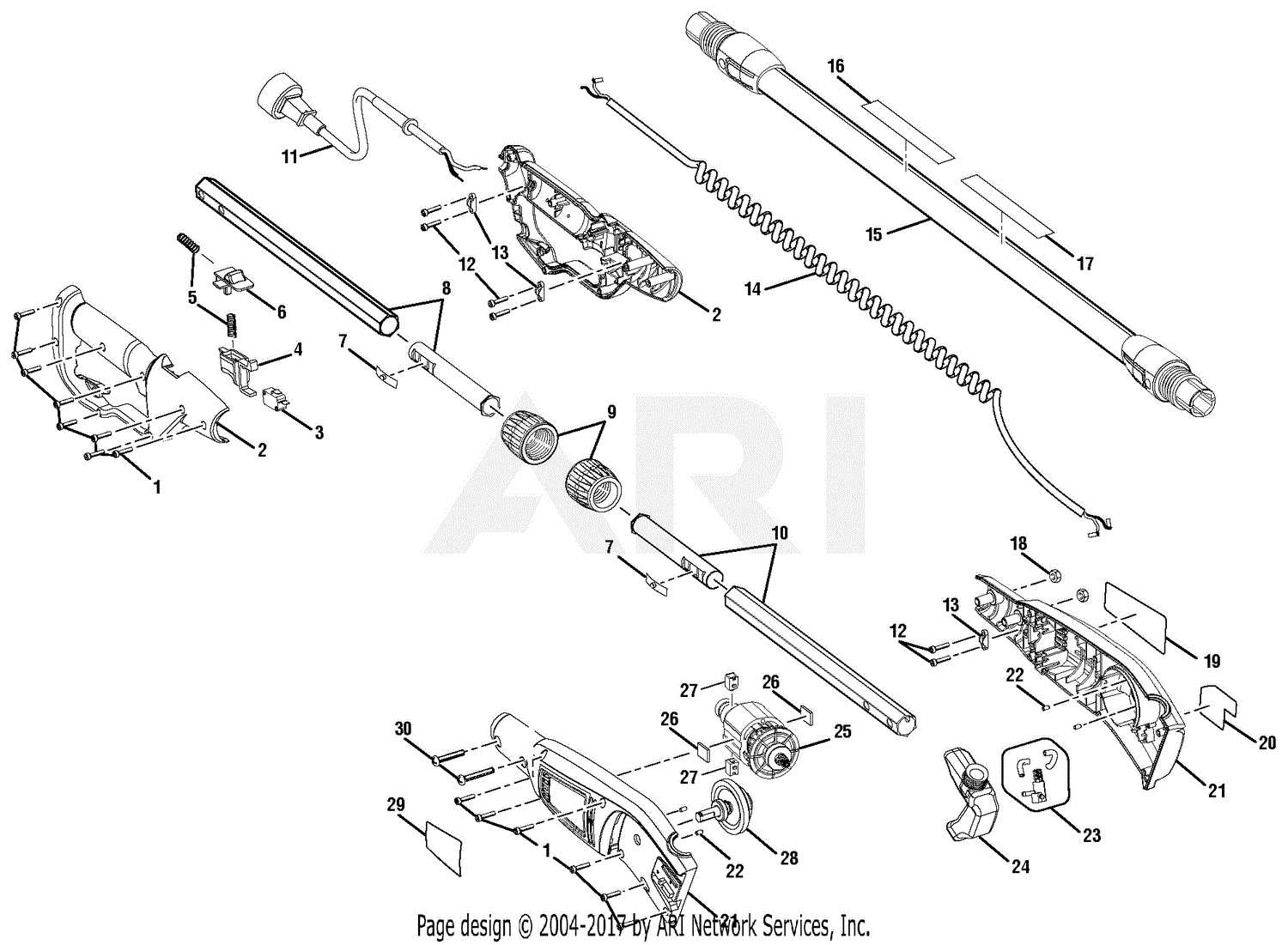

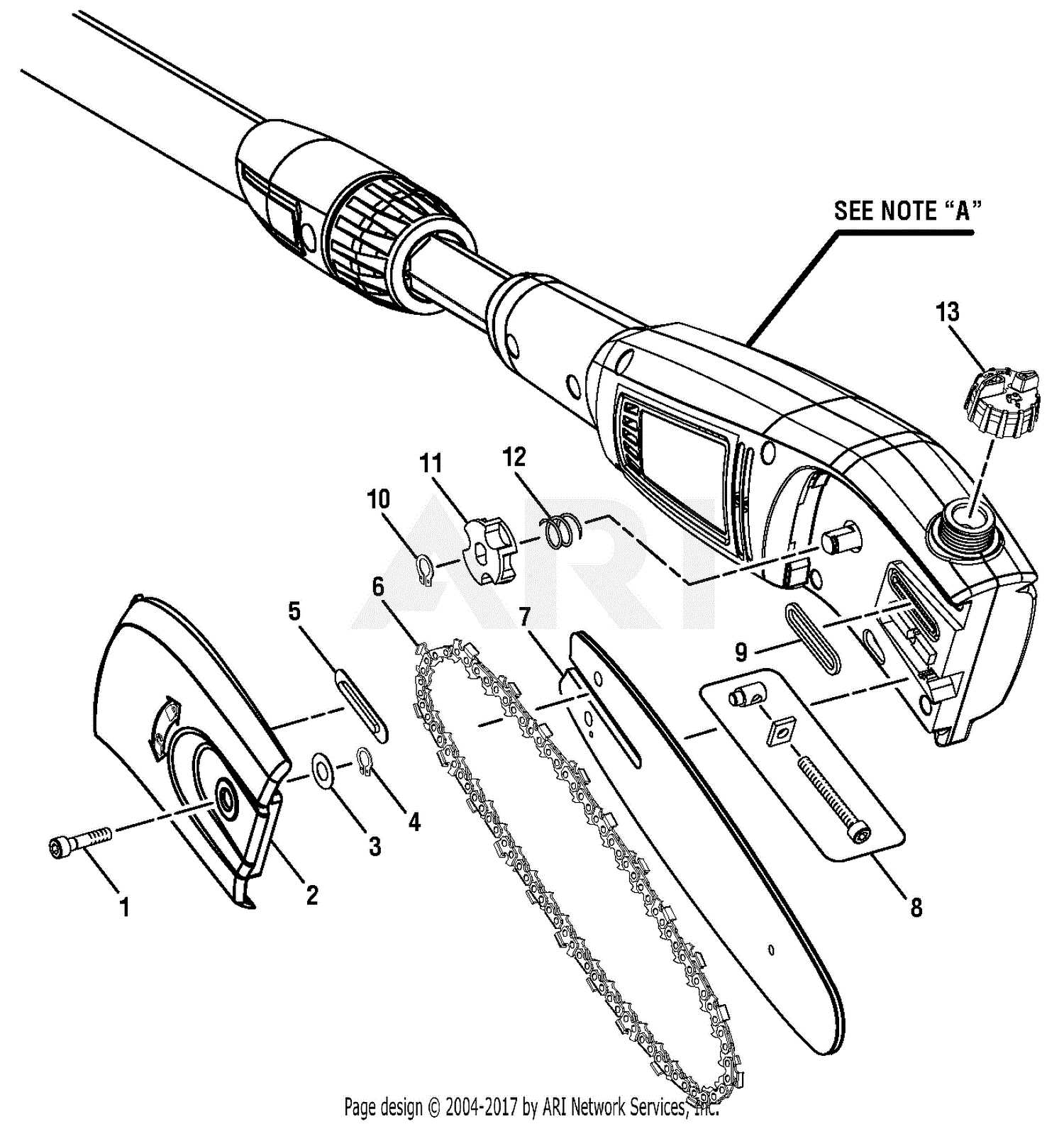

For efficient repairs and smooth operation, it is essential to understand the inner workings of your equipment. Knowing where each part fits and how it functions can save both time and money when maintaining or replacing components. Accurate identification ensures you’re selecting the right replacement parts and assembling the equipment correctly.

Having a clear reference to the specific components of a machine is invaluable for users, whether you’re performing routine maintenance or addressing an unexpected malfunction. A visual guide that outlines these elements in detail can make troubleshooting much simpler, helping you to resolve issues quickly.

Proper identification can enhance the lifespan of your equipment and prevent costly repairs. With the right approach, identifying each element becomes a straightforward process, allowing for effective upkeep and maximizing the performance of your tools.

Understanding the Equipment Component Reference

Knowing the layout and structure of your equipment is crucial for its proper maintenance. A well-organized visual guide to the internal elements provides clarity on each component’s location and function, simplifying the process of repairs and upgrades. This reference acts as a roadmap for users, helping them identify the right pieces and understand their purpose in the system.

How Visual Guides Assist in Maintenance

Visual aids are incredibly helpful when troubleshooting or replacing faulty components. A clear, detailed illustration shows how each element fits into the overall system, reducing errors during repair or replacement. With such a guide, users can quickly pinpoint the issue, choose the correct replacement, and restore functionality efficiently.

The Benefits of Knowing Your Equipment’s Layout

Familiarity with the layout of your tools not only ensures better maintenance but also increases safety. When users understand where each part is located and how they interact, the likelihood of making mistakes decreases significantly. This knowledge empowers users to take proactive care of their equipment, extending its life and performance.

