Maintaining outdoor machinery requires a clear understanding of its structure and key elements. For efficient repairs and upkeep, it’s essential to have access to detailed visual guides that outline the various components of your equipment. These references are designed to simplify the identification of parts and ensure smooth maintenance procedures.

By consulting these resources, users can easily identify individual components, their functions, and potential issues that may arise. This knowledge helps streamline the repair process and reduces downtime, enabling better performance and longevity of the machine.

Whether you’re a professional or a hobbyist, having a comprehensive map of your equipment’s inner workings will help you tackle repairs with confidence. A clear visual guide not only saves time but also enhances your overall understanding of how the different pieces fit together and interact.

Toro SS5000 Parts Breakdown

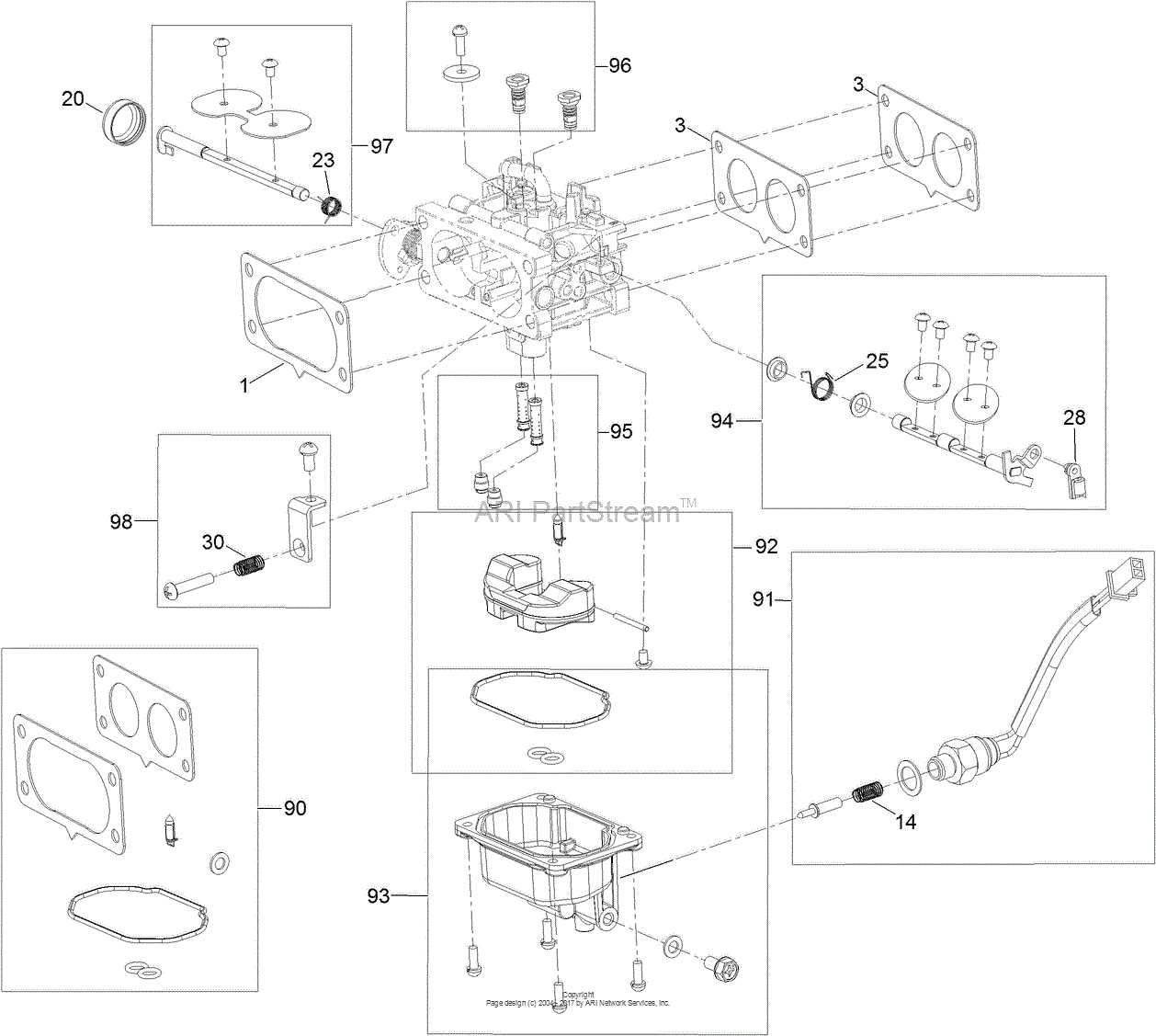

Understanding the individual components of your equipment is crucial for effective maintenance. Each element of a machine plays a specific role in ensuring smooth operation. Identifying these components allows for timely repairs and better decision-making when dealing with malfunctioning parts. This section offers a detailed breakdown of the various sections and their corresponding pieces, helping you to navigate the machinery more efficiently.

