Every outdoor enthusiast knows the importance of having reliable tools for managing their garden space. Maintaining and repairing these tools is essential for extending their lifespan and ensuring smooth performance. When something goes wrong, understanding the individual components and how they work together is the key to efficient repairs.

Familiarizing yourself with the structure of your garden devices can save both time and money. Recognizing each piece’s function allows you to pinpoint issues more quickly and address them without needing professional help. Whether you’re dealing with broken or worn-out sections, understanding how each part operates is crucial for restoration.

In this guide, we’ll explore the various elements that make up a typical garden tool system, provide helpful instructions for common repairs, and offer tips for optimal performance. Mastering the details will make fixing or replacing damaged components straightforward, ensuring your equipment is ready for the next season of work.

Understanding Garden Equipment Components

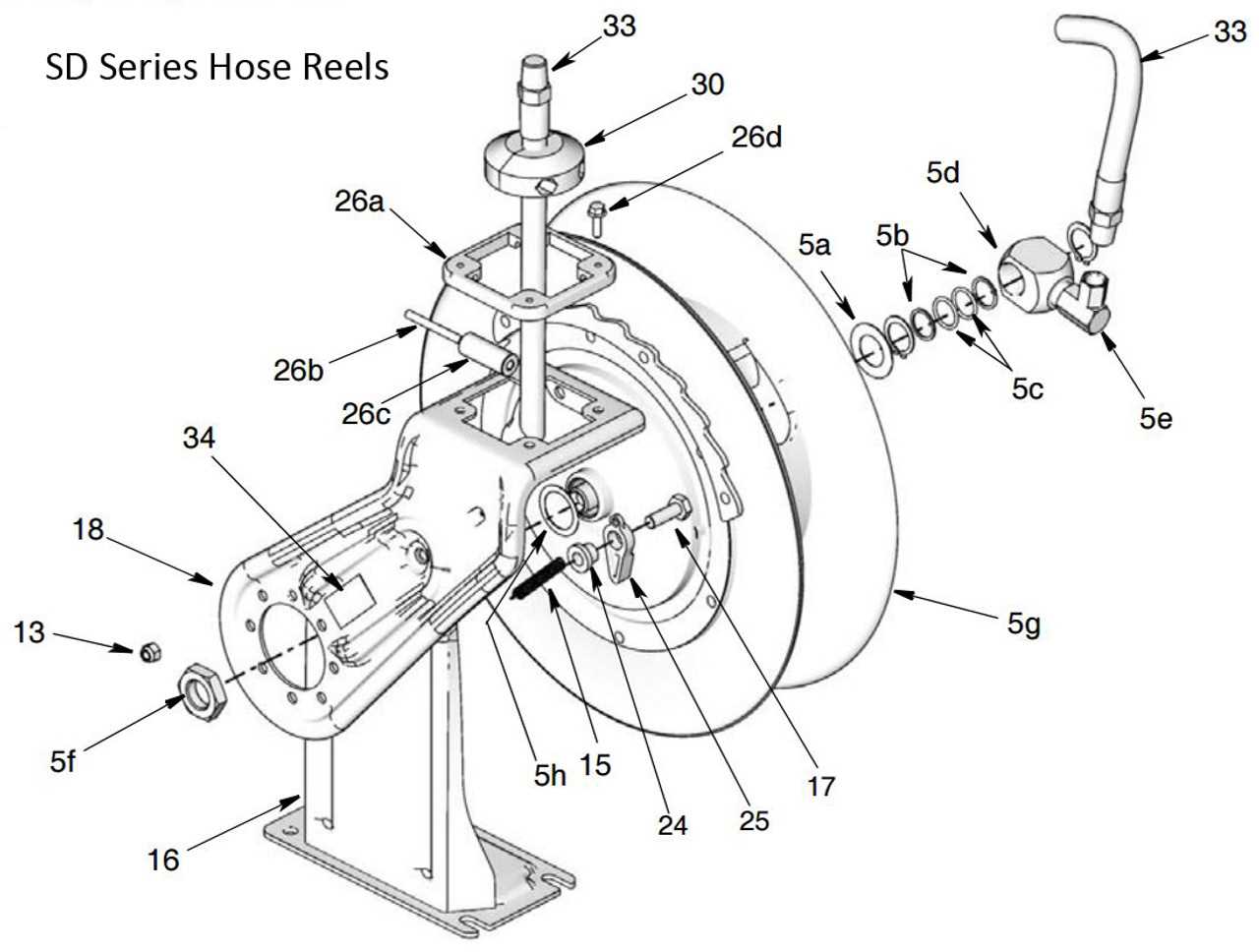

To keep your outdoor tools in peak condition, it is crucial to understand how the different sections of your equipment work together. Each component plays a vital role in the overall performance and functionality of the tool, from the mechanism that helps you wind and unwind to the various connectors that secure the system. Gaining insight into these elements ensures that any repair or maintenance task is done efficiently.

Key Elements of the System

The key components of such devices typically include the winding mechanism, support frame, and locking system. Each part serves a specific purpose in managing the tool’s operation. The winding mechanism, for example, allows the stored item to be coiled or uncoiled with ease, while the support frame holds everything in place, ensuring stability during use. The locking mechanism prevents the coil from unwinding when not in use.

Importance of Proper Maintenance

Understanding each part’s role is only the first step. Regular maintenance and timely replacement of any damaged elements will help you avoid larger issues down the line. Knowing how to identify the source of a malfunction and which components need attention can drastically reduce downtime and improve the longevity of your equipment. By staying on top of these details, you can keep your garden tool functioning optimally throughout the seasons.

