When it comes to maintaining outdoor machinery, knowing how each component fits together and functions is essential for smooth operation and long-term durability. Being able to identify and understand the key elements of your equipment can save both time and money when repairs or replacements are needed. This guide will help you navigate the crucial components of your machine and provide insights into keeping it in peak condition.

Having a visual reference can be a game-changer, whether you’re looking to troubleshoot an issue or replace a worn-out piece. With the right knowledge, you can handle basic maintenance tasks independently. Familiarizing yourself with the layout and structure of the system will ensure you’re not caught off guard when problems arise.

Efficient repairs require more than just the right tools; understanding the mechanics at play is key. With this knowledge, you’ll gain the confidence to tackle issues head-on and ensure the equipment performs effectively throughout its lifespan.

Understanding Toro Snow Thrower Parts

To ensure that your outdoor machinery works efficiently, it’s important to grasp the function and design of each individual component. A thorough understanding of the core mechanisms allows you to better assess issues and take the necessary steps to maintain or repair the unit. Each element plays a specific role in the overall operation, contributing to the seamless performance of the entire system.

Key components typically include moving parts, motors, and control systems, all of which must interact smoothly. Identifying the function of each section will help you recognize where a problem might be occurring and what needs to be replaced or fixed. Familiarity with how these elements fit together is essential for making informed decisions when handling repairs.

Comprehending the inner workings of your equipment not only helps with fixing problems but also enables you to conduct regular maintenance. This proactive approach ensures that the machine remains operational for a longer period, reducing the frequency of costly repairs. Understanding what each part does gives you a clearer view of when and how to perform upkeep to prevent more serious issues down the road.

