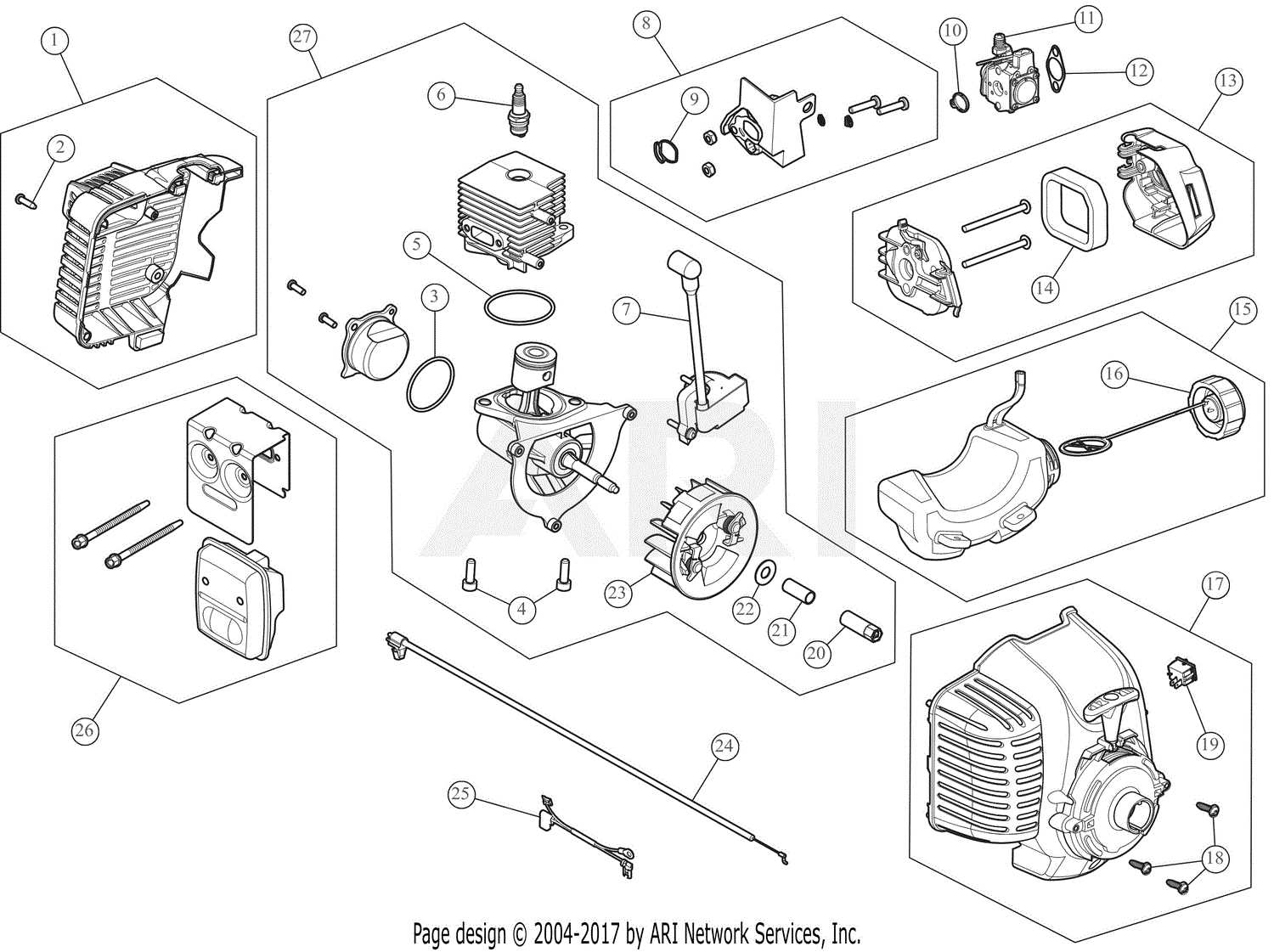

When it comes to maintaining outdoor equipment, having a clear understanding of its internal structure is crucial. Knowing the various components and how they interact can help prevent potential issues and ensure smooth operation. Proper maintenance begins with familiarity, and this can be achieved by exploring the layout and arrangement of essential elements within the machine.

Familiarizing yourself with the internal workings of your snow blower will make repairs and upkeep tasks easier. Each part plays a unique role, contributing to the overall performance. With a detailed view of the system, identifying wear and tear or misalignment becomes simpler, enabling you to take timely action.

Comprehending this essential knowledge not only improves efficiency but also extends the longevity of the equipment. A well-maintained machine is more reliable and operates optimally throughout its lifespan. This guide will help you gain valuable insights into the key components of your snow blower.

