Maintaining machinery requires a clear understanding of its individual components. By identifying each part and how it functions, you can perform effective maintenance and ensure smooth operation over time. This section will guide you through the essential elements that make up these devices, offering tips for proper care and repair.

Essential Parts of the Device

Each machine consists of various elements that work together to achieve optimal performance. From the motor to the nozzle, each component has a specific role in the overall process. Recognizing the function of each part helps prevent malfunctions and promotes longevity.

Key Components

- Motor: Powers the device and drives the other functions.

- Control Knob: Regulates the flow and pressure of the material being used.

- Nozzle: Directs the flow of the material onto the surface.

- Filter: Keeps debris from clogging the system and ensures clean operation.

Identifying Issues and Troubleshooting

When problems arise, identifying the faulty component is essential for efficient repair. A clear understanding of each part’s function helps narrow down potential issues. Regular inspection is key to catching wear or damage early.

Maintenance Tips for Optimal Performance

Proper care ensures the equipment lasts longer and performs efficiently. Regularly cleaning each component and replacing worn-out parts can prevent major breakdowns. Follow these maintenance tips to keep your device in top condition:

- Clean all components after each use.

- Check the motor and filter regularly for signs of wear.

- Store the machine in a dry, safe place to avoid unnecessary damage.

- Replace worn-out components promptly to maintain performance.

By understanding the function and upkeep of each element, you ensure your equipment operates at its best for years to come.

Overview of Equipment Functionality

Understanding Key Elements of Models

How to Read Diagrams for Devices

Steps to Identify Components Precisely

Maintenance Tips for Longevity

Proper operation of any machinery relies on a deep understanding of its internal structure. Recognizing each element and its role ensures better performance and easier troubleshooting. This section provides an overview of essential parts, the process of identifying components, and tips for extending the lifespan of your device.

Understanding Key Elements of Models

Every machine has several components that work in harmony to deliver optimal performance. These parts, though varied, are crucial to the functionality of the whole system. A clear understanding of these parts and how they interact makes it easier to keep the equipment running smoothly and resolve any issues that arise.

