Maintaining outdoor machinery during the cold season requires a clear understanding of its key elements. Whether you’re a professional or a hobbyist, knowing how the various components fit together and function is essential for smooth operations. A well-maintained system ensures efficient performance and minimizes downtime during harsh weather conditions.

Proper maintenance can extend the lifespan of your equipment, reduce costly repairs, and improve its overall efficiency. Understanding the role of each individual piece allows for quicker troubleshooting and more effective use of your tools. From motors to hoppers, every element plays a critical role in the overall functioning.

By exploring the layout and design of your machinery, you can make informed decisions about repairs, upgrades, and regular upkeep. A detailed guide to the system’s components offers invaluable insights that help ensure reliable performance throughout the winter season.

Understanding Snowex Salt Spreader Components

Each piece of machinery designed for winter operations is made up of a variety of integral components that work together to achieve optimal performance. From the primary drive systems to the smaller accessories, every element has a specific function that supports the overall process. Grasping how each component interacts within the system is key to efficient use and troubleshooting.

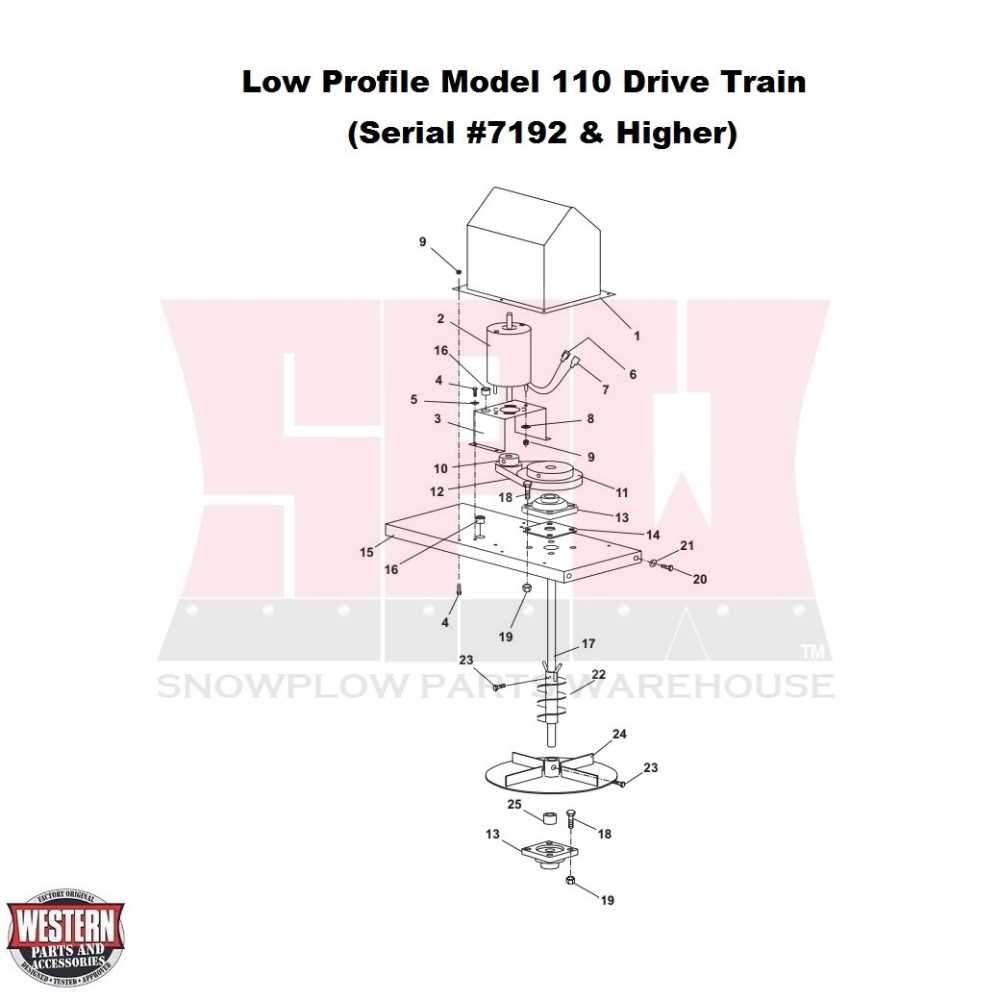

Mechanical systems such as the motor, auger, and gearbox are vital for movement and control. These work in unison to regulate the flow of material and direct it to the designated area. Understanding their placement and function helps to avoid operational issues and ensures smoother adjustments when needed.

