Maintaining and repairing your garden machinery requires a solid understanding of its individual components and how they work together. Knowing the layout and function of each part ensures that you can troubleshoot and fix issues more efficiently, helping you get the most out of your equipment.

In this guide, we break down the essential parts of a popular gardening machine, explaining their roles and how to identify them. By gaining a clearer understanding of these elements, you’ll be better equipped to perform repairs and replace worn-out components with confidence.

Efficient upkeep depends on knowing what each part does and recognizing the signs of failure. With the right information, maintenance becomes less daunting, allowing you to keep your equipment in peak condition for years to come.

Understanding Garden Equipment Components

Every gardening machine is made up of a variety of interconnected components that work together to perform tasks efficiently. A clear understanding of these elements allows you to troubleshoot problems, carry out necessary repairs, and ensure the longevity of your equipment. Each piece plays a crucial role, from the engine to the attachments, and knowing how they interact will make maintenance much easier.

Key Components to Know

The primary parts of any garden cultivator include the engine, drive system, and digging mechanisms. The engine powers the entire unit, while the drive system transmits energy to the working parts. The digging blades or attachments are responsible for tilling the soil. Understanding the function of each component helps in identifying wear and tear, which is vital for efficient repairs.

Identifying Common Issues

Over time, components may wear out or become damaged due to regular use. Problems with the engine, drive system, or attachments can significantly affect performance. Familiarizing yourself with the typical issues in each area will allow you to quickly pinpoint where the problem lies. Regular inspections and a good knowledge of the machine’s structure ensure you catch potential failures before they disrupt your gardening tasks.

