When it comes to repairing or maintaining your shower system, understanding its components is crucial. Each element plays a specific role, and knowing how they function together can save you time and money. A clear overview of all the essential parts will help you identify any issues quickly and accurately.

By examining the layout of your system, you can easily pinpoint the necessary components for troubleshooting or replacements. Whether you’re a DIY enthusiast or a professional plumber, having a visual reference and a solid understanding of the components can make the process much more efficient.

Proper maintenance ensures your shower runs smoothly for years, preventing costly repairs and extending its lifespan. Taking the time to learn about the individual parts will give you the confidence to tackle any issues that arise.

Understanding Shower System Components

Every shower system consists of several key elements that work together to ensure smooth operation. These components include valves, handles, cartridges, and various fittings, all of which contribute to controlling water flow and temperature. Understanding how each part functions and interacts with others is essential for efficient repairs and maintenance.

The valve, for example, is the central mechanism that regulates water pressure and temperature. The handle controls the valve, allowing users to adjust settings. Other crucial elements, like seals and cartridges, ensure water flows correctly and prevent leaks. A comprehensive knowledge of these components helps in identifying the root cause of any malfunction.

Familiarizing yourself with the layout and function of each part can significantly simplify maintenance tasks, reducing the risk of errors during repairs. Whether replacing a faulty component or performing a routine inspection, knowing what each part does and where it fits into the overall system can save both time and effort.

How to Identify Shower System Components Easily

Identifying the components of your shower system is an important step in diagnosing and fixing any issues. With so many different elements involved, it can be challenging to know which part needs attention. Fortunately, understanding the basic layout and function of each piece can make identification straightforward.

