Effective operation of a mechanical lifting or pulling device relies on understanding the individual elements that make up the system. Each component plays a vital role in ensuring smooth and reliable performance, whether in recreational or professional settings. Recognizing the parts and their function is key to maintaining and troubleshooting the equipment efficiently.

By exploring a detailed representation of these elements, users can gain a clearer insight into the structure and mechanics of their device. Such knowledge not only aids in quick identification of any malfunctioning parts but also ensures a longer lifespan of the system.

Proper maintenance and careful inspection are crucial in avoiding common issues and optimizing performance. Understanding how everything fits together empowers users to take the necessary steps in preserving their equipment.

Understanding Traveller Winch Components

In any mechanical system designed for lifting or pulling heavy loads, every individual element plays a crucial role in the overall performance. These systems consist of various interconnected components that work together to achieve smooth functionality. A clear understanding of these parts helps users maintain, repair, and troubleshoot their equipment effectively.

Each piece, from the motor to the control mechanisms, is designed to perform a specific function. Recognizing the role of each part allows operators to identify issues quickly and take appropriate action. Moreover, familiarizing oneself with the system’s layout helps in ensuring that each component is functioning optimally and that the equipment remains in peak condition.

Proper maintenance and regular inspection of each element are essential for preventing wear and tear. Understanding how all components interact makes it easier to diagnose problems early, improving both the safety and longevity of the system.

How to Read a Winch Parts Diagram

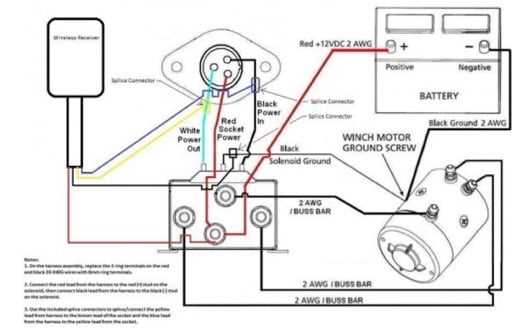

Interpreting technical schematics for mechanical systems can seem complex, but with the right approach, it becomes an invaluable tool for understanding the structure and functionality of each component. A well-labeled visual representation serves as a guide to identifying parts, their arrangement, and how they interact with each other within the overall setup.

Identifying Components and Symbols

One of the first steps in understanding a schematic is recognizing the various symbols and labels used to represent each part. These symbols are often standardized, allowing for easier interpretation across different systems. By familiarizing yourself with the common shapes and notations, you can quickly pinpoint the individual elements and comprehend their purpose in the mechanism.

Following the Flow and Connections

After identifying the components, the next step is understanding how they are connected. Diagrams usually display lines or arrows that represent connections between parts, showing the flow of energy or movement within the system. This is crucial for diagnosing issues or planning maintenance, as it reveals how each part affects the others when in operation.

Common Issues with Traveller Winch Parts

Mechanical systems designed for heavy-duty lifting and pulling are subject to wear and tear over time, leading to various issues with their components. Understanding the most common problems can help users identify and address them before they become serious. Regular maintenance and careful observation are key to extending the lifespan of these systems and ensuring their optimal operation.

Electrical Failures and Malfunctions

One of the most common issues in mechanical systems is electrical failure. This can be caused by damaged wiring, faulty switches, or a malfunctioning motor. When electrical connections fail, the entire system may stop working or operate intermittently. Regularly checking the wiring and ensuring proper connections can help prevent such problems.

Mechanical Wear and Tear

Another frequent issue is the wear of moving parts such as gears, drums, or cables. Over time, constant use can lead to parts becoming loose, misaligned, or worn out. This may result in inefficient operation or even a complete breakdown. Regular lubrication and timely replacement of worn components are essential in preventing these issues from affecting performance.