When operating a snow removal system, it’s essential to understand the various components involved and their specific functions. Each element works in unison to ensure efficient operation and reliable performance in harsh winter conditions.

From the frame that supports the entire mechanism to the individual parts responsible for movement and power transfer, knowing how these elements interact is crucial for both repair and routine maintenance. Proper understanding also allows for better troubleshooting and ensures longevity of the equipment.

Maintaining these systems requires familiarity with their design and usage. Whether for a simple check-up or a more complex repair, understanding the layout and functions of each section can save time and effort. Knowing where each component fits and how it contributes to the overall function improves both safety and effectiveness.

Understanding Snow Way Plow Components

Efficient operation of snow-clearing machinery relies heavily on the precise arrangement and functionality of its individual elements. Each section is designed to serve a specific purpose, contributing to the system’s overall effectiveness in handling challenging winter conditions.

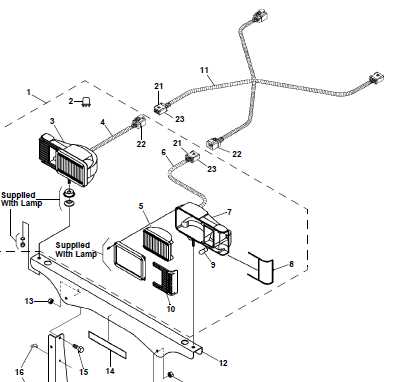

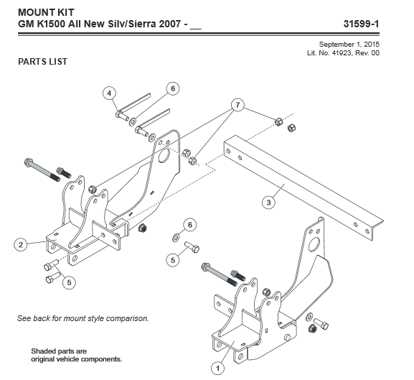

The core structure provides stability, while various moving parts ensure the mechanism can adjust and perform tasks such as lifting, angling, and pushing material. Other key components play crucial roles in delivering power and managing energy transfer throughout the system.

Understanding how each piece integrates into the broader system helps in both routine maintenance and troubleshooting. When all elements work together seamlessly, the machine can function reliably, even under heavy snow or extreme temperatures.

Key Parts and Their Functions

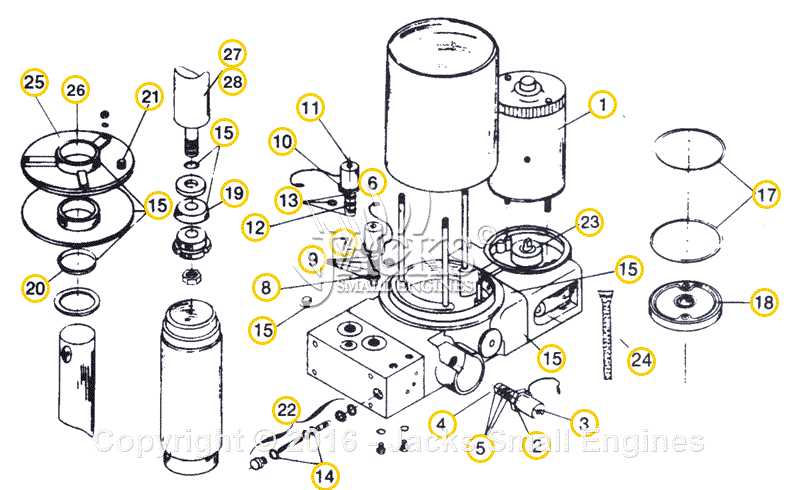

The effectiveness of a snow removal machine depends on the performance of its various key components. Each section plays a vital role in ensuring smooth operation, from providing movement to managing power distribution.

Frame: The frame acts as the backbone of the entire system, supporting all other elements and maintaining structural integrity during operation. It is crucial for distributing force evenly to prevent undue stress on individual components.

Lift Mechanism: This system is responsible for raising and lowering the working components. It allows the operator to adjust the angle for different conditions, such as deep snow or icy surfaces.

Drive System: This part transfers power from the engine to the working elements, enabling motion and control over the machine’s movements. It ensures consistent traction and efficiency when clearing large areas.

Angle Mechanism: This feature controls the direction of the material being cleared. By adjusting the angle, the operator can manage the path of the snow or debris, directing it where necessary.

Understanding the functions of these critical components ensures that maintenance, troubleshooting, and repairs are done effectively, preserving the system’s longevity and functionality. Proper care of each element guarantees a smoother and more efficient operation in harsh conditions.

How to Maintain Snow Way Plow Parts

Proper maintenance of a snow-clearing system is essential to ensure its longevity and optimal performance during winter months. Regular care and inspection of the machinery’s components can prevent costly repairs and ensure that each element functions as intended.

The first step in maintaining these systems is to regularly inspect key components for wear and tear. Lubrication is crucial for moving parts to ensure smooth operation and reduce friction. Keeping the frame clean and free from debris also helps prevent rust and damage caused by moisture buildup.

Checking and replacing fluid levels, such as hydraulic oil, is another important task to maintain proper functionality. Ensure that all seals and connections are secure to avoid leaks that could hinder performance. Additionally, the lift mechanism and angle controls should be tested regularly to ensure they are responsive and operate without obstruction.

Lastly, after each use, ensure the system is thoroughly cleaned to remove any built-up snow or ice, preventing it from freezing and affecting future performance. Routine checks and consistent care will help preserve the equipment, allowing it to perform reliably for many winters to come.