Understanding the inner workings of small engines is essential for proper maintenance and efficient repairs. A clear visual guide to the engine’s individual parts can save time and prevent costly mistakes. When dealing with mechanical issues, knowing the correct placement and function of each element helps ensure smoother operations and more accurate fixes.

By exploring a comprehensive visual map of the engine’s components, users can gain insight into how each piece contributes to the overall performance. This resource is especially helpful for those looking to troubleshoot problems, replace faulty elements, or simply perform routine maintenance with confidence.

Whether you are a seasoned technician or a DIY enthusiast, having access to a detailed breakdown of engine elements will help you work more effectively. With a solid understanding of the components, diagnosing issues becomes easier, leading to quicker and more efficient repairs.

Understanding TC II Engine Components

To effectively maintain and repair small engines, it is crucial to have a solid understanding of how each component works together. Every part plays a specific role in ensuring the engine runs smoothly, and identifying these pieces is key to diagnosing issues. A visual map of the engine can provide clarity and guide you in recognizing the various elements and their functions.

Main Engine Assembly

The central assembly of the engine is the heart of its operation. This includes the core mechanisms that drive the engine, such as the crankshaft, piston, and flywheel. These parts work in unison to convert fuel into mechanical energy, powering the entire system. A breakdown of these components helps you understand how energy is transferred throughout the engine.

Supporting Systems

Beyond the main assembly, other systems ensure the engine performs optimally. The fuel system, including the carburetor and fuel lines, is responsible for delivering the right mixture of air and fuel to the engine. Similarly, the ignition system, consisting of the spark plug and related components, ignites this mixture to initiate combustion. Understanding the function of each of these systems allows for easier troubleshooting and more effective repairs.

