Every machine relies on a complex network of individual parts that work together to ensure its proper functioning. Familiarizing yourself with how these components are organized and interact is essential for effective maintenance and repairs. When problems arise, having a visual reference to identify and locate these parts can make the process much smoother.

In this section, we explore how to understand the layout of the key elements within your equipment. Whether you’re performing routine checks or dealing with a specific malfunction, knowing where each piece fits into the bigger picture is crucial. This guide aims to provide clarity and ease when it comes to identifying what needs attention, making repairs more manageable and efficient.

Understanding Equipment Component Breakdown

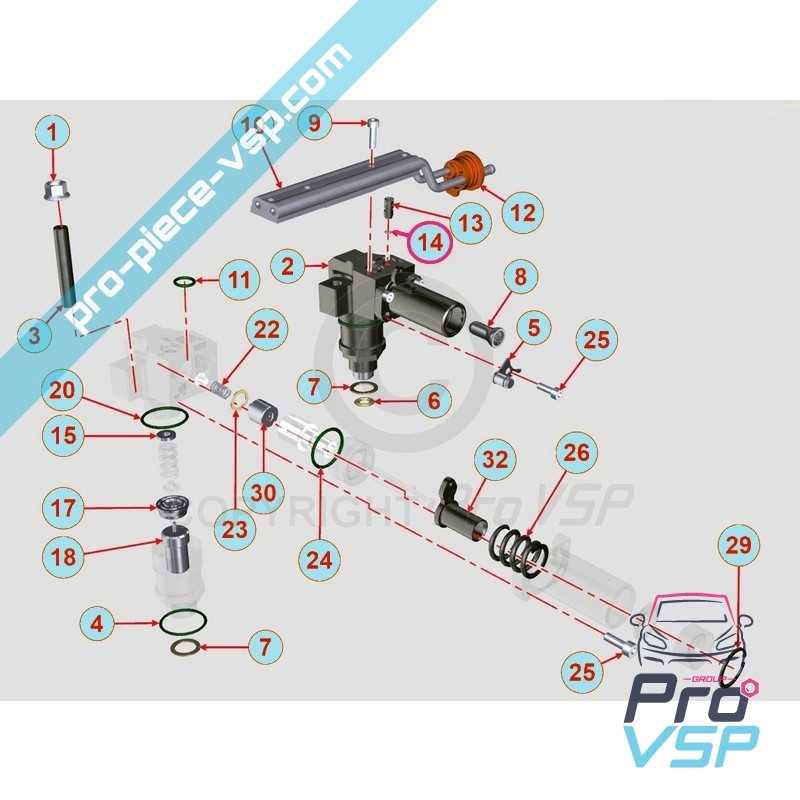

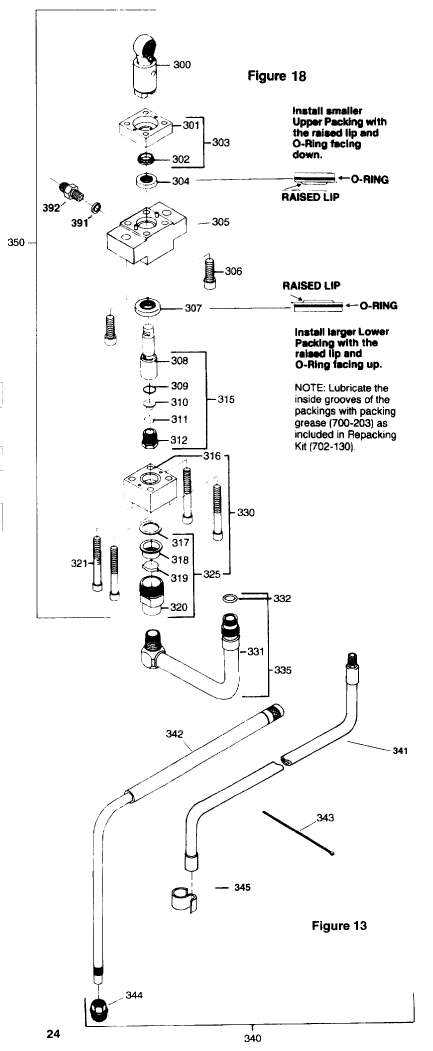

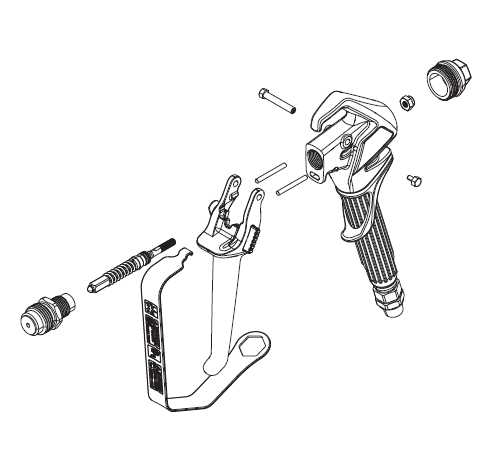

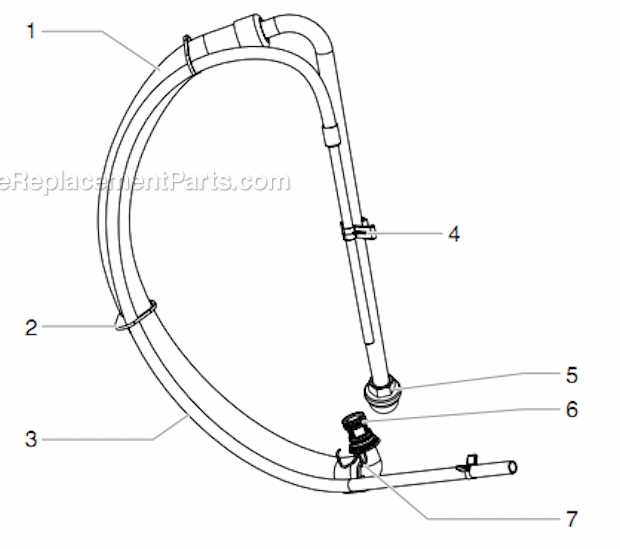

In any complex machinery, a clear representation of its internal structure is essential for effective troubleshooting and maintenance. This visual guide helps you familiarize yourself with how different components interact, making it easier to locate and replace worn or damaged pieces. Knowing where each component is located and how it functions within the system will enhance your repair skills and overall understanding of the equipment.

How Visual References Aid in Maintenance

Visual guides provide a clear, organized overview of the machine’s internal layout, highlighting each element’s position and function. By using this reference, you can quickly pinpoint potential issues, saving time and reducing the risk of mistakes. Whether you’re looking to perform basic servicing or addressing specific faults, a well-organized schematic is a powerful tool.

Benefits of Detailed Equipment Layouts

Having access to a comprehensive layout offers several advantages, including minimizing downtime and avoiding unnecessary parts replacements. With a well-detailed map of your machine’s components, you can prioritize repairs, plan efficient maintenance, and extend the overall life of your equipment. It ensures that each action is based on accurate information, leading to faster resolutions and improved performance.

How to Identify Key Components of Equipment

Properly identifying the crucial elements of any machine is vital for efficient repairs and maintenance. Each part has a specific role in the system’s operation, and understanding these roles allows you to address issues with precision. Knowing how to locate and distinguish between the different components can significantly reduce the time spent diagnosing problems and make your work more effective.

Start with the Basics

