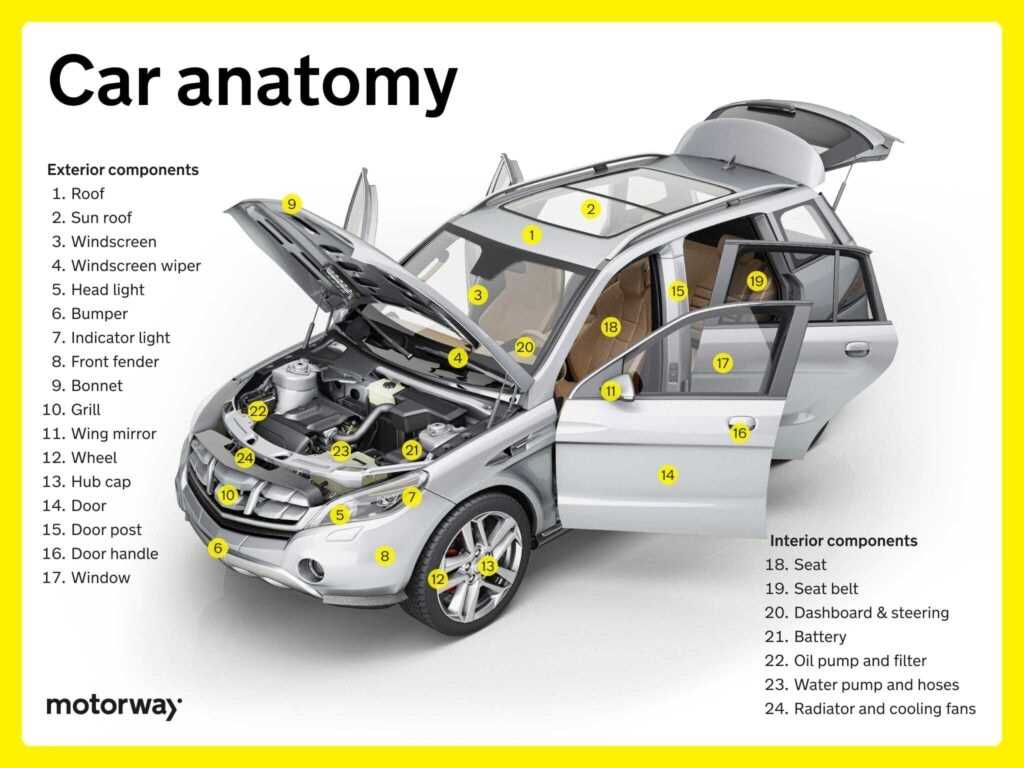

When it comes to machinery, a detailed map of its internal structure is crucial for maintenance, repairs, and assembly. These representations provide insight into the different sections and how they work together to ensure optimal performance. Each part plays a unique role, contributing to the overall functioning of the system.

Understanding these schematics allows technicians and enthusiasts to pinpoint issues, make adjustments, or even upgrade certain areas with precision. Knowing the layout and function of each element ensures that any intervention will be both effective and safe.

Without a clear representation, it would be difficult to track the intricate relationships between various components. By studying how these elements interact, individuals can make more informed decisions when managing or improving machinery.

Understanding Vehicle Diagrams and Components

For any complex machine, it is vital to have a clear understanding of how its individual elements are organized and connected. These visual representations offer a structured overview, allowing users to comprehend the relationships and functions of each section. Having such maps is crucial for anyone working with machinery, whether it’s for repair, maintenance, or general knowledge.

