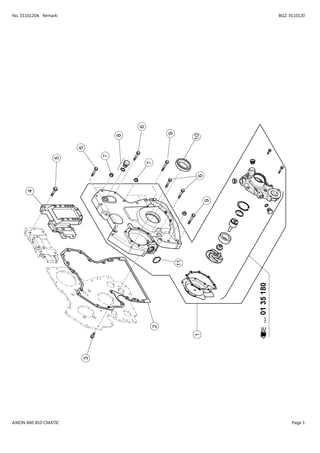

In any mechanical system, knowing the arrangement and function of individual elements is crucial for proper maintenance and troubleshooting. A well-organized map of these components can help users identify each part’s role and simplify the repair process. Having access to a clear representation of how each section connects enables quicker and more efficient work when dealing with issues.

Detailed visual guides allow operators to locate specific pieces, assess their condition, and replace them when necessary. Whether you are a seasoned professional or a beginner, understanding the internal structure of complex systems is essential for maintaining optimal performance and avoiding unnecessary downtime.

Familiarity with the layout not only ensures that users can fix problems promptly but also aids in the regular upkeep of equipment to prevent future failures. This guide will walk you through the essentials of navigating and interpreting detailed breakdowns for a better overall understanding of the machinery’s design and maintenance needs.

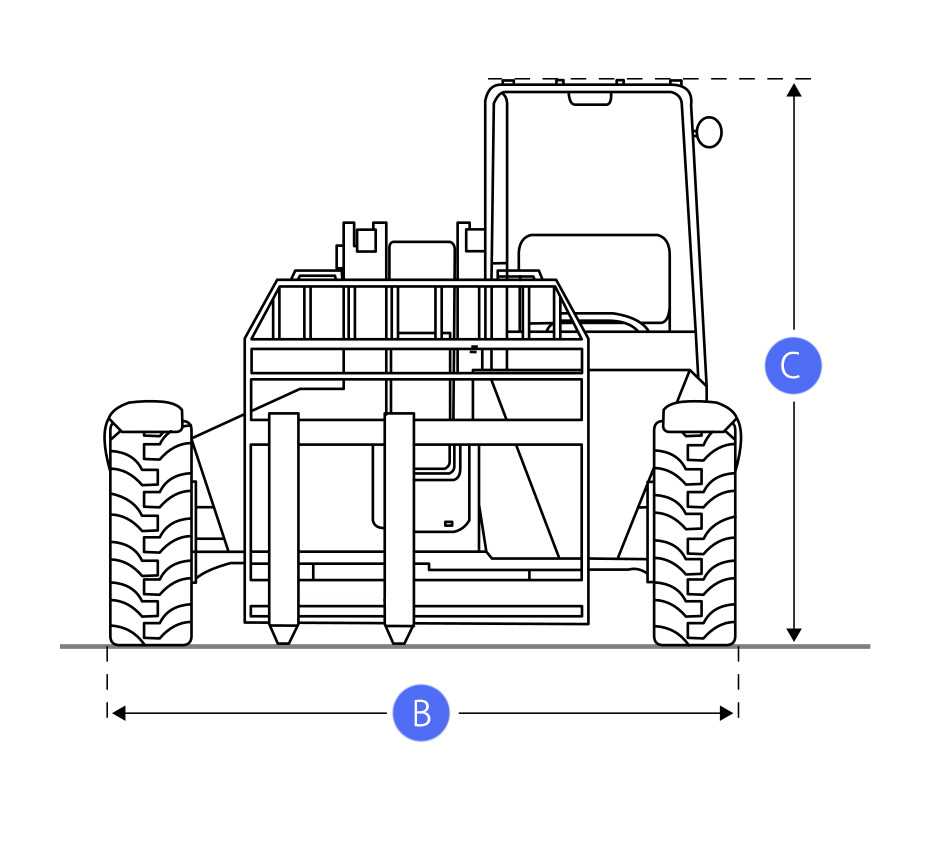

Titan 840 Component Overview

Understanding the core elements of any complex machinery is essential for effective operation and maintenance. Each individual component plays a specific role in ensuring the system functions efficiently. A clear grasp of these components allows users to address potential issues, perform routine checks, and execute repairs when necessary.

The mechanical structure consists of various interconnected sections, each designed to support specific functions. From power generation to movement, every element is built with precision to work harmoniously with the rest. By familiarizing yourself with the layout and role of each section, you can troubleshoot problems quickly and optimize performance.

