Air circulation systems are essential for maintaining comfort in many environments, especially in hot and dry conditions. Knowing how these systems work is crucial for ensuring their optimal performance and longevity. A clear understanding of each component’s role can help in troubleshooting, maintenance, and repairs.

When looking at these systems, it is important to recognize the different elements that contribute to their function. Each piece has a specific job that helps the system operate efficiently, whether it’s for cooling or moisture regulation. By learning how to identify and understand these components, users can address issues more effectively.

Regular maintenance and care are key to extending the life of these systems. Identifying malfunctioning parts early on can save time and money in repairs. A detailed guide to these systems’ individual components can empower users to take action before small problems turn into larger, more costly ones.

Understanding Swamp Cooler Components

The efficiency of air circulation systems depends on the proper functioning of each individual component. Recognizing how each element contributes to the system’s overall performance is essential for troubleshooting and maintenance. A thorough understanding helps in diagnosing problems and ensuring the system runs smoothly for extended periods.

Each section of the system works in harmony, from the intake fans that draw in air to the mechanisms that filter and cool it. The cooling process itself is influenced by various components that control the flow of air, water, and temperature. Proper care and regular checks on these elements are necessary to maintain an optimal environment.

By familiarizing yourself with each component’s role, you can easily identify potential issues. Whether it’s the fan motor, the water distribution system, or the filter pads, knowing what to look for allows for quick fixes and proper upkeep. This approach not only saves time but also extends the lifespan of the system.

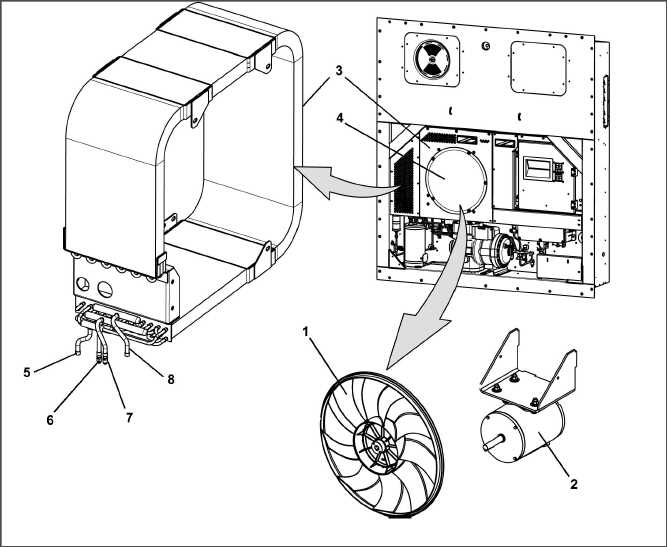

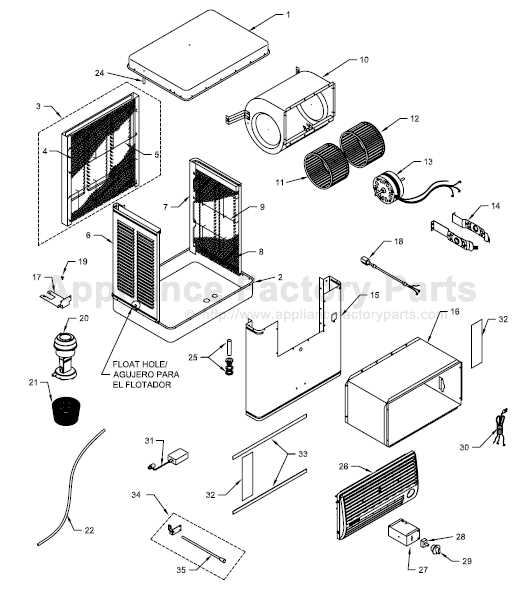

How to Identify Key Cooler Parts

Understanding the key elements that make up an air circulation system is essential for effective maintenance and troubleshooting. By recognizing the core components, you can easily pinpoint issues and perform repairs when necessary. Familiarity with each section helps users to make informed decisions about care and improvements.

Identifying the Primary Components

The most important elements of an air circulation system are typically the fan motor, water distribution system, and filters. These components play a central role in how air is circulated and cooled. The fan motor controls airflow, while the water system regulates moisture levels. The filters ensure that the air remains clean and free of debris.

Spotting Signs of Malfunction

Knowing how to spot early signs of failure in each part is crucial. For example, if the airflow is weaker than usual, the fan motor may need attention. If there’s insufficient cooling or excess moisture, the water system or filters could be at fault. Regular inspection of these components ensures that the system continues functioning optimally for longer periods.

Importance of Proper Maintenance for Components

Regular upkeep of the individual elements in an air circulation system is crucial to ensure its long-term functionality. Proper maintenance prevents wear and tear, reduces the likelihood of breakdowns, and helps maintain energy efficiency. Without attention to detail, small issues can escalate into costly repairs.

By keeping components in top condition, you can extend the lifespan of the system and ensure it operates at peak performance. Regular cleaning, lubricating, and inspecting key elements such as motors, filters, and water distribution systems are essential practices. These steps not only prevent malfunctions but also contribute to better air quality and overall system efficiency.

Maintaining each element properly also saves money in the long run by avoiding premature replacements and unnecessary repairs. Identifying potential problems early on ensures that corrective measures can be taken before damage becomes significant. A well-maintained system operates more efficiently, which can also lower energy consumption.