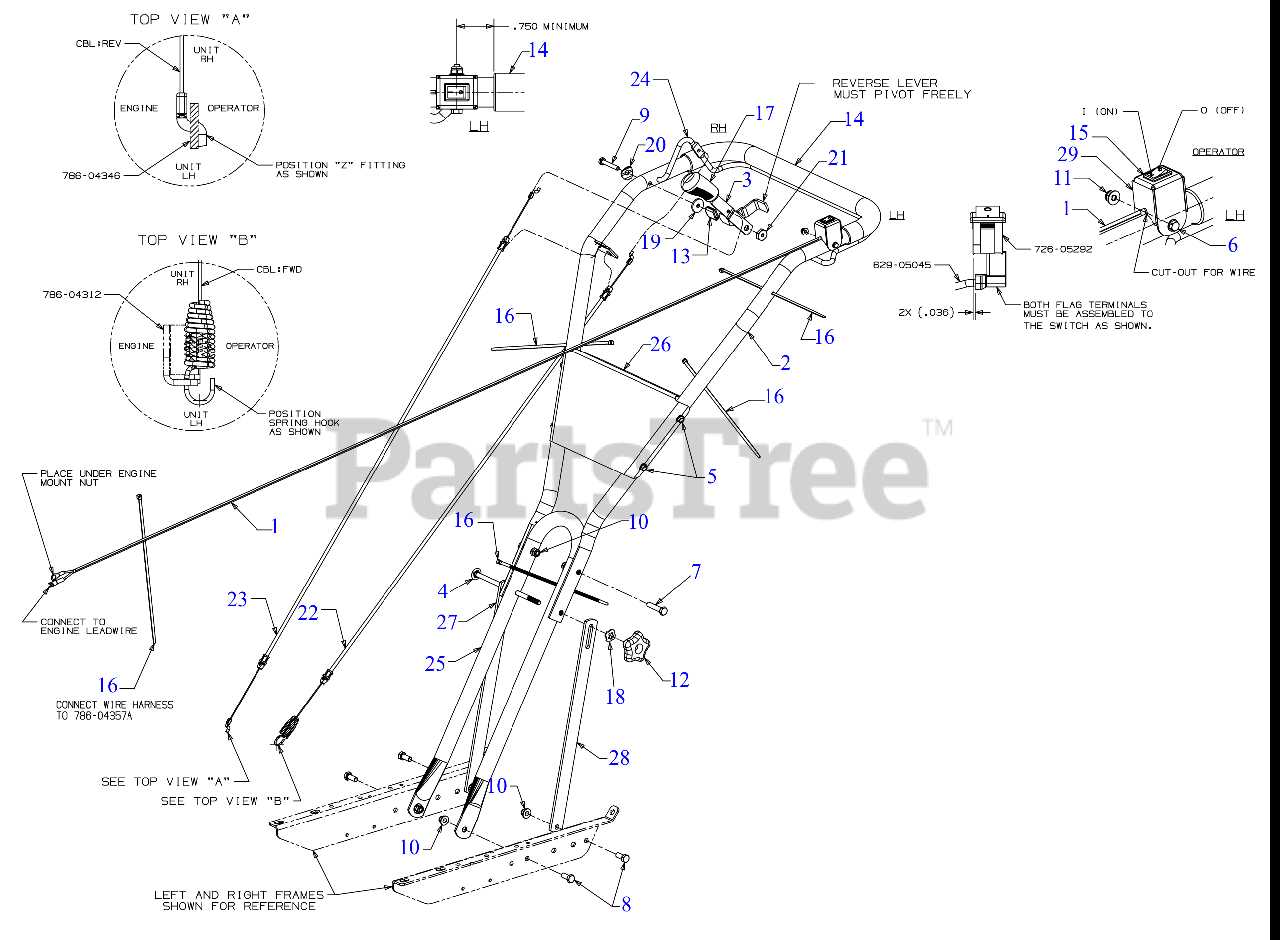

How to Read the Assembly Chart

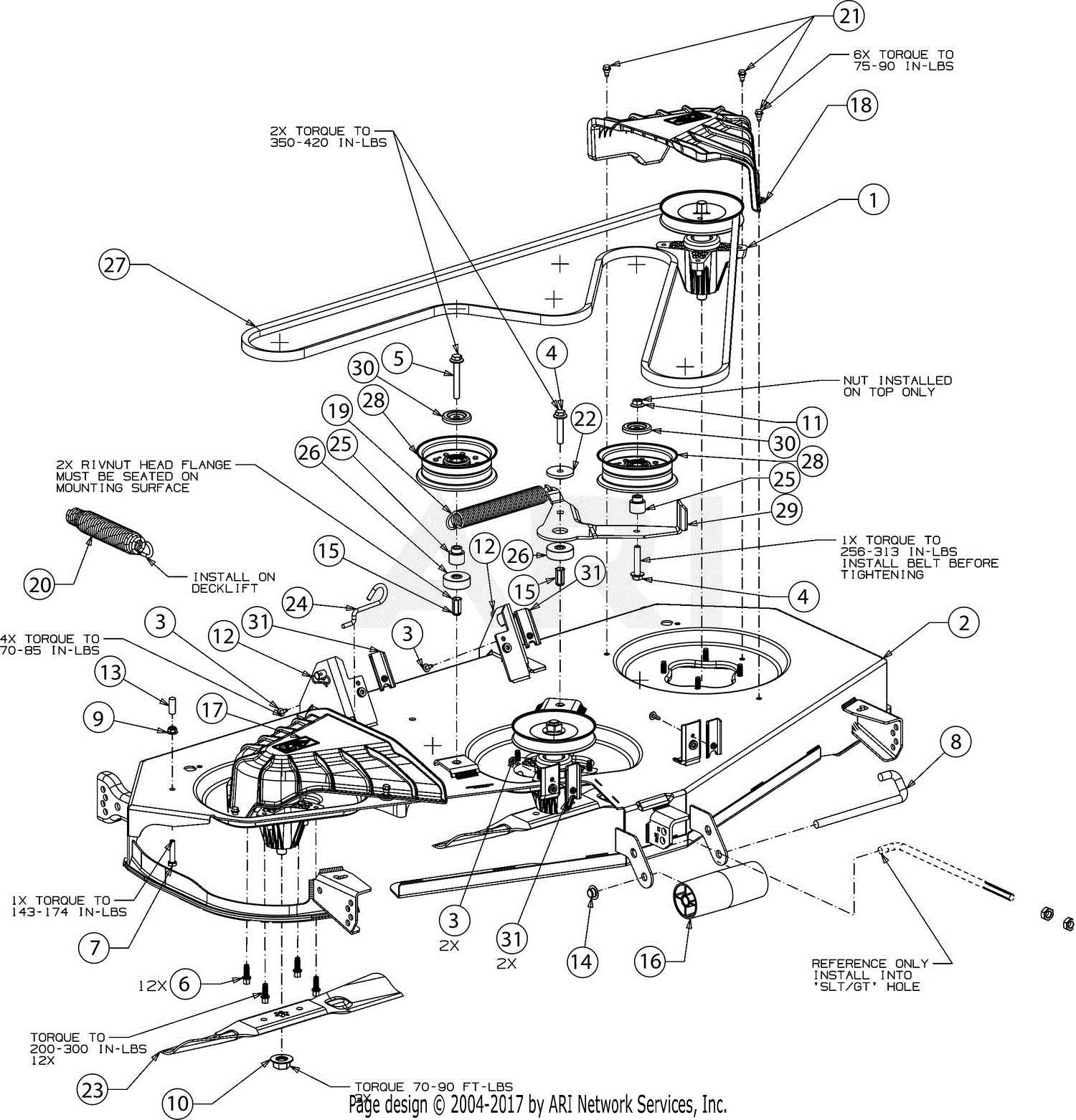

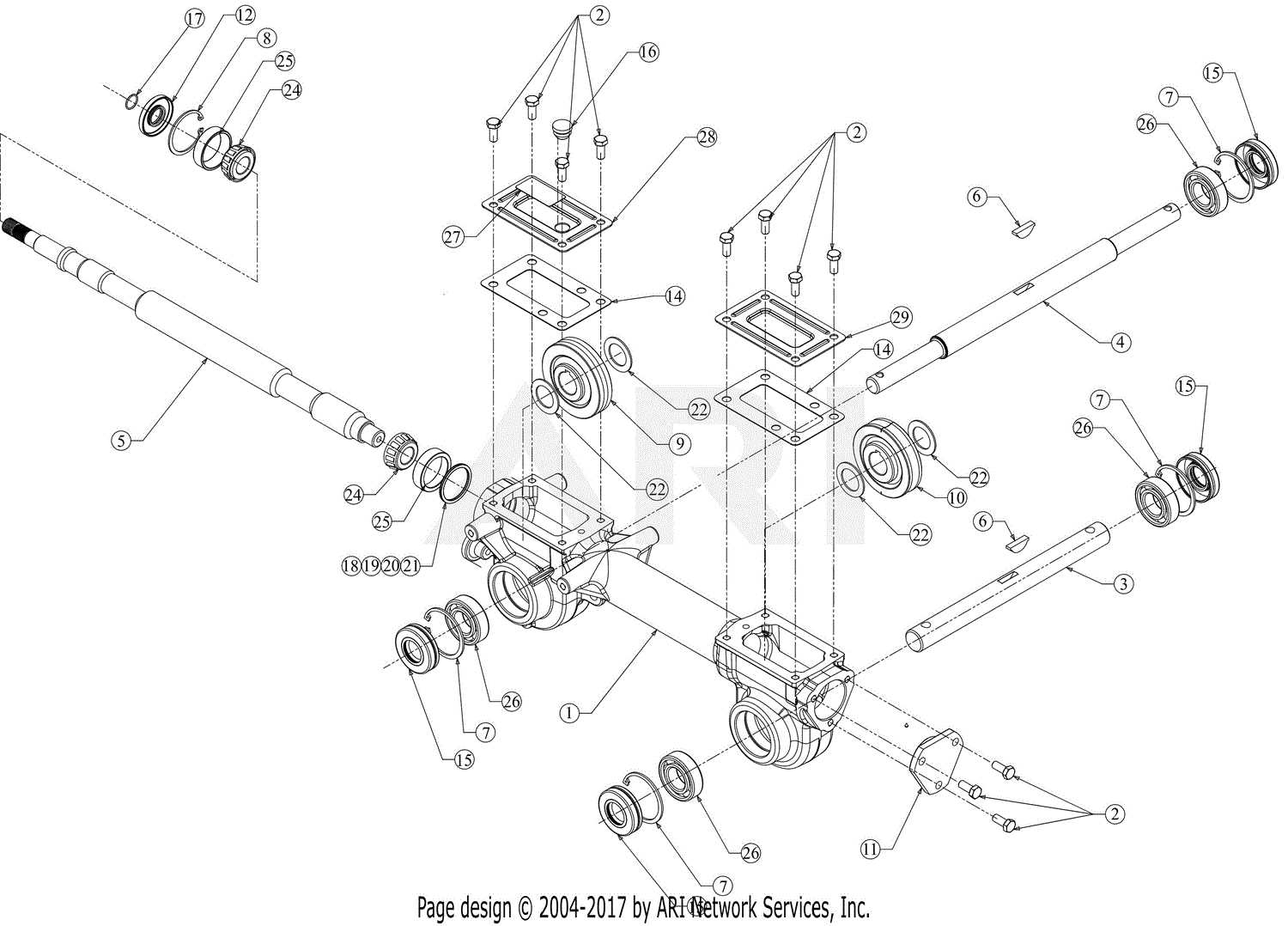

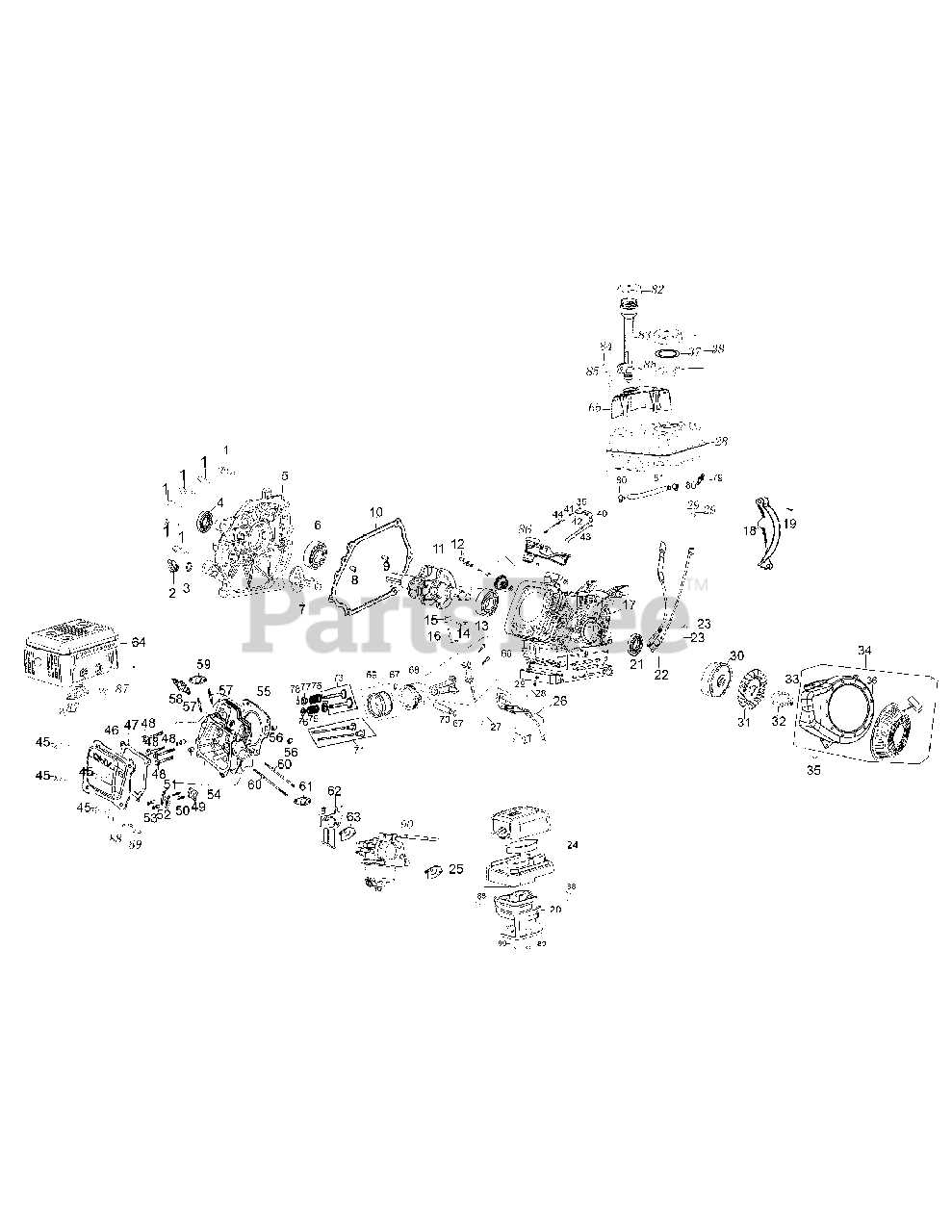

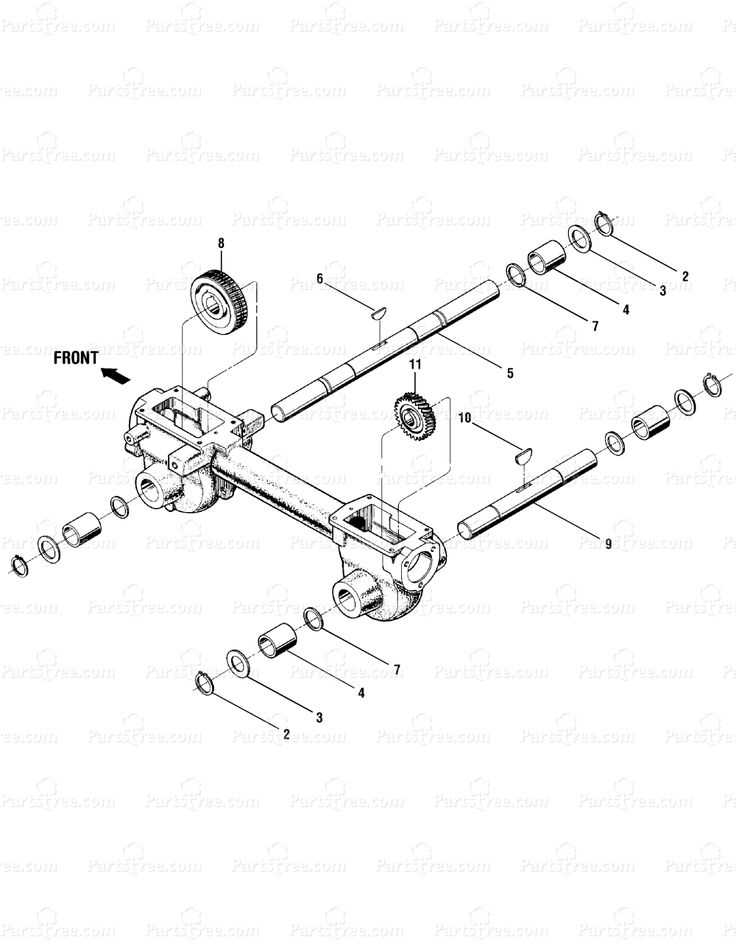

Understanding how to interpret an equipment schematic is essential for performing accurate repairs and maintenance. These visual guides show the layout of each component, how they are connected, and which parts are interchangeable. By familiarizing yourself with these charts, you can more easily locate specific pieces, order replacements, and understand how each part contributes to the overall function of the machine.

Identifying Key Sections