This section focuses on the key components that make up the system, offering insight into their construction and relationship with one another. With this knowledge, users can more confidently navigate the machine’s workings, ensuring longevity and efficiency in operation.

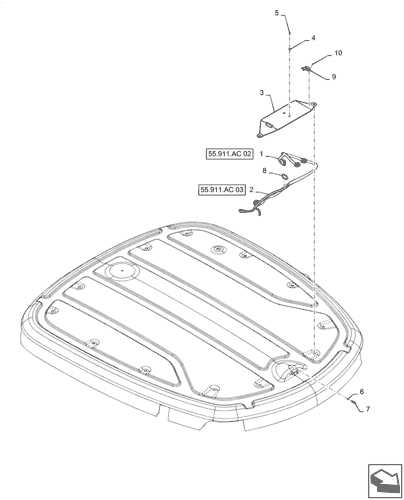

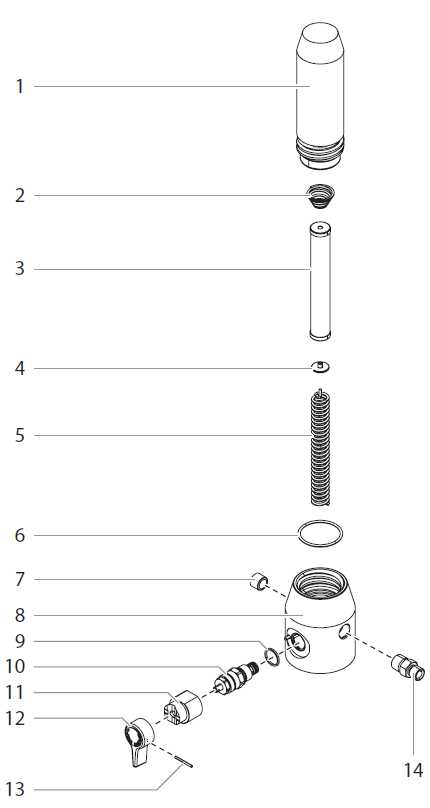

Understanding the Titan 840 Parts Layout

Familiarizing oneself with the internal configuration of a machine is crucial for proper use and maintenance. A well-organized layout helps users identify each individual component and understand how they interact with one another. This knowledge is essential for ensuring that the system runs smoothly and efficiently.

When studying the layout, it’s important to consider the relationships between different sections. Each part is strategically placed to support the overall function of the machine. By breaking down the structure, users can identify which areas to focus on during inspections or repairs.

Key Areas of Focus

- Power Mechanisms: The primary elements responsible for generating and distributing energy throughout the system.

- Movement Components: Parts that allow the machine to function and perform tasks, including gears and actuators.

- Control Systems: Elements that regulate performance and ensure smooth operation during use.

Benefits of Knowing the Layout

- Improved troubleshooting and maintenance processes.

- Quicker identification of damaged or worn-out components.

- Enhanced overall machine longevity and reliability.

By fully understanding the layout and how the pieces work together, users are equipped to handle maintenance tasks effectively, preventing issues before they arise and ensuring long-term performance.

How to Use the Titan 840 Diagram

Utilizing a visual representation of a machine’s internal structure is an essential skill for effective maintenance and troubleshooting. Such a guide enables users to quickly locate and identify each individual component, helping them understand how parts fit together and interact. This process simplifies repairs and ensures a more efficient workflow when dealing with issues or performing routine inspections.

To make the most out of the guide, it is crucial to approach it methodically. Start by familiarizing yourself with the layout to understand the overall flow of the system. Once you have a basic understanding, focus on specific areas that need attention or maintenance. Pay close attention to markings or symbols that highlight particular sections, as they often indicate important details related to functionality or repair needs.

Steps to Follow

- Identify the Sections: Begin by understanding the main areas of the machine and their function, such as power sources, control mechanisms, and movement systems.

- Locate Specific Components: Use the guide to pinpoint individual elements, making sure to note any labels or identifiers that can help in distinguishing parts.

- Refer to Maintenance Notes: Look for annotations or instructions that may provide valuable information about common issues or maintenance procedures.

- Follow a Logical Sequence: When performing repairs or checks, follow the sequence outlined in the guide to ensure no steps are missed.

By systematically using the guide, you’ll be able to troubleshoot issues with greater accuracy and perform repairs with minimal downtime. This approach leads to a more organized, efficient workflow and helps keep the machinery in optimal condition.