Maintaining and repairing lawn machinery can seem like a daunting task, but having access to clear visual guides for all components can make the process much simpler. A detailed map of each piece’s function and placement can save time and effort when troubleshooting or replacing parts. With the right resources, even complex repairs become manageable.

Knowing the layout of your machine’s components allows for faster diagnosis of issues, ensuring that you address the root causes rather than temporary fixes. These resources also provide an easy way to ensure that you have all necessary parts on hand before beginning any maintenance work.

For those unfamiliar with mechanical systems, understanding these guides can help build confidence in handling repairs. In addition, with the correct information, you can prevent common mistakes and avoid costly errors that might arise from improper assembly or disassembly.

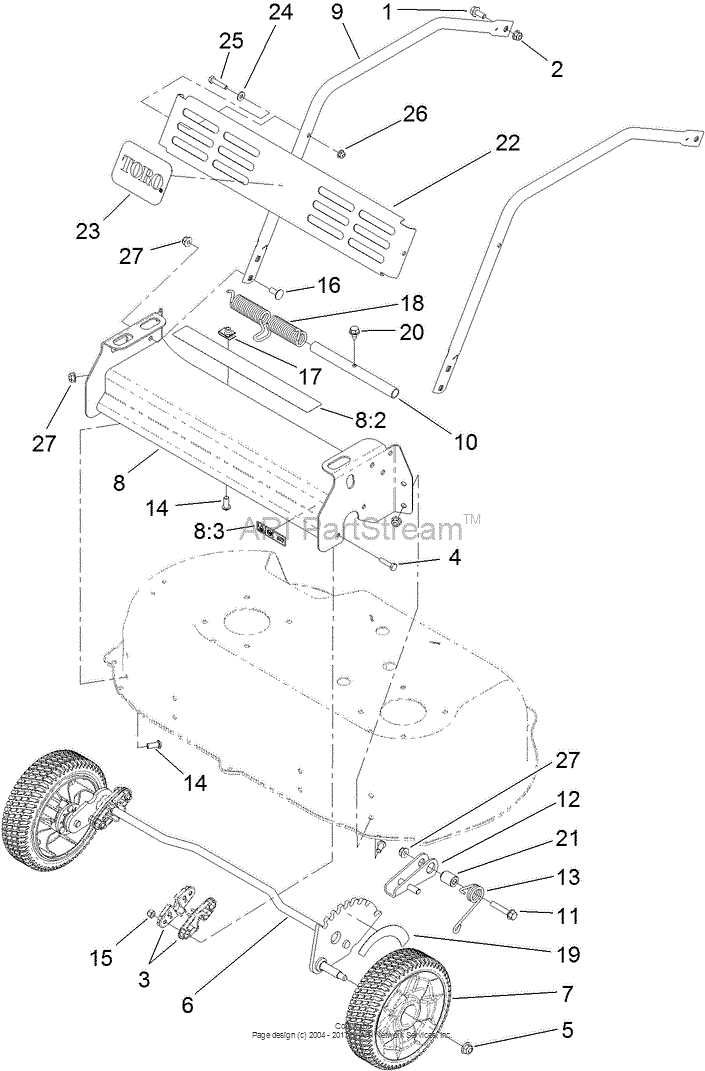

Toro 22200 Parts Breakdown

Understanding the individual components of your lawn equipment is essential for effective maintenance and repairs. Breaking down the entire system into smaller, more manageable parts allows for a clearer approach when addressing specific issues. Each element plays a vital role in the overall function, and identifying them correctly ensures a smoother repair process.

Component Identification

Each part serves a distinct function, from the main engine components to the smaller accessories that support them. When performing repairs, it is crucial to know exactly which component is malfunctioning. Labeling and mapping each part correctly helps avoid confusion and reduces the risk of errors during the assembly process.

Replacement and Repair Considerations

Knowing which parts to replace or fix is a critical aspect of maintaining the longevity of your equipment. Some components wear out over time and need to be replaced regularly, while others may require less frequent attention. Understanding the repair frequency and the lifespan of each part can save you time and money, as well as prevent further damage to your machine.

How to Read Toro 22200 Diagram

Interpreting visual guides of mechanical systems is crucial for effective maintenance and repair work. These guides are designed to clearly depict the layout and arrangement of various components, helping users understand how everything fits together. Knowing how to properly read such a schematic can simplify complex procedures and save time during troubleshooting.

Understanding the Key Elements

When examining a visual representation of your equipment, focus on the following key aspects:

- Component Labels: Each part is typically numbered or named for easy identification.

- Connection Points: Arrows and lines indicate how parts are connected or interact with one another.

- Part Dimensions: Sometimes the size or scale of parts is shown, giving a better sense of the overall structure.

Step-by-Step Guide to Reading the Diagram

To effectively read and use the visual guide:

- Start by identifying the overall layout of the equipment. This will give you a sense of how each section is arranged.

- Look for the specific part you’re interested in and trace its connections to other components.

- Cross-reference the numbers or labels in the diagram with the equipment manual for further details.

- If applicable, check the part’s location in the assembly to see how it integrates with other parts for proper function.

Common Issues with Toro 22200 Parts

Over time, mechanical systems can experience various issues due to wear and tear on individual components. Understanding the common problems associated with these elements can help users quickly identify and resolve malfunctions. By recognizing these frequent issues, you can avoid unnecessary repairs and maintain the equipment’s efficiency.

Worn Out Components

One of the most common issues that arises is the deterioration of certain components due to prolonged use. Parts such as belts, filters, and seals may lose their effectiveness, resulting in poor performance or even complete failure. Regular inspections and timely replacements can prevent these failures from affecting the overall system.

Incorrect Assembly or Alignment

Improper installation or misalignment of parts is another frequent problem that can arise. If components are not aligned correctly, it can lead to mechanical strain, which could cause further damage to surrounding elements. Ensuring proper alignment during assembly is essential to maintaining the machine’s functionality.