures that your machine operates at its best during the harshest conditions.

Steps to Maintain Your Equipment

To properly care for your machine, follow these steps using component illustrations:

- Regular Inspections: Refer to the visual guides to check each component for signs of damage or wear. This will help you spot potential issues before they cause more serious problems.

- Component Lubrication: Using the diagram, locate moving parts such as the auger and wheels. Ensure these are properly lubricated to prevent excessive wear.

- Cleaning and Debris Removal: Keep the areas around the intake, chute, and auger clear of any materials that might obstruct function. Refer to the illustrations to find hidden or hard-to-reach areas that need attention.

Using Illustrations for Quick Repairs

In the event of a malfunction, having access to detailed component visuals can make repairs quicker and easier. Instead of relying on memory or general knowledge, you can follow the diagram to pinpoint the exact location of the faulty component. This can significantly reduce downtime and the chances of errors during the repair process.

With a clear understanding of your machine’s layout and regular maintenance based on these visual guides, you’ll extend its lifespan and enhance its reliability when you need it the most.