Most schematics are divided into sections, each focusing on a different part of the equipment. These sections typically show the components in their assembled state, with clear labels and numbers indicating their exact location. In addition, lines may connect different parts to show how they interact or are mounted within the machine. Pay close attention to these details, as they can help you determine the proper installation or disassembly steps.

Using the Reference Numbers

Reference numbers next to each part are crucial for ordering replacements or identifying specific components. These numbers are usually linked to a part list or catalog, where you can find more detailed information about the component’s specifications, compatibility, and cost. By matching the numbers on the schematic with the list, you can easily ensure you are replacing the right parts for your machine.

Common Repairs for Garden Equipment

Like all machinery, garden tools often require repairs due to wear and tear from regular use. Understanding the most common issues and how to fix them can help you save time and money. Whether it’s a problem with the engine, attachments, or the drive system, many repairs are straightforward and can be tackled with the right knowledge and tools.

Engine Performance Issues

One of the most frequent problems involves engine performance. Issues such as difficulty starting, rough running, or stalling often point to issues with the fuel system, spark plug, or air filter. Regularly replacing the air filter and cleaning or replacing the spark plug can restore optimal performance. If the engine is not starting at all, it’s important to check the fuel lines for clogs or leaks.

Drive System Failures

The drive system is essential for transmitting power from the engine to the working parts of the machine. Over time, components like the belt or gears can become worn or damaged. If the machine is moving slowly or not at all, inspect the drive system for broken or loose parts. Replacing or tightening the belt or fixing damaged gears will typically resolve the issue and restore full functionality.