Maintaining heavy machinery is crucial for ensuring smooth operations and extending the lifespan of your equipment. Proper knowledge of the internal components and their functions can make all the difference when it comes to preventing issues and reducing downtime. In this guide, we will explore the key elements of understanding your machine’s structure and how you can keep everything running efficiently.

Understanding the various components is vital for recognizing potential problems early on. By learning how each part fits into the larger system, you can troubleshoot issues effectively, perform regular upkeep, and identify the right replacements when necessary.

Knowing where to find the right details will empower you to take action quickly, whether it’s for repairs or upgrades. This information is invaluable for both professionals and enthusiasts who want to maintain their equipment in top condition without unnecessary delays or costs.

Understanding Toro Dingo Parts

Every machine consists of a variety of components that work together to achieve optimal performance. Familiarizing yourself with the different elements of your equipment allows for efficient maintenance and quick identification of potential issues. Whether you’re an operator or technician, understanding the basic structure and function of each piece is essential for keeping everything in working order.

In any mechanical system, each component has a specific role. From the engine to the wheels, each part contributes to the overall functionality. By studying how each piece interacts, you can easily troubleshoot problems, perform routine checks, and ensure that the machine operates as intended for years to come.

Moreover, having access to detailed documentation or visual guides can simplify the process of identifying and replacing faulty components. This knowledge ensures that you are able to make informed decisions when it comes to repairs or upgrades, saving both time and resources in the long run.

How to Read the Parts Diagram

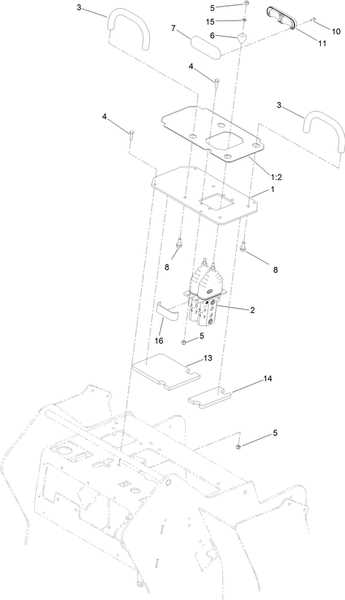

Understanding visual representations of your machine’s components is crucial for identifying the location and function of each part. These illustrations provide clear insights into how various pieces fit together, helping you efficiently troubleshoot and perform maintenance tasks. Learning to read these guides is an essential skill for anyone looking to keep their equipment running smoothly.

To make the most of these resources, start by familiarizing yourself with the key symbols and labels. Each section typically includes detailed annotations that describe the part number, name, and sometimes its specifications. By carefully following the lines and labels, you can trace the flow and connections between the components.

| Symbol | Description |

|---|---|

| 1 | Engine |

| 2 | Hydraulic Pump |

| 3 | Drive Belt |

| 4 | Wheel Assembly |

| 5 | Fuel Tank |

By practicing with these guides and becoming familiar with the symbols, you will be able to locate and identify components faster, making repairs and maintenance tasks much easier and more efficient.

Common Equipment Maintenance Tips

Regular upkeep of your machinery is vital for ensuring long-term performance and minimizing downtime. By following a set of proven maintenance practices, you can avoid costly repairs and keep the system running smoothly. In this section, we highlight key maintenance tasks that should be performed routinely to ensure everything stays in optimal condition.

Routine Cleaning and Inspection

One of the simplest yet most effective ways to maintain equipment is through regular cleaning and inspection. This helps identify potential issues early and prevents the build-up of debris that can impair function. Some basic steps include:

- Clean the engine and other parts to remove dirt and grease.

- Inspect the belts, hoses, and filters for signs of wear or damage.

- Check for leaks or unusual sounds that could indicate problems.

Regular Lubrication and Fluid Checks

Lubricating moving parts and checking fluid levels are essential tasks for preventing premature wear and tear. Inadequate lubrication can cause friction, leading to part failure. Follow these steps to ensure proper care:

- Lubricate joints, bearings, and pivot points as recommended by the manufacturer.

- Check and replace engine oil and hydraulic fluid regularly.

- Ensure that fuel filters are clean and free of blockages.

By adhering to these maintenance tips, you can extend the lifespan of your machine, improve its efficiency, and reduce the likelihood of unexpected breakdowns.

Essential Components for Optimal Performance

For any machine to function at its best, certain elements must work in harmony. Each key component plays a specific role in ensuring smooth operation, and when one part fails or underperforms, it can affect the entire system. Understanding the vital parts of your equipment is crucial to maintaining its efficiency and reliability.

Among the most critical components are the engine, hydraulic system, and drive mechanism. These systems provide the necessary power, control, and movement, making them fundamental for any machine’s functionality. Regular monitoring and maintenance of these elements will help keep the equipment running at peak capacity.

Additionally, the fuel and electrical systems are equally important. Proper fuel management ensures consistent performance, while the electrical components control essential functions, from ignition to lighting. Ensuring that these systems are in good condition will maximize the lifespan and efficiency of the equipment.

Finding Replacement Components

When it comes time to replace a faulty or worn-out component, finding the right replacement is key to restoring your machine to optimal performance. The process of sourcing new parts involves not only identifying the correct pieces but also ensuring their compatibility with your equipment. Having access to reliable sources for these components can save time and prevent delays in repairs.

Authorized dealers are often the most dependable places to acquire replacements, as they offer parts that are specifically designed for your model. Many manufacturers provide online catalogs or databases, allowing you to search by serial number, component name, or type, helping you pinpoint the exact piece you need.

Additionally, third-party suppliers may offer compatible alternatives that can be more cost-effective. However, it is important to check for quality guarantees and reviews to ensure that these replacements will perform as expected without compromising the functionality of your machine.