Maintaining outdoor machinery requires a clear understanding of its internal components. Knowing how different parts function together ensures smooth operation and reduces the need for frequent repairs. Whether you’re a professional or a casual user, familiarizing yourself with the layout of essential elements helps you identify issues quickly and efficiently.

For effective maintenance, it’s crucial to have access to visual guides that detail how the various pieces fit together. These guides serve as invaluable tools for troubleshooting, making repairs, and performing routine maintenance tasks. By following a clear breakdown, you can keep your equipment in optimal working condition.

Regular upkeep and quick part replacements are key to extending the lifespan of your machinery. Knowing exactly where each component fits allows you to address problems without delay and minimize downtime, ensuring long-term performance.

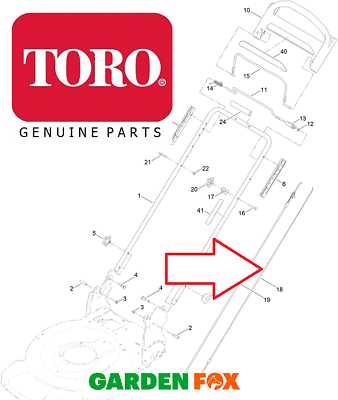

Toro 20333 Parts Overview

Understanding the key components of outdoor machinery is essential for efficient operation and easy troubleshooting. Each unit is made up of various elements that work together to ensure seamless functionality. Recognizing these components and their roles helps users manage maintenance tasks effectively and avoid costly repairs.

Commonly, these machines are equipped with a range of interchangeable parts, from the motor assembly to smaller, detailed components. Each of these pieces plays a vital role in keeping the equipment performing at its best. Identifying the essential components can make repairs simpler and improve the overall efficiency of the machine.

Having a clear overview of all components is especially important when it comes to servicing the machine. Whether replacing worn-out pieces or performing preventive maintenance, a structured understanding of the layout and function of each element ensures smooth operation for years to come.

Identifying Key Components in Toro 20333

Recognizing the critical elements within machinery is crucial for effective maintenance and repairs. By understanding the function and location of each key component, users can diagnose issues quickly and ensure the longevity of their equipment. Each machine consists of various functional units that contribute to its overall performance, and identifying these components helps streamline any necessary interventions.

Essential Functional Units

Among the most important elements are the motor, transmission, and control mechanisms, which work in tandem to ensure smooth operation. These units require regular inspection to prevent wear and tear, which could result in performance loss or system failure. Being able to identify them easily allows for faster troubleshooting and component replacement.

Smaller Components and Their Roles

In addition to the major units, smaller components such as filters, belts, and switches also play significant roles in keeping the machine running efficiently. While these parts may seem less important, neglecting their upkeep can lead to larger issues. Familiarizing oneself with these smaller elements is just as crucial for the maintenance of the overall system.

How to Replace Toro 20333 Parts Efficiently

Replacing worn or damaged components can be a straightforward process when done methodically. Proper preparation and understanding of the replacement steps ensure a smooth and efficient fix. Knowing the exact components that need attention and the proper procedures will save both time and effort.

Preparation Steps

Before starting the replacement process, ensure you have the necessary tools and replacement components. It is important to follow these steps:

- Review the equipment’s manual for guidance on the parts to replace.

- Gather the required tools, including wrenches, screwdrivers, and gloves.

- Turn off the machine and disconnect it from any power sources.

- Organize the workspace for easy access to tools and replacement parts.

Efficient Replacement Process

Once you have prepared your tools and workspace, proceed with the following steps for an efficient replacement:

- Remove the damaged or worn component carefully, noting its placement.

- Install the new component, ensuring it fits properly into place.

- Tighten any screws, bolts, or fasteners as needed, making sure everything is secure.

- Test the equipment to ensure the new component works properly and the machine is running smoothly.

By following these steps, replacing components becomes a seamless task, minimizing downtime and keeping your equipment in optimal condition.