When using tools designed for applying coatings, understanding the individual elements that make up these devices is crucial. Each element plays a specific role in ensuring smooth operation and optimal results. Proper knowledge of how each part functions together can significantly enhance the overall experience and efficiency during use.

Recognizing the structure of the device allows users to troubleshoot issues and perform maintenance, ensuring longevity and effective use. From the housing to the nozzles, each component interacts with others to create a seamless application process.

By familiarizing yourself with these components, you can improve not only the performance but also the safety and quality of your work. Knowing the correct way to handle and maintain each part is essential for achieving consistent and professional results in various projects.

Key Components of a Painting Tool

Every tool designed for applying coatings consists of several key elements that contribute to its overall function. Understanding these essential components helps users operate the device effectively, ensuring a consistent and high-quality finish in various applications. These components, when properly maintained, work together to provide a seamless experience.

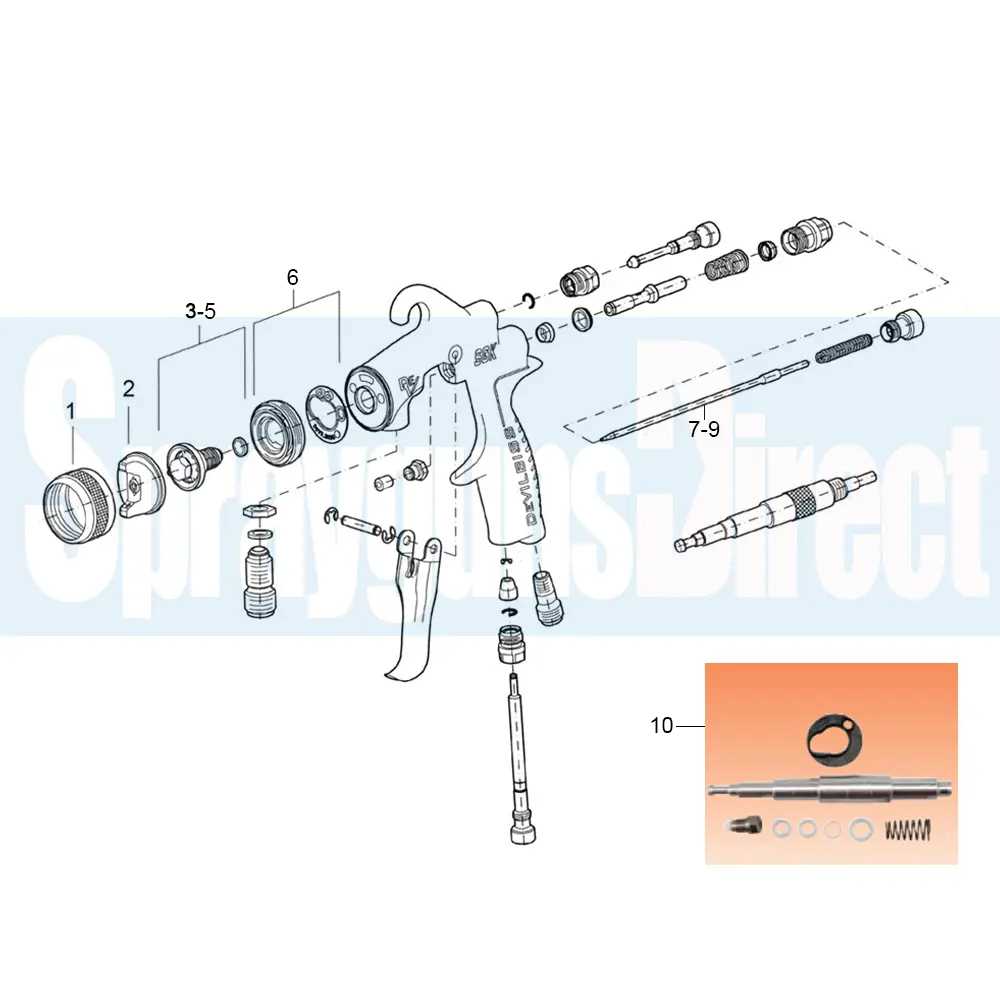

Housing and Trigger Mechanism

The housing is the central structure that holds all other elements in place. It provides stability and durability during use. The trigger mechanism, located on the housing, controls the flow of material, allowing the user to start and stop the application process with ease. A responsive and well-maintained trigger is critical for precise control over the material’s release.