The first step in identifying essential components is to familiarize yourself with the machine’s overall layout. Begin by studying the main sections of the equipment, such as the power source, control mechanisms, and functional units. Once you have a general understanding, narrow down your focus to the specific parts that are most likely to wear out or need maintenance regularly.

Using Reference Materials for Accurate Identification

Detailed reference materials, such as exploded views or system layouts, can help pinpoint each component’s location. These guides provide a clear picture of how everything fits together, allowing you to track down the exact part you’re working on. Make sure to cross-reference with these materials during any repair or inspection to ensure accuracy and avoid errors that could impact the machine’s performance.

Step-by-Step Guide to Equipment Repairs

Repairing any complex machinery requires a methodical approach to ensure everything is handled properly and the equipment is restored to its optimal function. Following a step-by-step process helps break down the repair into manageable tasks, preventing confusion and mistakes. This guide will walk you through the essential stages of performing a repair, from preparation to completion, with tips for a smooth workflow.

Step 1: Assess the Issue

Before you start any repair, it’s crucial to identify the problem. Carefully examine the equipment to pinpoint signs of wear, damage, or malfunction. Look for unusual sounds, leaks, or performance issues that can indicate what part of the machine requires attention. Once you’ve determined the root cause, make a list of the necessary tools and components for the fix.

Step 2: Disassemble with Care

Once you’ve gathered your materials, begin the disassembly process. Take your time to carefully remove any parts that need replacement or repair, ensuring that you don’t damage any other components in the process. Keep track of each part’s order and position so that reassembly goes smoothly. If necessary, document or photograph each step to avoid confusion later on.

Step 3: Replace and Reassemble

After the old or damaged components are removed, replace them with new or functional parts. Ensure that each piece is fitted properly and securely. Once everything is replaced, begin the reassembly process, carefully following the reverse order of disassembly. Double-check each step to ensure no parts are left out or improperly installed, which could affect the machine’s performance.

Step 4: Test and Verify

After reassembly, it’s essential to test the equipment to verify that the repair was successful. Run the machine through its normal operations, checking for any signs of malfunction or performance issues. If everything operates as expected, your repair is complete. If any problems persist, retrace your steps to ensure that everything was correctly addressed.