When it comes to maintaining complex machinery, having a clear visual reference to its internal structure is crucial. Knowing the location and function of each individual element ensures efficient repairs and replacements. A well-detailed illustration can save time and reduce the risk of errors during servicing.

Detailed visual aids allow users to quickly identify components, understand their roles, and avoid common issues. Whether for maintenance or upgrades, understanding the layout of a system is the first step towards ensuring longevity and peak performance.

Accurate identification of each piece can make troubleshooting much simpler, helping to pinpoint malfunctioning areas and streamline the repair process. This guide will provide you with the essential information needed to get the most out of your equipment.

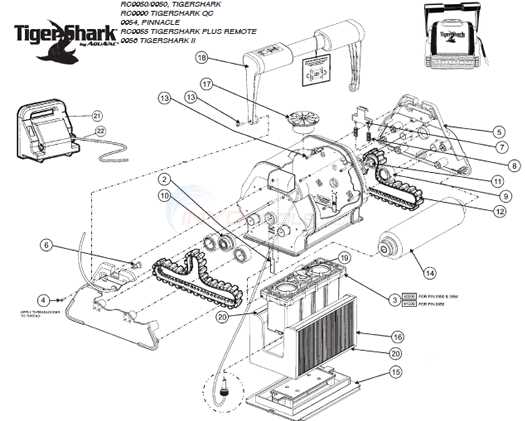

Understanding the Swimpro Voyager Parts

Effective operation of any mechanical system relies on understanding the structure and functions of its various components. Identifying and familiarizing yourself with each element allows for better maintenance and faster troubleshooting. Knowing how each piece interacts within the overall design ensures smoother performance and less downtime.

Main Functional Elements

Each component within a system serves a specific purpose. The proper functioning of these elements is essential for seamless operation. Below are the primary groups of components you need to recognize:

- Drive system – Powers the machine and ensures movement.

- Control mechanisms – Allow the user to adjust settings and directions.

- Housing and protection – Encloses internal parts and protects them from external damage.

- Cleaning system – Handles the effective cleaning operation, usually involving brushes or suction elements.

Key Benefits of Understanding the Components

Having a solid grasp of how each part functions can significantly enhance your ability to maintain and repair the machine. Here are a few key advantages:

- Improved troubleshooting – Quick identification of issues leads to faster fixes.

- Informed replacements – Knowing the components makes choosing replacements easier and more accurate.

- Extended lifespan – Proper understanding results in more effective care and fewer breakdowns.

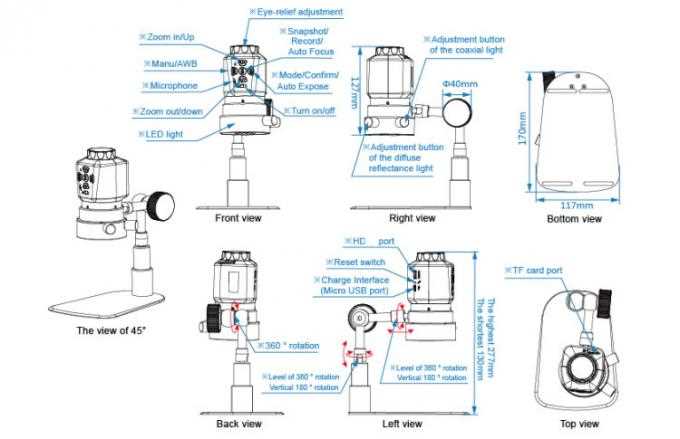

How to Use the Parts Diagram Effectively

A visual reference for mechanical systems can be an invaluable tool when working on repairs or maintenance. It provides a clear representation of how different components fit together and interact, allowing you to pinpoint issues quickly and efficiently. Using this guide properly can significantly improve the accuracy and speed of your work.

Step-by-step approach is essential when consulting a visual reference. Start by identifying the main sections, and then narrow your focus to individual components. This structured method helps you avoid confusion and ensures you are addressing the right part of the system.

Focus on labels and indicators that highlight key elements. Many guides use clear symbols or part numbers to help you match components with their corresponding locations. Understanding these details is vital to avoid mistakes, especially when parts are similar in appearance.

- Start with the overview – Familiarize yourself with the broad structure before zooming in on specific components.

- Highlight connections – Pay attention to how parts connect or interact to fully grasp the system’s design.

- Use part numbers and labels – Refer to the corresponding list for accurate identification and avoid confusion.