Nozzle and Air Cap

The nozzle is the component through which the material exits the tool, and it plays a crucial role in determining the spray pattern and flow rate. Paired with the air cap, it helps direct the airflow to ensure an even and controlled application. Proper maintenance of both the nozzle and air cap ensures that the spray remains consistent and free of clogs.

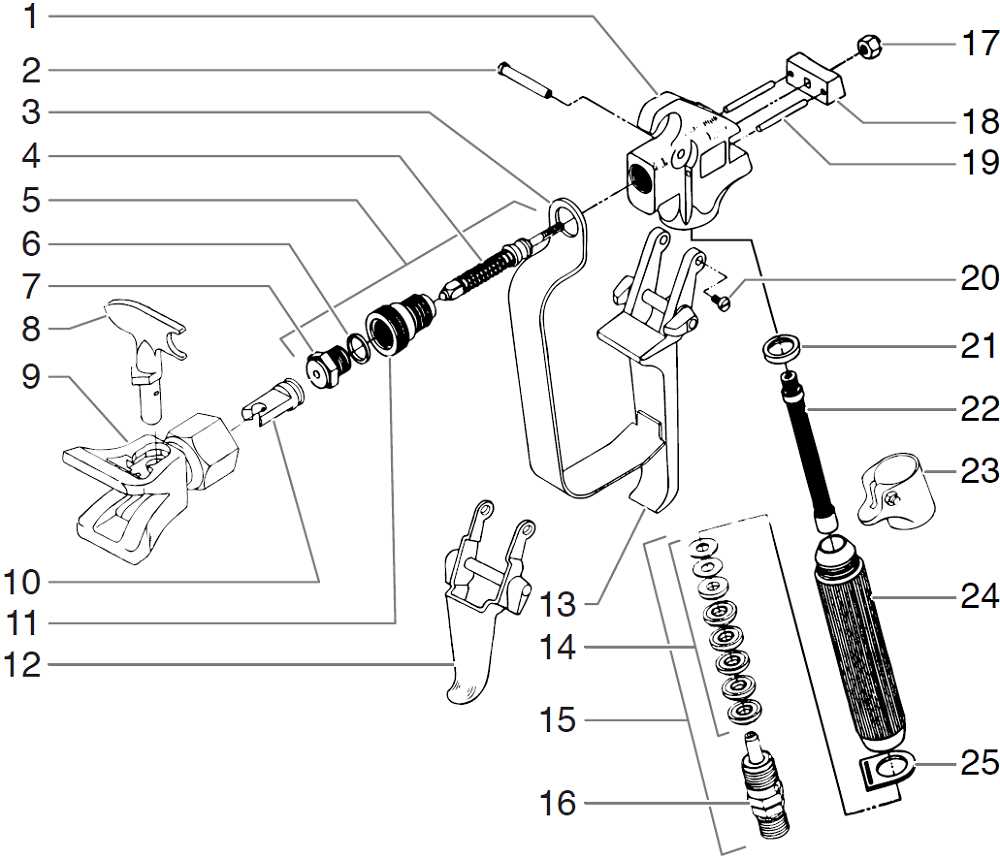

How to Identify Spray Tool Components

Recognizing the individual elements of a coating application device is essential for troubleshooting and proper usage. Each component has its distinct role, and understanding their specific function ensures that users can identify issues and perform necessary repairs or maintenance with ease. Knowing what each part does helps in the smooth operation of the tool, contributing to better results in the application process.

Begin by examining the housing, as it serves as the base structure. This component holds everything together and provides the framework for all other parts. The handle, often attached to the housing, offers a secure grip, making the tool easier to control during use.

Next, focus on the nozzle and air cap, which are key for the application process. The nozzle controls the flow of the material, while the air cap directs the airflow, ensuring even distribution. Pay attention to the shape and size of these components to determine their specific functions.