How to Identify Damaged Parts

Identifying the components that are malfunctioning is the first step in resolving any issue with your garden tools. Over time, wear and tear can cause certain sections to break down, affecting the overall function. Knowing how to spot these problems early on can prevent more extensive damage and save you from costly repairs or replacements.

Start by examining the equipment for any visible cracks, dents, or broken pieces. These are often signs of physical damage. Listen for unusual sounds when the tool is in use, as grinding or squeaking noises may indicate that parts are misaligned or worn out. Additionally, check for any loose or missing fasteners, as these can compromise the stability of the entire system.

It is also important to assess the function of the components individually. If the mechanism doesn’t wind properly or fails to lock into place, it could be due to a malfunction in the internal gears or springs. Thoroughly inspecting each element, from the external housing to the internal mechanism, will help pinpoint exactly where the issue lies and guide you towards the necessary fixes.

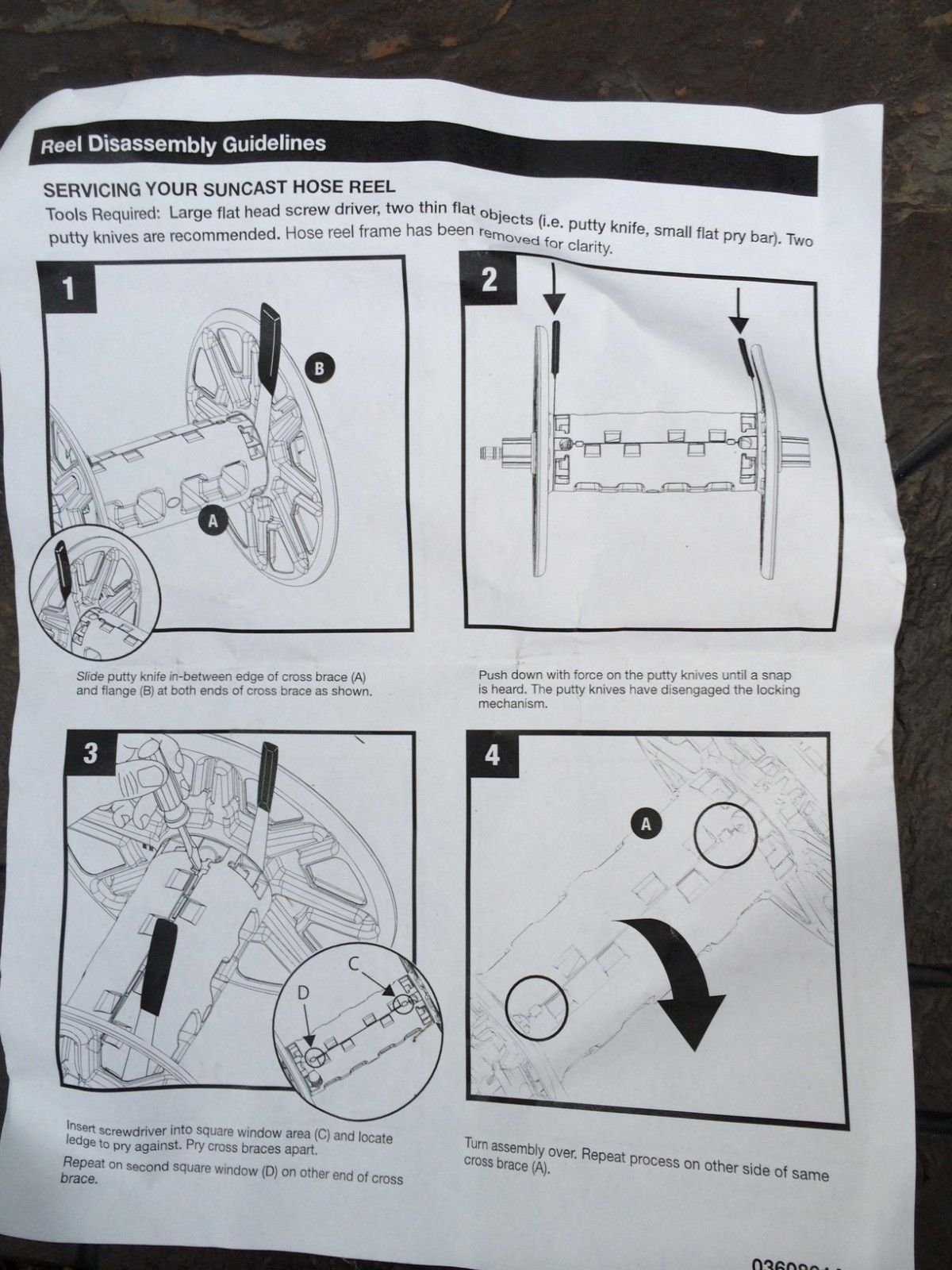

Step-by-Step Repair Guide

Repairing malfunctioning garden tools can seem daunting, but breaking the process into manageable steps makes it easier. Whether you’re fixing a mechanical issue or replacing worn components, following a structured guide will help ensure you complete the task correctly and efficiently. A clear understanding of how each section of the device functions is crucial to troubleshooting and making repairs.

Begin by gathering the necessary tools and replacement parts. Make sure you have everything you need before starting to avoid unnecessary interruptions. Start by disconnecting the equipment from any power source or securing the device in a stable position to prevent accidents. Carefully remove any damaged sections and take note of how the components are assembled. This will help you reassemble the tool correctly after the repair is completed.

Next, inspect each piece closely for signs of wear or damage. Replace any parts that are broken or no longer functioning as intended. Pay attention to the alignment and make sure all fasteners are tightened securely before reassembling. Once everything is in place, test the tool to ensure it operates smoothly. Regular checks and maintenance will keep your equipment in top working condition, prolonging its life and preventing further issues.