How to Read the Parts Diagram for TC II

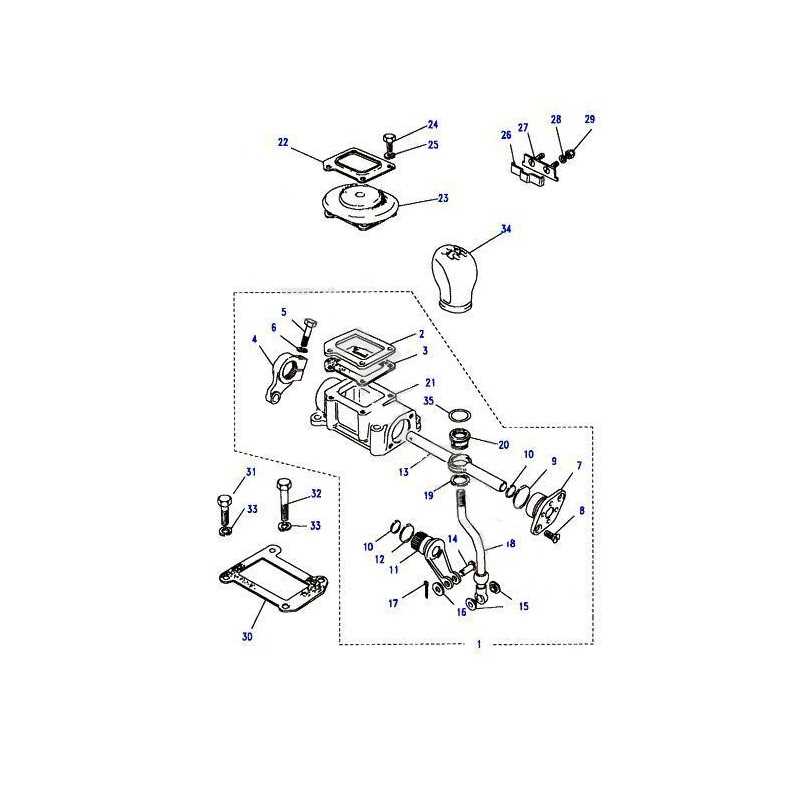

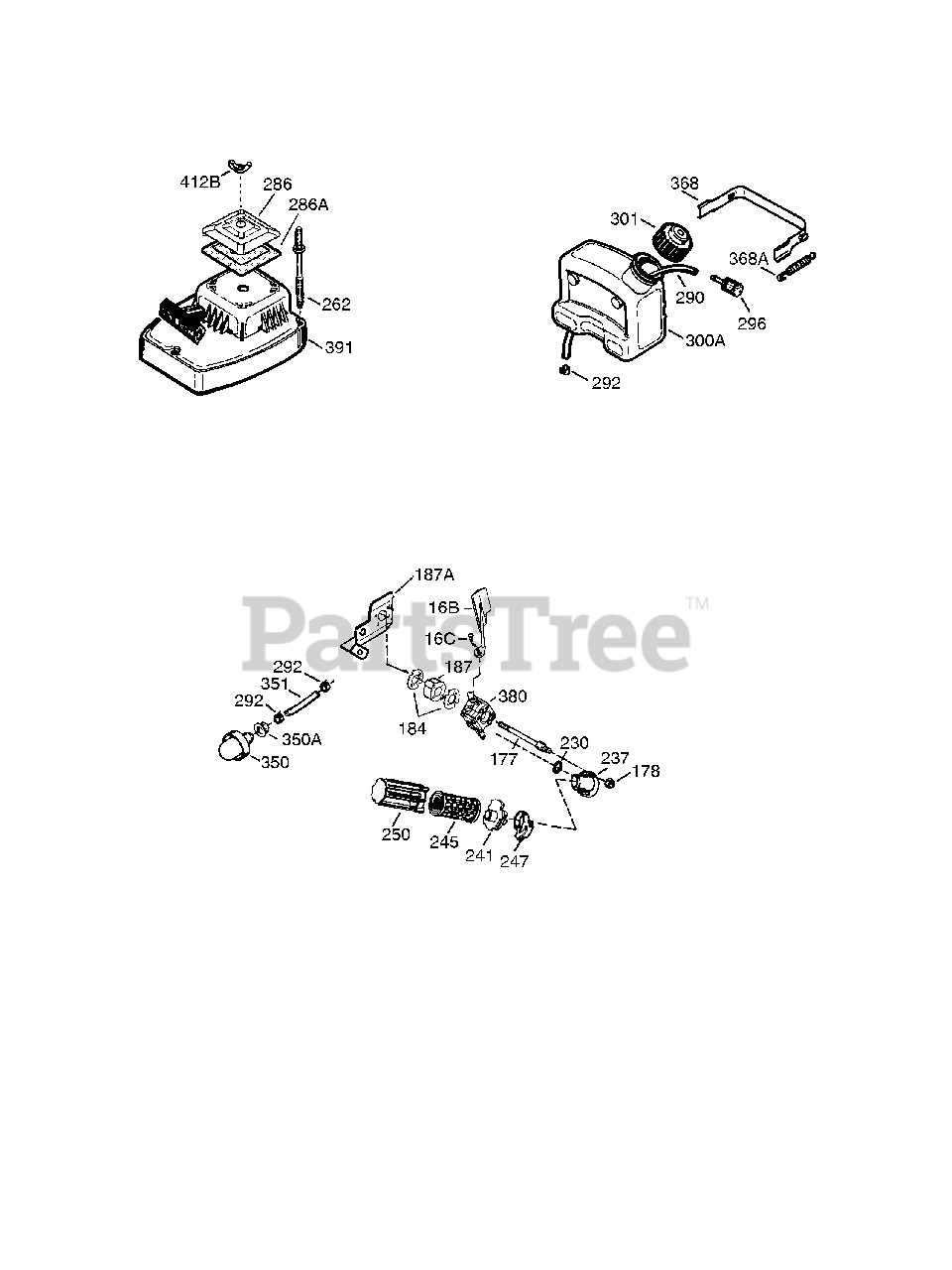

Reading an engine breakdown is an essential skill for anyone working on engine repairs or maintenance. A visual guide can simplify the process by showing each component in relation to others, making it easier to identify parts, locate issues, and replace damaged elements. Understanding how to interpret these visuals will help you save time and avoid confusion during repairs.

Understanding Labels and Numbers

One of the first things to look for in an engine schematic is the system of labels and numbers associated with each part. These identifiers correspond to detailed lists where each number represents a specific component. This system helps you match the visual representation with the actual item, ensuring you order the correct replacement part or focus on the right area for repairs.

Identifying Relationships Between Components

Engine visuals typically show how components interact with each other. Pay close attention to the way different parts connect or align, as these relationships are crucial for understanding how the engine functions. Recognizing these connections will allow you to troubleshoot effectively, whether you’re addressing a mechanical failure or performing routine maintenance.

Common Issues and Repairs for TC II Engines

Engines can develop a variety of issues over time, especially with regular use. Common problems often arise from wear and tear, incorrect maintenance, or poor fuel quality. Identifying these issues early and understanding the necessary repairs is key to extending the lifespan of your engine and avoiding costly replacements.

One frequent issue is poor starting, which can be caused by a variety of factors such as a clogged fuel system, a faulty ignition system, or a weak battery. Another common problem is loss of power, which may be attributed to issues like air filter blockages, carburetor malfunctions, or compression loss. Diagnosing these problems quickly can save time and prevent further damage.

Repairs typically involve cleaning or replacing components such as spark plugs, fuel lines, or air filters. In some cases, more extensive repairs like carburetor cleaning or valve adjustments may be necessary. Understanding the root cause of the problem is crucial for ensuring a proper fix and avoiding recurring issues.