Key Components and Their Functions

Every piece within the machine serves a vital purpose. From the engine and transmission to smaller attachments, each part contributes to the overall performance. By familiarizing yourself with these components, you can identify potential weak points or worn-out parts before they cause larger issues. This proactive approach minimizes downtime and maximizes the machine’s efficiency.

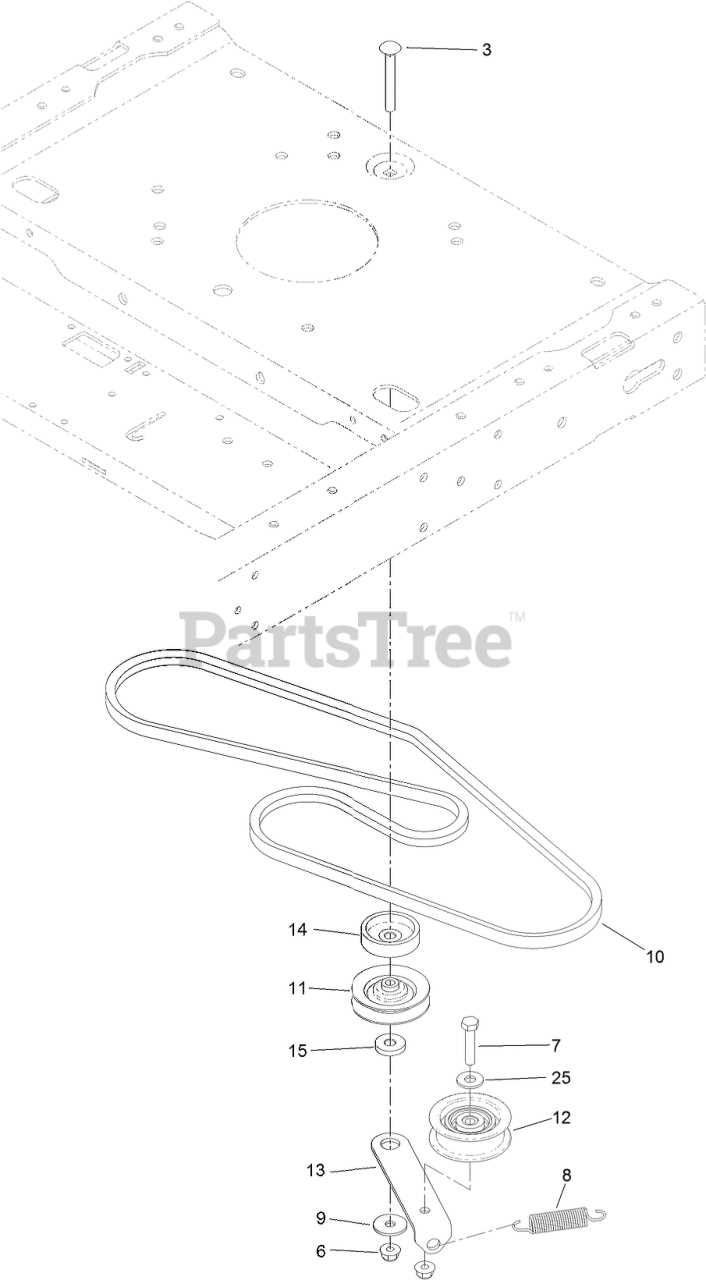

Commonly Replaced Parts

Some elements of the equipment are more likely to wear out over time and require frequent replacements. These parts include belts, filters, and spark plugs. Knowing where these components are located and how to access them is essential for quick repairs. Regular inspections and timely replacements ensure that the machine continues to run smoothly and reliably for years.

