Maintaining outdoor machinery often requires a clear understanding of its individual components. Whether you’re repairing, replacing, or upgrading, knowing how each part interacts is essential for smooth operation. This guide will walk you through an organized approach to visualizing these elements, making it easier for you to perform necessary maintenance.

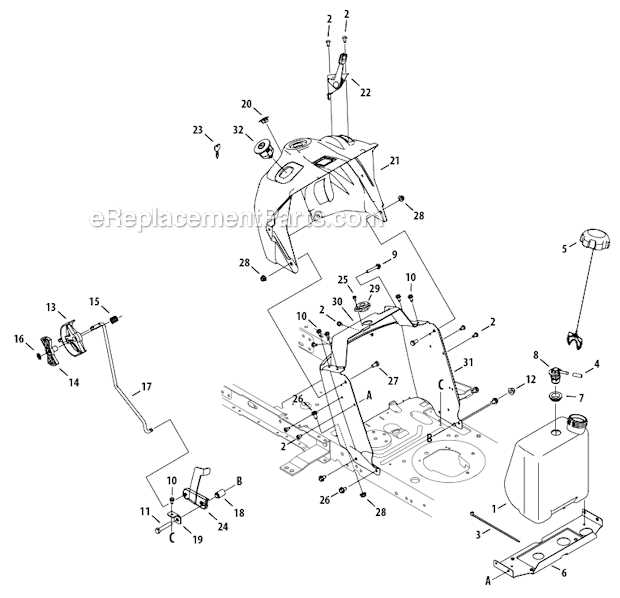

By reviewing an organized schematic, you can identify the crucial elements that keep the equipment running efficiently. These illustrations serve as a valuable tool for anyone looking to troubleshoot issues, ensure proper assembly, or find specific replacements. Knowing the layout and function of each section can save you time and effort when addressing any malfunctions.

Effective use of these visual references helps avoid mistakes and ensures you’re using the correct components. Proper understanding can prevent damage, improve efficiency, and extend the life of the equipment, making maintenance tasks less daunting.

Understanding the Equipment Layout

When maintaining any outdoor machinery, it’s essential to familiarize yourself with the layout of its components. A visual guide helps break down the structure, making it easier to identify each piece and understand its role in the overall function of the machine. This knowledge is invaluable when performing repairs or ensuring all parts are correctly assembled.

These detailed schematics are designed to show the placement and connection of various elements, offering clarity on how each part fits within the system. By studying these references, you can effectively troubleshoot issues, spot worn-out components, and make informed decisions about replacements and repairs.

Understanding the configuration also allows for more efficient maintenance, reducing the likelihood of errors. Whether you’re a first-time user or an experienced technician, having a clear visual representation ensures you can navigate the assembly process with confidence and ease.

Identifying Key Components of the Model

To efficiently operate and maintain any machine, recognizing its core components is crucial. Understanding how different sections interact and where they are located within the system is the first step toward ensuring smooth performance. Key elements not only contribute to the machine’s functionality but also help in troubleshooting and repair processes.