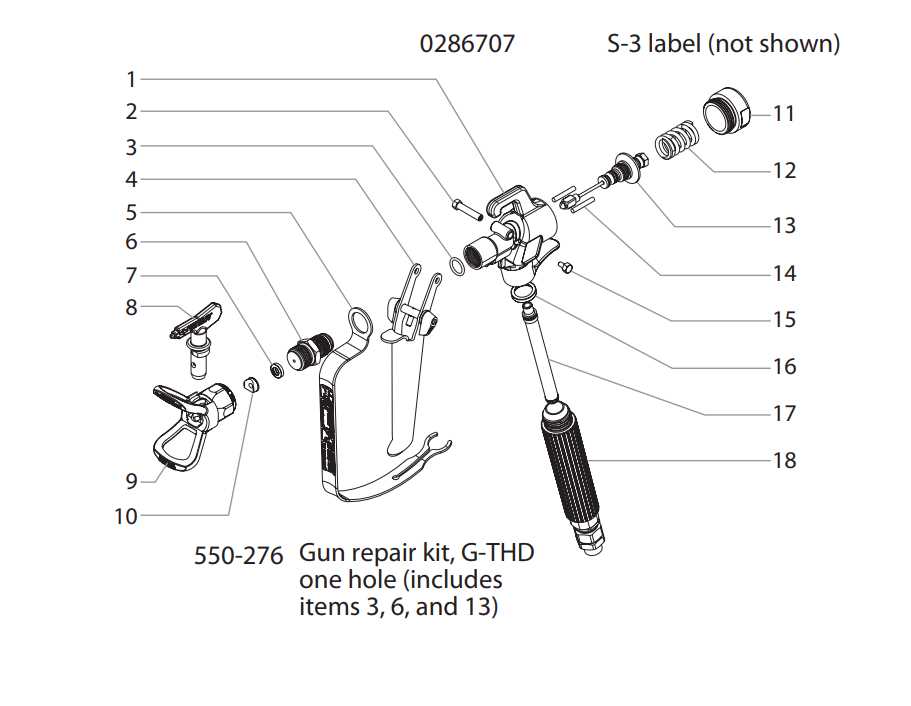

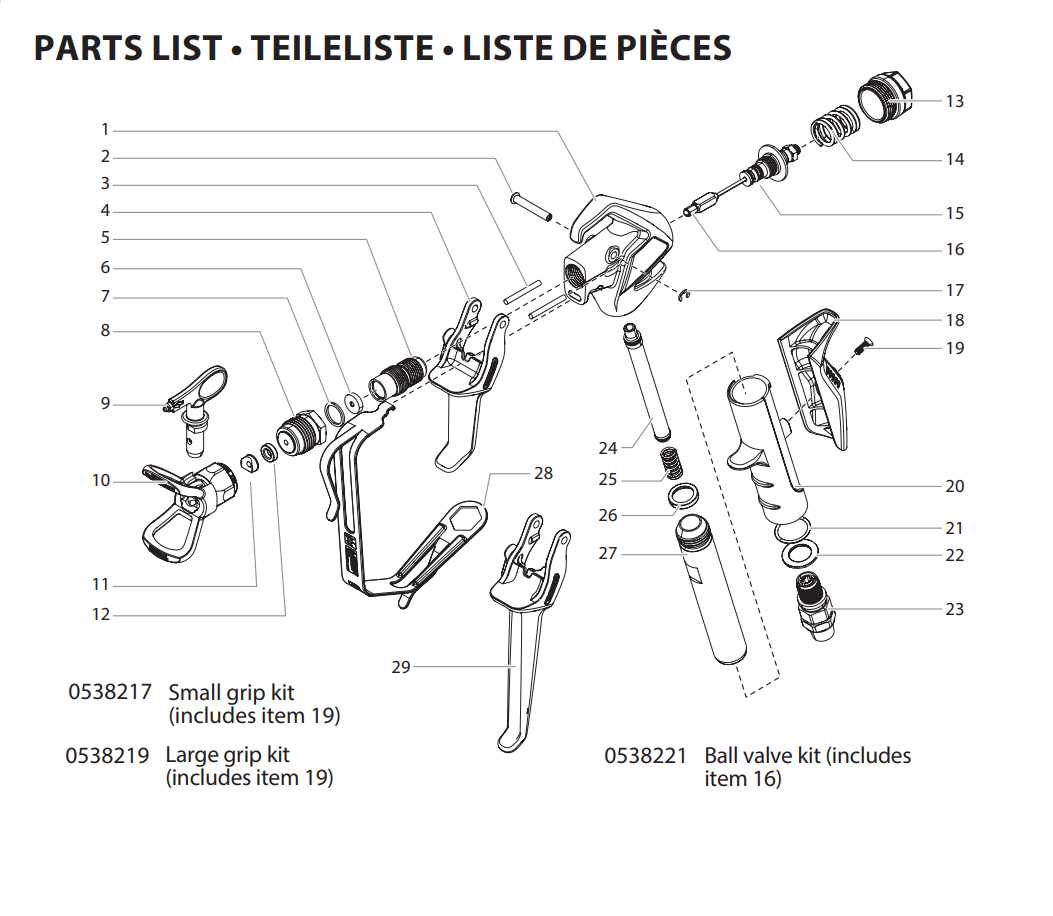

How to Read Diagrams for Devices

Diagrams serve as detailed representations of a device’s structure. Learning how to interpret these visuals helps you recognize where each element fits within the system. Understanding these diagrams allows for more precise identification of faulty components and aids in faster repairs.

Steps to Identify Components Precisely

Identifying components accurately requires a methodical approach. Begin by familiarizing yourself with the overall structure of the device. Once you know the layout, each part can be traced back to its specific function. Regularly inspecting your equipment helps spot potential issues early and ensures that each component is working as it should.

Maintenance Tips for Longevity

Maintaining your equipment properly is key to extending its life. Regular cleaning, checking for wear, and timely replacement of worn parts can prevent major breakdowns. Ensure that all components are properly lubricated and free from debris to maintain consistent performance. Following these simple maintenance steps helps your device operate efficiently for years to come.