Proper knowledge of your gardening equipment’s components is crucial for optimal performance. Understanding how each piece fits together and functions can significantly improve maintenance and extend its lifespan. Regular inspections and timely replacements are key to preventing malfunction and ensuring efficient use.

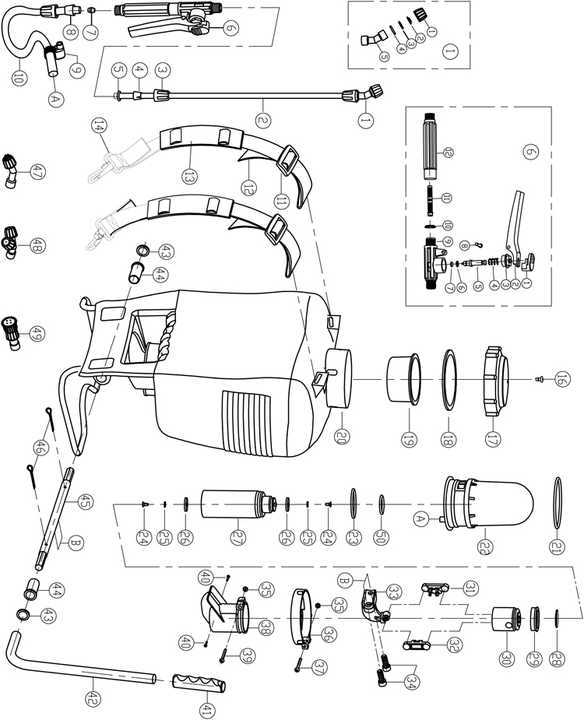

In this section, we will explore the individual elements that make up a commonly used spraying device. By breaking down the structure and explaining the role of each component, you can gain a deeper understanding of how to handle repairs and replacements more effectively.

Comprehending these details will not only enhance your usage experience but also enable you to tackle any issues with confidence, ensuring your device remains in peak condition throughout its service life.

Understanding the Solo Backpack Sprayer

Efficient gardening equipment is essential for tasks such as pesticide or fertilizer application. Devices designed for spraying liquids are commonly used to cover large areas quickly and uniformly. These machines are equipped with several essential components, each contributing to their smooth operation and performance.

Key Features of the Device

The equipment’s central tank holds the liquid solution, which is then distributed through a nozzle by a pressurized system. Understanding the flow of liquid from the reservoir to the nozzle can help users monitor the performance and troubleshoot any issues that may arise. Each part of the system is connected and designed for durability, ensuring a long lifespan when properly maintained.

Efficient Functionality and Maintenance

Regular inspection of the pressure mechanism and valves ensures optimal functionality. By identifying wear or damage early, users can replace worn-out parts, preventing costly repairs. Cleaning the device after each use is also crucial to maintaining its efficiency, keeping it ready for future tasks.

Essential Components of Solo Sprayers

To ensure optimal performance, it’s important to understand the key components that make up a liquid distribution device. These elements work together to create a reliable system that delivers uniform coverage for various tasks, from gardening to pest control.

Core Elements of the System

The tank serves as the primary reservoir for the liquid, while the pump is responsible for building up pressure to propel the fluid through the system. A well-functioning pump ensures the right flow and pressure for effective spraying. Additionally, the hose and nozzle are crucial in directing the liquid to the intended surface, providing precision in application.

Supporting Features for Smooth Operation

Other features like the trigger valve and filters are essential for controlling the liquid release and preventing blockages. Regular maintenance of these components ensures long-term functionality and prevents downtime caused by wear or clogging. Ensuring all parts are in good working condition will maintain the device’s efficiency and durability.

How to Maintain Your Solo Sprayer

Proper maintenance is crucial for ensuring the longevity and efficiency of your liquid application device. Regular care and attention to key components can prevent unexpected failures, reduce repair costs, and enhance overall performance. By following a few simple steps, you can keep your equipment in top condition for years of reliable use.

Routine Inspections and Cleaning

After each use, it is important to thoroughly clean the tank, hose, and nozzle to prevent residue build-up and blockages. Use clean water and a mild detergent to flush the system, ensuring that no chemicals remain that could damage components over time. Regular cleaning helps maintain fluid flow and prevents clogging.

Checking and Replacing Wearable Parts

Some components, such as filters, valves, and gaskets, may experience wear and tear over time. It is essential to inspect these parts periodically for any signs of damage or degradation. Replacing worn-out components quickly can prevent further damage and maintain the pressure system’s efficiency, ensuring a smooth and reliable spraying experience.