How to Read Toro Parts Diagrams

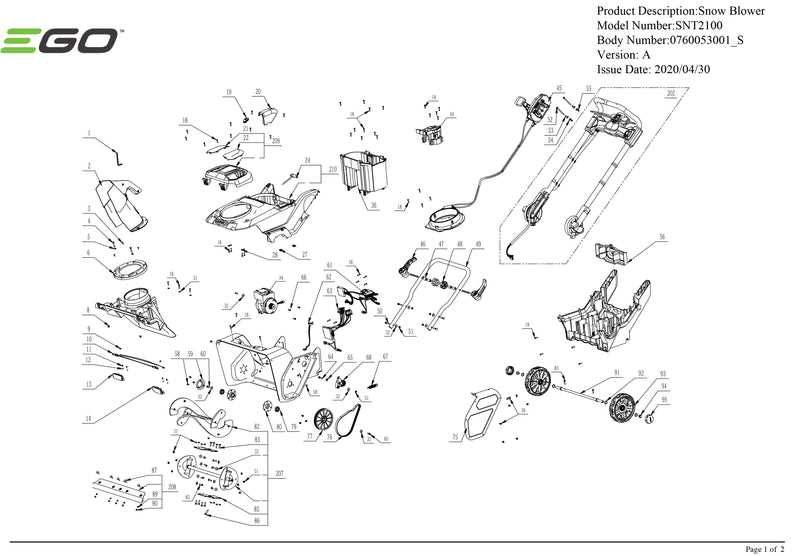

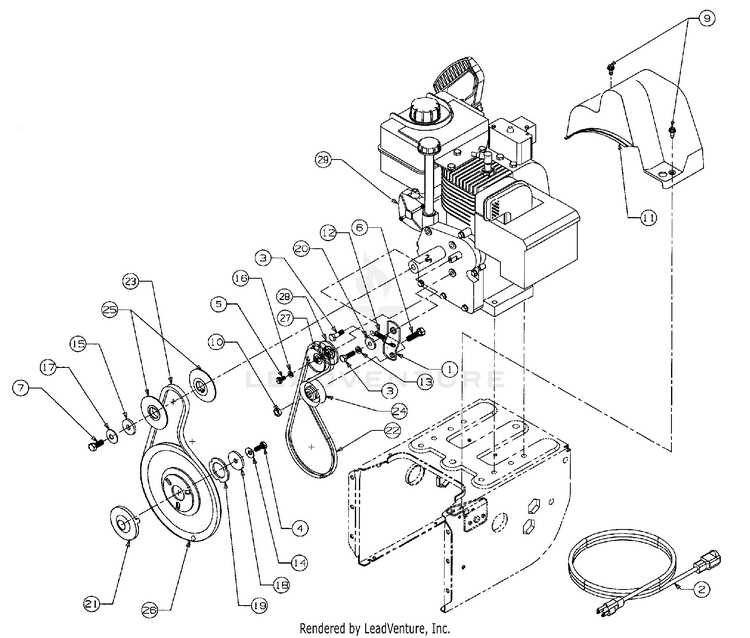

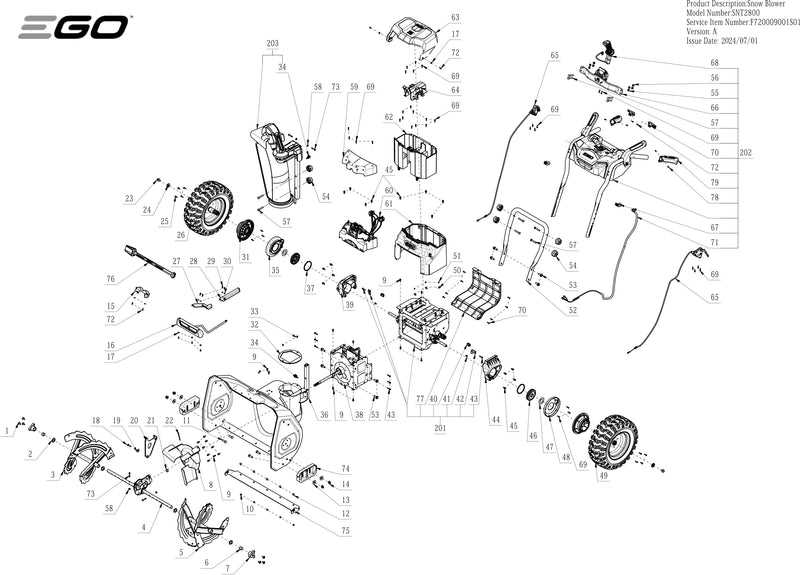

Understanding visual references is a crucial step in accurately identifying and locating the components within your equipment. These illustrations are designed to provide clarity by showing how each part is positioned and how it interacts with the rest of the system. By properly interpreting these visuals, you can efficiently navigate through repair or maintenance tasks.

Key symbols and labels are typically used to indicate specific components, their numbers, and sometimes the materials or specifications. Familiarizing yourself with the legend or key that accompanies these drawings can help you avoid confusion when looking for a particular item. This understanding simplifies the process of locating and ordering the correct replacements or performing the right adjustments.

Step-by-step reading involves following the flow of the diagram, starting from the primary unit and tracing each individual part as it connects to others. This method ensures you don’t miss any important details and can troubleshoot with confidence. Mastering this technique allows you to not only repair but also maintain your equipment with a higher level of expertise.

Common Toro Snow Thrower Repairs

Over time, outdoor machinery can experience wear and tear that affects its overall functionality. Common issues often involve components that are subjected to constant movement, heavy use, or exposure to harsh conditions. Addressing these problems quickly can prevent further damage and ensure the equipment remains efficient during its operation.

Motor and Drive System Issues

One of the most frequent problems is related to the motor and drive mechanisms. These components can wear down due to overuse, causing the machine to lose power or stop functioning altogether. Regular inspection of belts, gears, and the motor itself can help identify potential issues before they become major failures.

Worn or Broken Auger Blades

Another common repair involves the auger blades, which can become damaged or dull over time. This affects the machine’s ability to move material efficiently. Replacing or sharpening the blades is an essential part of regular maintenance to keep the equipment operating at peak performance.