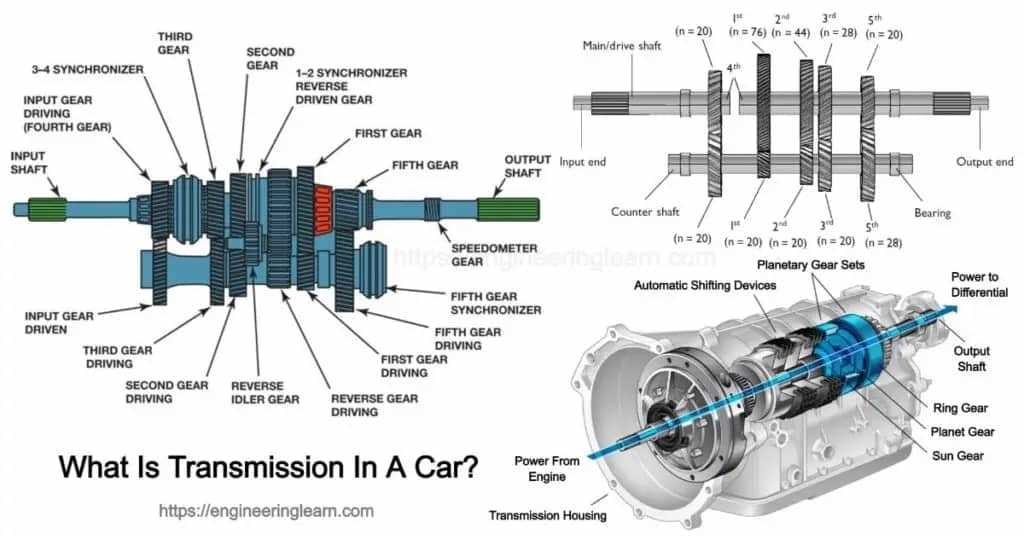

How Internal Elements Interact

Each segment of a system serves a specific function, but its effectiveness relies on its connection with others. These visual tools help highlight the flow of energy, signals, or mechanical movement between the parts, making it easier to troubleshoot or optimize performance. Whether it’s understanding how power is transmitted or how signals are routed, these depictions break down the complexity of the machinery.

Benefits of Detailed Schematics

When working with machinery, having access to detailed layouts can prevent costly mistakes and save time. These clear depictions offer a roadmap for anyone who needs to work on the system, from basic repairs to advanced adjustments. Additionally, accurate schematics ensure that technicians can quickly identify malfunctioning areas and address them promptly, avoiding potential damage.

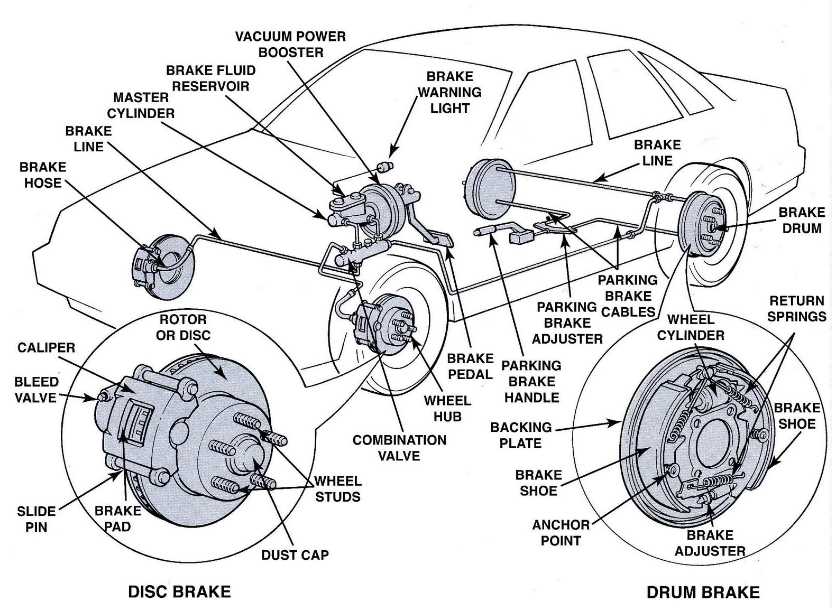

How Vehicle Parts Interact in Diagrams

The inner workings of any machine are based on the interaction of its many components. These connections are crucial to the overall function, and understanding how one element influences another is key to effective maintenance and troubleshooting. Visual representations help highlight these relationships, providing clarity on how different sections work together to ensure smooth operation.

Flow of Energy and Signals

In many systems, energy or signals flow from one component to another, triggering actions that keep everything in motion. These interactions are often depicted in a way that shows how the output of one element feeds into the next, enabling users to follow the energy or signal path through the whole system. Such understanding is essential for diagnosing malfunctions or planning upgrades.

Mechanical Linkages and Control

Mechanical elements are often linked together in complex arrangements, where the movement of one part affects the others. These relationships are mapped out in visual forms to show how a force applied to one component can cause a reaction elsewhere. By understanding these control links, users can identify potential problem areas and ensure everything is properly aligned.