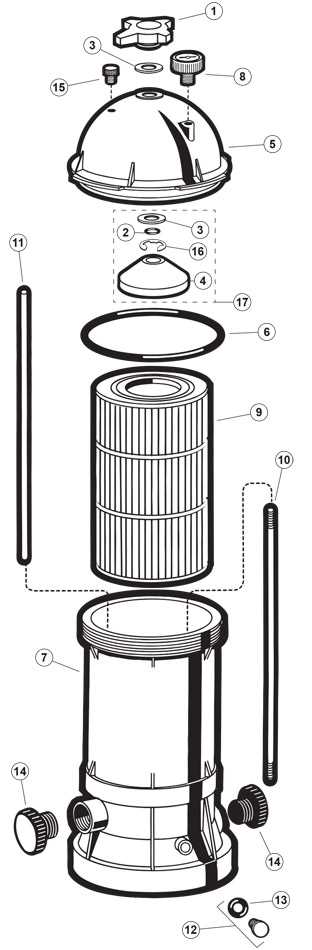

Identifying Common Components

Recognizing the most essential elements of any machine is crucial for ensuring its proper functioning. Familiarity with the common components helps when it’s time for maintenance or troubleshooting, making the repair process more straightforward and reducing the chance of errors. Each system typically contains a set of key parts that play vital roles in overall performance.

Primary Functional Elements

The most commonly found components in this type of system are designed to handle specific tasks. Understanding their role allows you to quickly address issues or upgrade individual elements. Below are some of the core components you will encounter:

- Drive mechanism – This part is responsible for powering the system and ensuring movement, often involving motors or gears.

- Control interface – Enables users to interact with the system, adjusting settings or operational parameters.

- Protective housing – Shields internal components from damage or wear due to external factors.

- Operational tools – These include brushes, filters, or suction mechanisms that perform the cleaning or functioning duties.

Maintenance Tips for Key Elements

Proper care and attention to these core components are necessary for maintaining optimal performance. Here are some simple tips for effective maintenance:

- Regular cleaning – Keeping tools and moving parts clean ensures that they function smoothly and efficiently.

- Inspecting connections – Ensuring all parts are securely connected prevents malfunctions during operation.

- Timely replacements – Swap out worn-out elements promptly to avoid further damage or inefficiencies.

Step-by-Step Guide to Component Replacement

Replacing faulty or worn-out elements in a system requires precision and attention to detail. Following a systematic approach ensures the process is efficient, reduces the risk of damaging other components, and restores the machine to its optimal condition. With the right preparation and tools, you can carry out replacements effectively.

Preparation and Safety

Before starting the replacement process, take necessary precautions to ensure your safety and the success of the task:

- Turn off the power – Always disconnect the machine from its power source to avoid electrical hazards.

- Gather the right tools – Ensure you have all necessary tools and replacement components within reach.

- Read the manual – Familiarize yourself with the specific instructions for replacing the part.

Step-by-Step Replacement Process

Once you are prepared, follow these steps to replace the component:

- Step 1: Identify and locate the damaged or worn component using a guide or reference.

- Step 2: Carefully remove any surrounding parts that may obstruct access to the faulty component.

- Step 3: Disconnect the damaged component from the system, taking note of its connections for the new one.

- Step 4: Install the replacement part, ensuring it fits properly and connects securely.

- Step 5: Reassemble any parts removed earlier and check for any loose connections.

- Step 6: Test the system to ensure the new component works properly and everything functions as expected.

Common Issues with Mechanical Components

Every mechanical system is susceptible to certain issues over time due to wear, external factors, or improper maintenance. Identifying these problems early is key to ensuring the machine continues to operate smoothly and efficiently. Understanding common issues with internal components helps prevent unnecessary downtime and costly repairs.

One of the most frequent challenges faced is component degradation, which occurs as parts are exposed to constant use and wear. Elements like gears, motors, and brushes can wear out, affecting the system’s performance. In addition, external factors such as dirt buildup or environmental conditions can exacerbate these problems.

Misalignment of key parts is another issue that can disrupt operation. If parts are not properly connected or aligned, the system may experience performance issues, including uneven movement or reduced efficiency.

Other common concerns include blockages or clogs that hinder the flow of materials or fluids within the system. Regular cleaning and maintenance can significantly reduce the occurrence of these problems, keeping the system running smoothly.