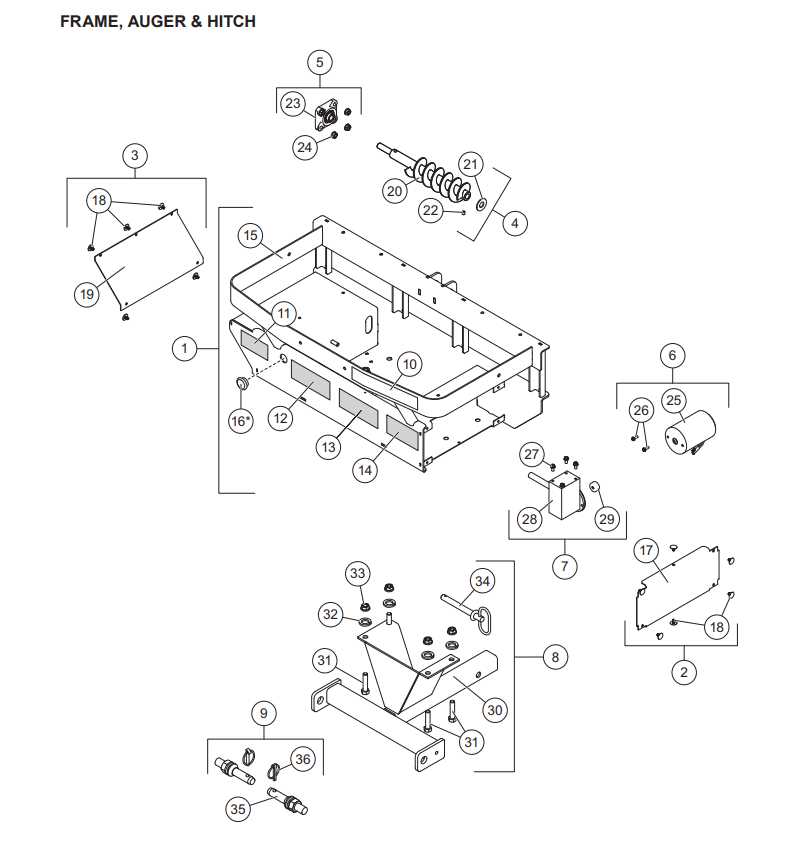

Additionally, structural elements like the frame and hopper support the system’s stability and the proper distribution of materials. Their design determines how well the equipment can handle weight, volume, and rough handling conditions during use. Familiarity with these components aids in identifying potential wear and tear, which can help prevent failures during critical moments.