Main Mechanical Elements

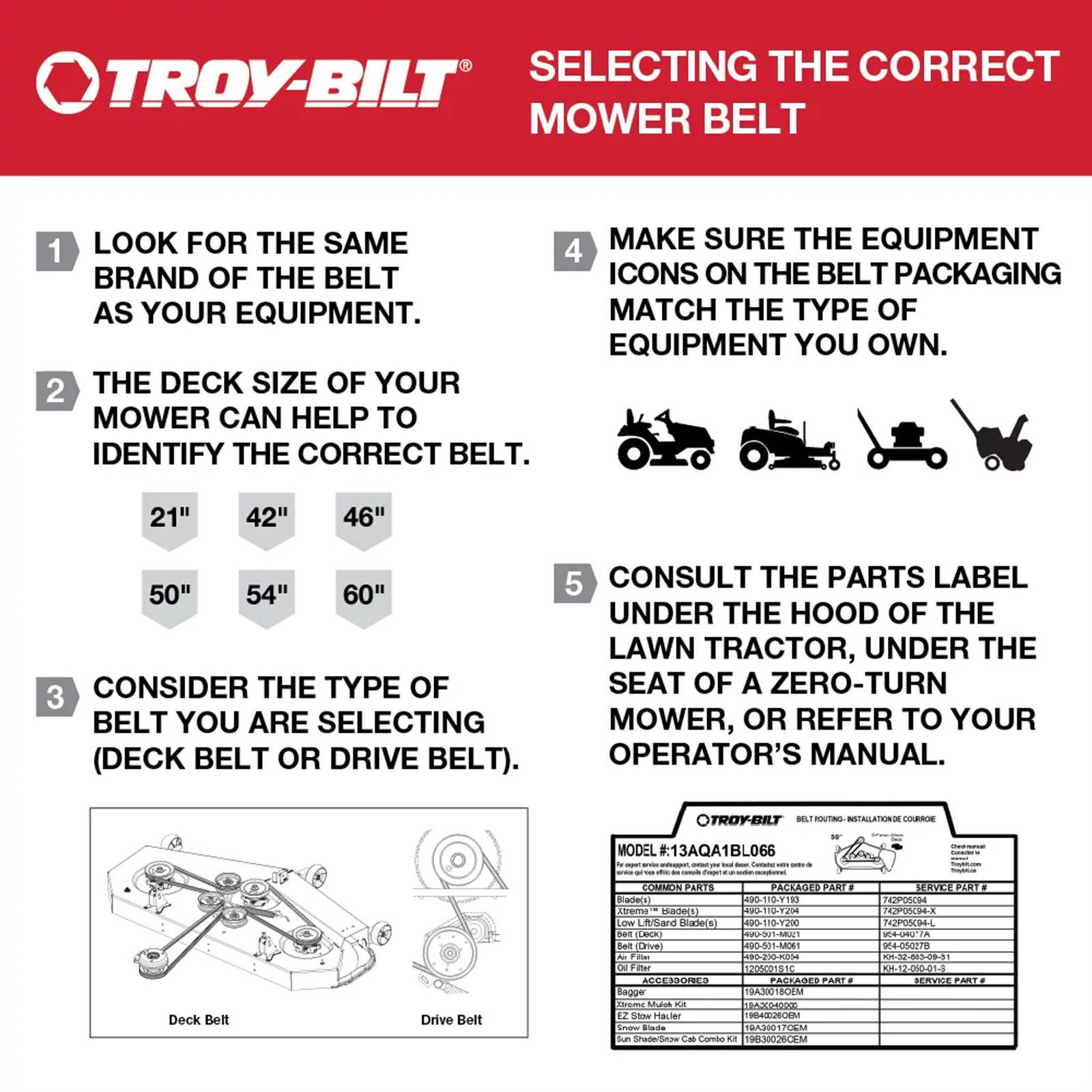

The mechanical parts form the backbone of the equipment, including engines, belts, and other vital structures. These components are directly responsible for the movement and power distribution within the device. Knowing the specific location and function of each mechanical part allows for easier identification during maintenance or when seeking replacements.

Supporting Functional Units

Supporting units, such as electrical connections, filters, and levers, play a significant role in the proper functioning of the machine. Though less visible, they ensure that the system runs efficiently and safely. Recognizing these supporting elements is just as important as understanding the main mechanical components.

How to Use the Schematic Effectively

Using a visual representation of your machine’s layout can greatly enhance the ease of identifying issues and locating specific components. This tool allows you to see how different elements are arranged, making repairs and maintenance tasks more manageable. With the right approach, these guides provide a clear path to efficient troubleshooting and part replacement.

Step-by-Step Guide

To make the most of the schematic, follow these steps:

- Start with the overview: Get familiar with the entire layout before focusing on individual parts. Understanding the general structure will help you locate specific components faster.

- Focus on one section at a time: Break down the diagram into smaller segments. This allows you to concentrate on one area, minimizing confusion and avoiding mistakes.

- Identify part numbers: Make sure to note down any specific identifiers for the parts you need to replace or inspect. These references will help you order replacements more efficiently.

- Cross-reference with your equipment: Match the diagram with your actual machine to verify that the components are in their correct positions.

Tips for Efficient Use

- Keep a checklist: As you go through the schematic, create a checklist to ensure every component is checked and confirmed.

- Use magnification: For more intricate parts, zoom in on sections for a closer look to avoid missing smaller elements.

- Consult experts if needed: If something seems unclear, don’t hesitate to ask for guidance from a professional or consult additional resources.