Understanding Toro SS5000 Component Layout

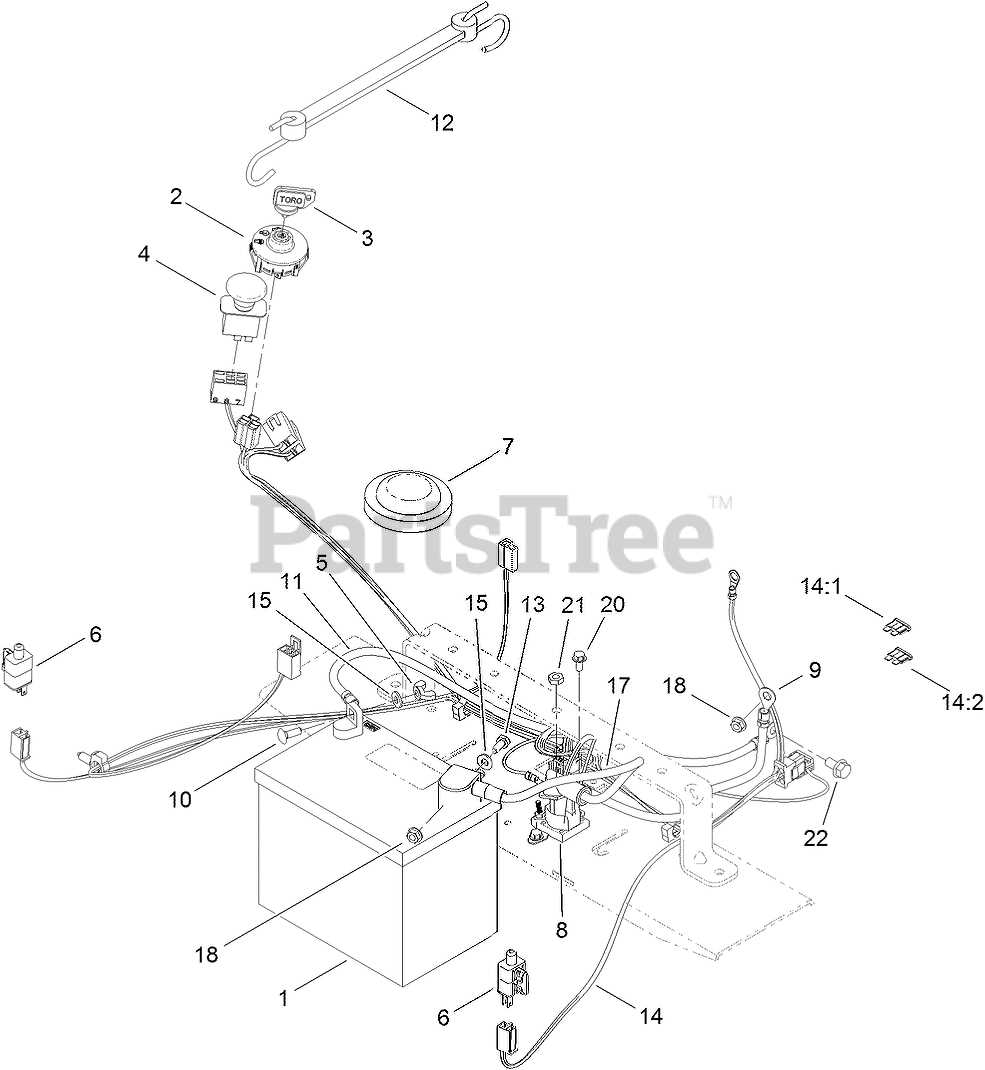

Having a clear understanding of the arrangement and positioning of each part within a machine is vital for efficient troubleshooting and repairs. Knowing where each component is located and how it interacts with others ensures that any issues can be addressed quickly. This section focuses on the layout of various sections and components, helping you identify their placement and function with ease.

Overall System Organization

Each section of the equipment is carefully designed to work in harmony with the others. The organization of the engine, transmission, and other crucial systems allows for maximum efficiency. By studying the system layout, you gain insight into how the different parts support one another, ensuring smooth operation of the entire machine.

Critical Areas to Examine

Some areas of the machine require more attention due to their complexity or vulnerability to wear and tear. Identifying these critical zones and their corresponding components allows for more focused maintenance. A thorough understanding of these areas helps prevent serious malfunctions and prolongs the machine’s lifespan.

How to Use the Toro SS5000 Diagram

Using a detailed visual guide is essential for effective maintenance and repair tasks. These resources help you navigate the various components of a machine, allowing you to identify, inspect, and replace parts with ease. Understanding how to read and interpret these guides is key to ensuring efficient repairs and reducing downtime.

To start, focus on the layout and organization of the guide. It typically categorizes components based on their location and function within the machine. By identifying each part’s position, you can quickly locate and address any areas requiring attention. Take note of the labels and numbers associated with each part, as these will assist in finding the correct replacement pieces or troubleshooting issues.

Once you are familiar with the general structure of the guide, use it to pinpoint potential problems. Whether you’re addressing worn-out parts or conducting routine maintenance, these diagrams provide the clarity needed to make informed decisions. With regular use, you’ll gain a deeper understanding of your equipment’s mechanics and improve your overall repair efficiency.