How to Use the Equipment Component Reference Effectively

Using a component reference guide effectively requires a clear understanding of how to navigate the illustration and locate specific elements. It’s essential to know how each part is labeled and how the diagram visually represents the equipment’s internal structure. A careful review of the guide allows for quick identification and proper handling of each component, which can save time during repairs or maintenance.

Start by familiarizing yourself with the overall layout before jumping to specific parts. Identify the major sections of the machine and their corresponding components. This will help you to quickly locate the needed parts when troubleshooting or performing a repair. Additionally, always cross-check the components in the guide with the actual parts of your equipment to ensure accuracy and compatibility.

Common Components in Equipment

Understanding the most frequently used components in your equipment can make maintenance and repairs significantly easier. By recognizing the key elements that often require attention or replacement, users can quickly address issues and ensure their equipment operates smoothly. Here are some of the typical components you may encounter:

- Motor Assembly: The heart of the machine, responsible for driving most of the internal functions.

- Battery: Supplies power to the unit, making it essential for portability and operation.

- Handle: Provides the user with control and ease of movement during use.

- Switches and Controls: Regulate the machine’s settings and ensure safe operation.

- Wheels: Ensure mobility, especially for larger equipment designed for outdoor tasks.

Recognizing these components helps streamline the repair process. With this knowledge, users can avoid confusion, minimize downtime, and extend the lifespan of their tools.