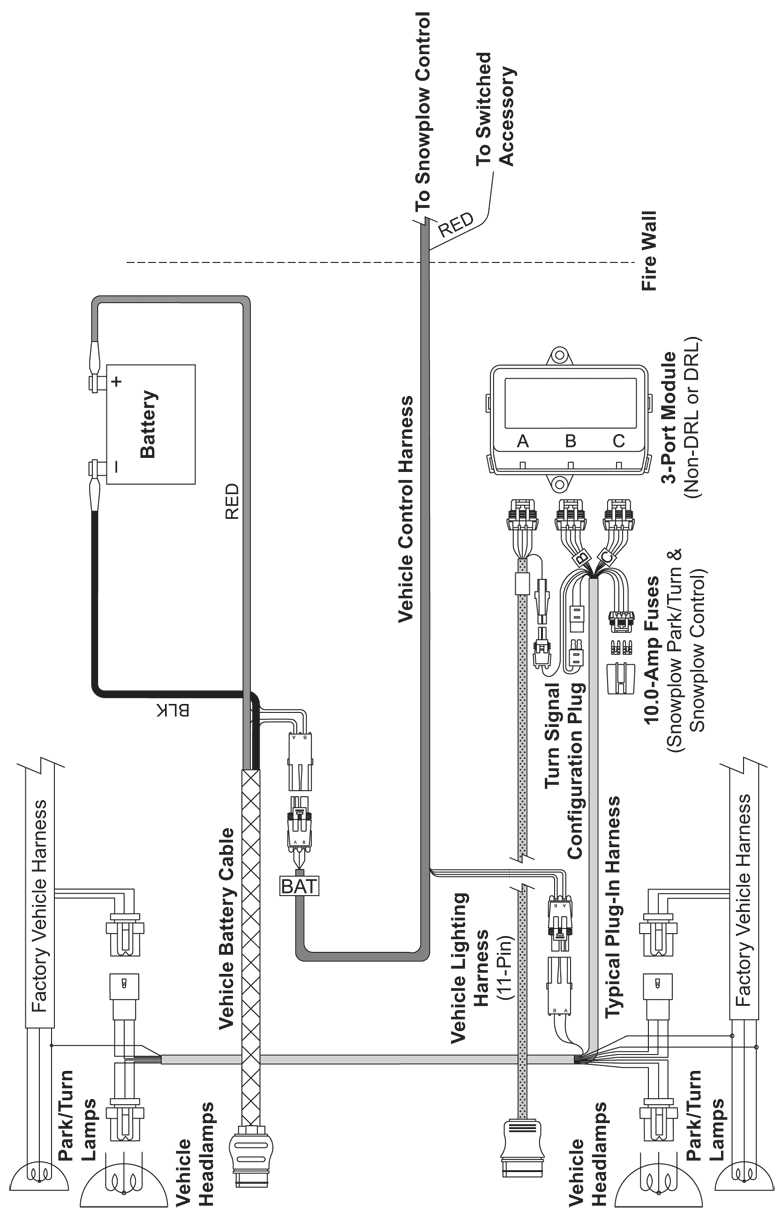

Lastly, electrical and control systems ensure that the user can easily operate the equipment, offering a range of functions from speed control to material flow management. These systems need to be maintained regularly for reliable performance, as they are often the first to malfunction due to exposure to elements or wear from frequent use.

How to Read the Snowex Parts Diagram

Understanding the layout of your equipment and its various components can be crucial for effective maintenance and troubleshooting. A well-structured visual guide helps users identify the specific parts, their functions, and how they interact within the system. Learning to read this schematic properly allows for faster identification of issues and simplifies the process of repairs.

Identifying Key Components

The first step in reading the schematic is to familiarize yourself with the key components represented. The diagram typically uses standardized symbols to denote different mechanical and electrical elements. For instance, motors, gears, and control mechanisms are often marked with distinctive symbols to make identification easy. Paying attention to these markings ensures that you can locate the part you need to inspect or replace quickly.

Understanding the Connections

Once you’ve identified the individual parts, the next step is understanding how they are connected. Lines and arrows in the schematic often represent cables, hoses, or mechanical linkages that transmit power or material. Understanding these connections is critical for diagnosing issues such as poor performance or system failure, as it allows you to follow the flow of energy or material through the system.

Common Snowex Salt Spreader Repairs

Over time, outdoor machinery used for winter operations may experience wear and tear, requiring routine repairs to keep everything functioning smoothly. Recognizing the common issues that arise with these systems and knowing how to address them is essential for extending their lifespan and preventing larger, costlier breakdowns. Many problems can be resolved with a basic understanding of the system’s structure and functionality.

Motor and Gearbox Troubleshooting

One of the most common issues involves the motor and gearbox, which can become worn down after prolonged use. In many cases, malfunctioning motors result from electrical failures or worn-out brushes. The gearbox, responsible for transferring power to various components, may also encounter issues like stripped gears or poor lubrication. Regular inspections and timely replacement of these components help maintain the overall performance of the machine.

Material Flow and Distribution Problems

Another frequent issue is uneven material flow or distribution. This can occur when the auger or hopper system becomes clogged or damaged. In some cases, debris may obstruct the flow path, leading to inefficient operation. Addressing this involves clearing blockages and checking for any worn-out seals or malfunctioning mechanisms. Ensuring proper calibration of the control system also plays a significant role in preventing material distribution issues.