Understanding the Components of Your Snow Blower

Every snow removal machine consists of multiple interrelated elements, each contributing to its overall performance. Understanding how these components work together is vital for effective operation and maintenance. From the engine to the auger system, each section plays a specific role in ensuring that the machine performs its job efficiently.

One of the key components is the engine, which powers the entire unit. It is responsible for generating the necessary force to drive the augers and propel the snow blower forward. Other important parts include the chute control system, which directs the snow, and the wheels or tracks that provide stability and mobility across different surfaces.

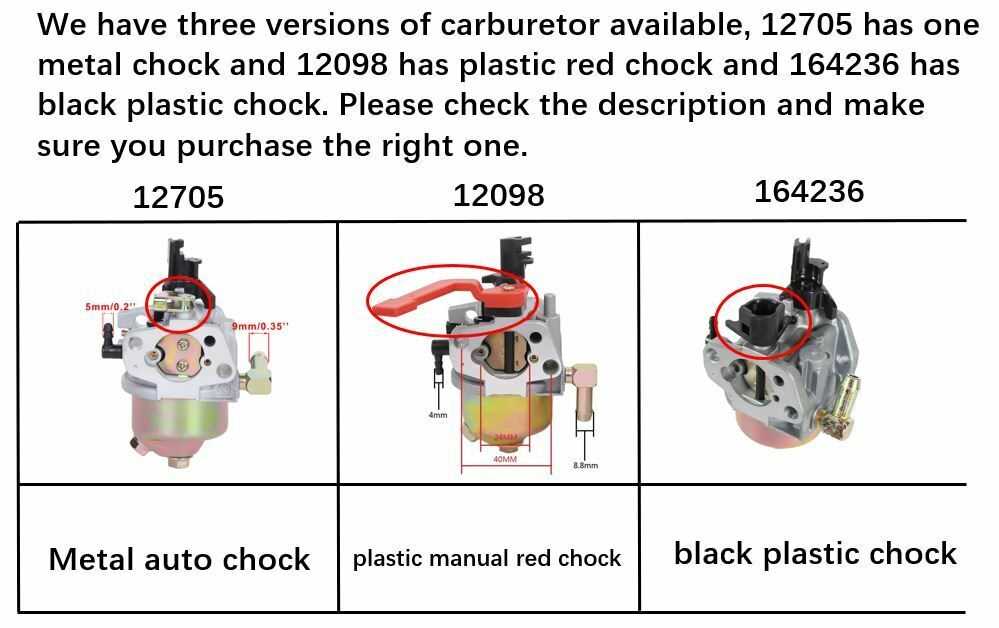

Familiarity with these components not only helps in identifying potential issues but also guides in selecting the right tools and replacement parts when needed. Understanding the layout ensures that you are well-equipped to handle routine maintenance and troubleshooting, ultimately prolonging the life of your machine.

How to Identify Essential Parts

When maintaining or repairing a snow removal machine, recognizing the crucial elements is the first step towards effective care. Knowing which components are vital for the machine’s functionality can prevent unnecessary replacements and help with quick repairs. A clear understanding of these core sections ensures better troubleshooting and maintenance strategies.

Key Functional Components

Start by identifying the key operational parts such as the engine, auger system, and chute. The engine powers the unit, while the auger system breaks through the snow, and the chute directs the output. These are the primary components that ensure the snow blower operates efficiently.

Supportive Elements

Other supportive elements, like the control systems for speed and direction, as well as the frame and wheels, are essential for providing stability and maneuverability. While they don’t directly affect performance, they are necessary for smooth and safe operation.

Identifying and understanding these elements allows for proper diagnostics and ensures that maintenance is focused on the most important areas. Regular inspection of these components keeps your machine running at its best.

Maintaining Your Snow Blower with Accurate Diagrams

Proper maintenance of your snow clearing equipment is essential to ensure it runs efficiently throughout the winter season. Having a visual representation of the machine’s structure and components can be incredibly useful when performing routine checks or repairs. With clear diagrams, identifying worn-out parts and understanding assembly becomes much easier, helping to extend the lifespan of the unit.

Importance of Visual References

Accurate illustrations of your equipment allow you to pinpoint specific areas that require attention. Whether it’s the engine, auger system, or control mechanisms, a well-detailed guide will help you understand the placement and function of each element. This makes it easier to follow the correct maintenance procedures and avoid costly mistakes.

Performing Routine Maintenance

Regular upkeep, such as cleaning, lubricating, and checking for wear, can be done more efficiently when you have a precise view of the internal components. Knowing which parts are more susceptible to damage allows you to focus your efforts and prevent more severe problems from arising. Using a diagram as a reference ensures that every task is completed thoroughly.