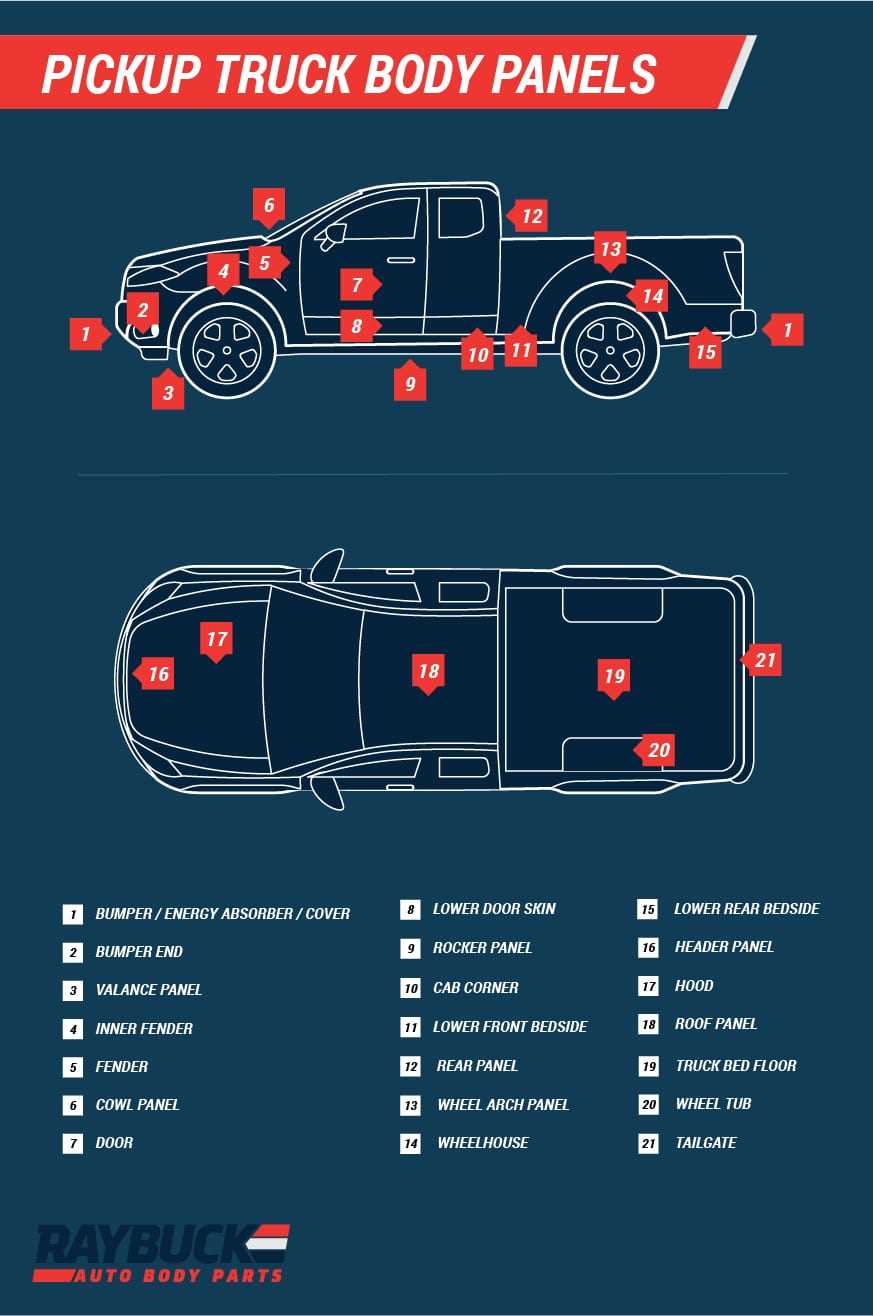

Importance of Accurate Vehicle Schematics

Having precise and reliable representations of a system’s internal structure is crucial for anyone working with machinery. These visual maps are essential tools for understanding how different components function together and ensuring that each part is in its correct place. Without accurate schematics, identifying issues and making necessary adjustments becomes significantly more difficult.

Ensuring Efficient Repairs and Maintenance

When a problem arises, detailed and correct schematics provide a clear guide for technicians to identify the root cause quickly. An accurate map of the system makes it easier to find malfunctioning areas, plan repairs, and replace damaged elements. This level of precision helps reduce downtime and ensures that the system continues to operate efficiently.

Preventing Damage and Miscommunication

Inaccurate representations can lead to costly mistakes, causing unnecessary damage to parts or miscommunication between team members. A clear, reliable schematic minimizes these risks by providing a consistent reference point for all involved in working on the system. Whether for repairs, upgrades, or regular inspections, accurate layouts are essential for maintaining safety and functionality.