Maintaining Your Tool for Efficiency

Proper maintenance of your coating application tool is essential for ensuring long-lasting performance and efficient operation. Regular care and attention to detail will help prevent malfunctions and ensure that the device delivers optimal results. By keeping the components clean and in good working condition, you can extend the life of your tool and maintain high-quality results in every project.

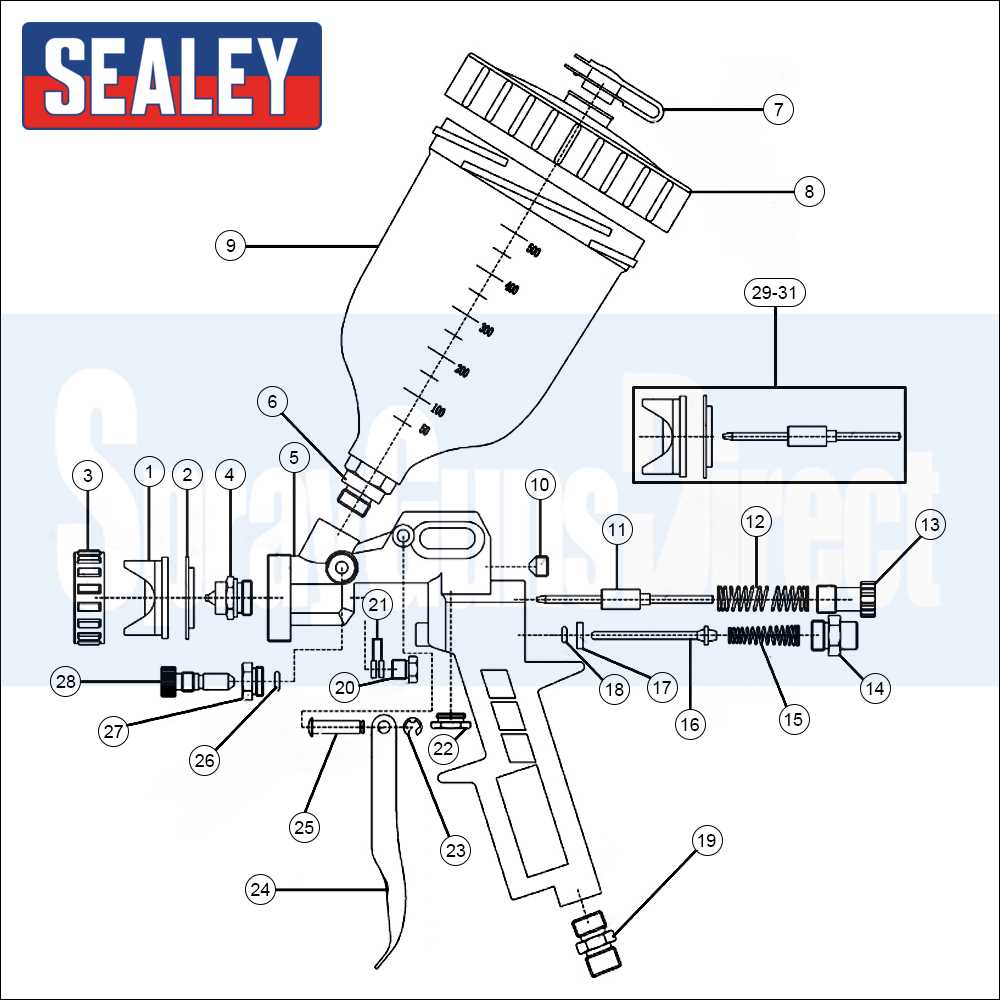

Cleaning and Lubrication

One of the most important aspects of maintenance is thorough cleaning after each use. Residue build-up can cause clogs and affect the performance of the tool. Carefully clean the internal and external parts, ensuring no excess material remains. Additionally, apply appropriate lubricants to moving parts to prevent wear and tear and ensure smooth operation during use.

Regular Inspections and Adjustments

Frequent inspections are crucial for detecting any wear or damage to the device. Check for loose connections, cracks, or signs of corrosion, and replace any damaged components immediately. Also, make sure the trigger mechanism and nozzle are functioning correctly by testing the flow and spray pattern. Regular adjustments will help maintain consistent application and prevent performance issues.