Visual Cues and Labels

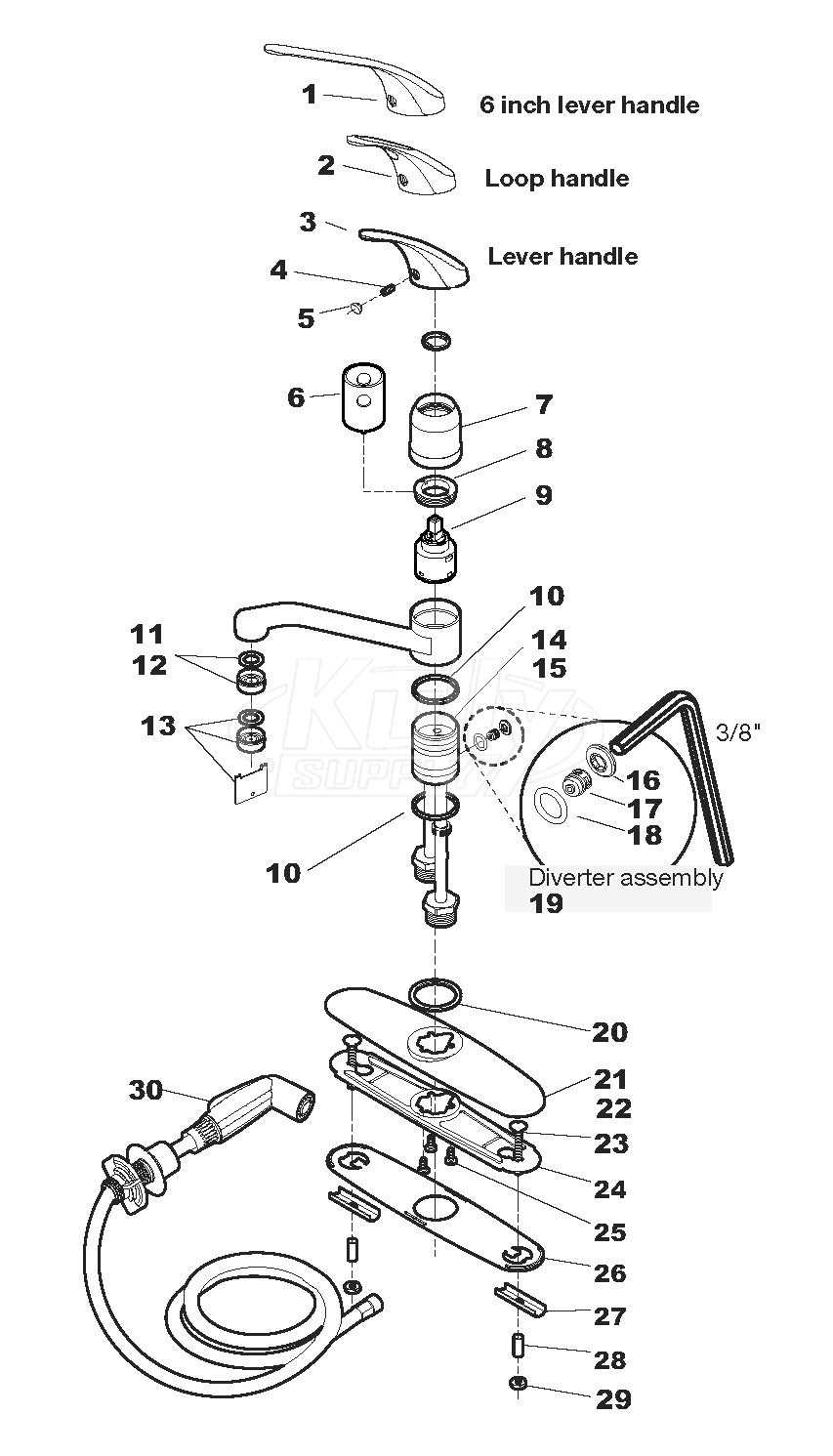

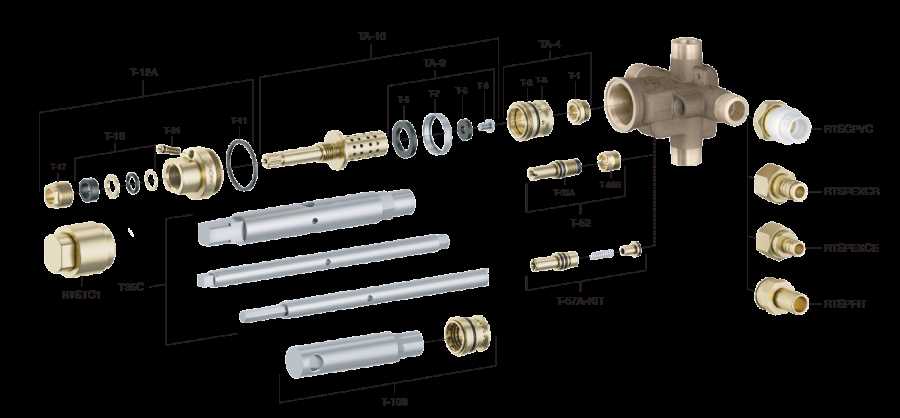

One of the simplest ways to identify individual components is by looking for visual markers or labels. Most shower systems have clear markings on the valve handles, temperature controls, or cartridges, which indicate their specific function. These labels can guide you in quickly locating the malfunctioning part and determining the necessary replacement.

Referring to Manufacturer Documentation

In some cases, you may need to consult the manufacturer’s documentation for a more detailed breakdown. Diagrams and part lists provided by the manufacturer can be extremely helpful for locating and identifying specific components. By cross-referencing your system with the provided guide, you can pinpoint exactly which part needs repair or replacement.

Common Issues with Shower Control Systems

Shower control systems, while built to last, can experience various issues over time. These problems typically arise due to wear and tear, improper installation, or lack of maintenance. Understanding the most common issues can help you troubleshoot and resolve problems effectively, restoring your shower to full functionality.

Temperature Fluctuations

One of the most frequent problems users encounter is temperature fluctuations. This issue can occur if the valve or cartridge responsible for regulating water temperature becomes worn or damaged. When this happens, the water may suddenly become too hot or too cold, making the shower uncomfortable. Replacing the faulty component is usually the most effective solution.

Leaks and Drips

Leaks and drips are another common issue with shower systems. Over time, seals and gaskets can degrade, causing water to escape from the system. Leaking water not only wastes resources but can also lead to water damage around the shower area. Regular inspections and replacing any worn-out seals can help prevent these issues.