Proper maintenance and replacement of key components are essential for ensuring the effectiveness of a vehicle’s reflection system. When individual elements wear out or break, it becomes crucial to identify the exact pieces involved for swift repairs or replacements. Recognizing these parts helps streamline the process, saving both time and effort during vehicle upkeep.

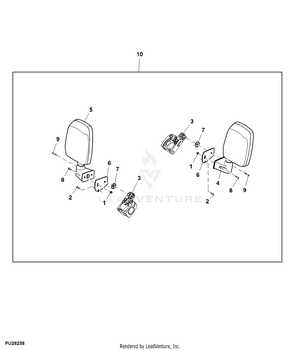

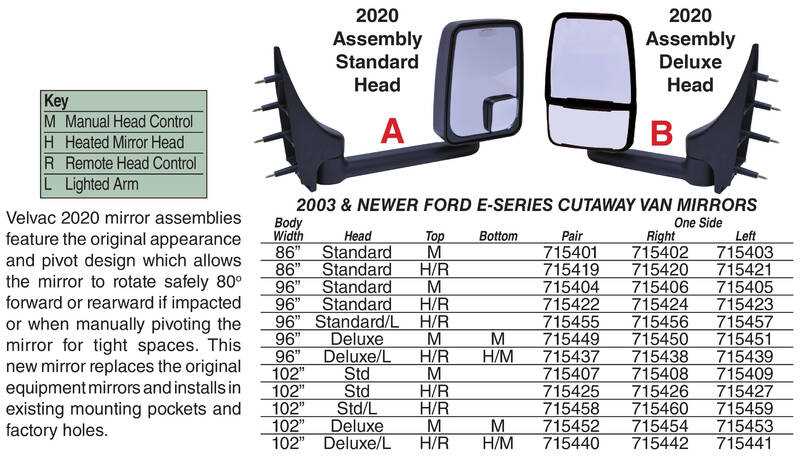

To assist in identifying the right components, it is useful to consult a detailed guide that outlines each piece’s function and position within the assembly. This kind of reference helps vehicle owners or repair technicians understand the overall structure and the specific role of each element in the system. Whether you’re looking to replace a single part or perform general maintenance, having the correct information at hand is vital.

Accurate identification of parts ensures compatibility and prevents costly mistakes. Detailed schematics not only clarify the role of each component but also enhance the overall efficiency of the repair process. With the right knowledge, handling repairs becomes straightforward and hassle-free.

Understanding Vehicle Reflection System Components

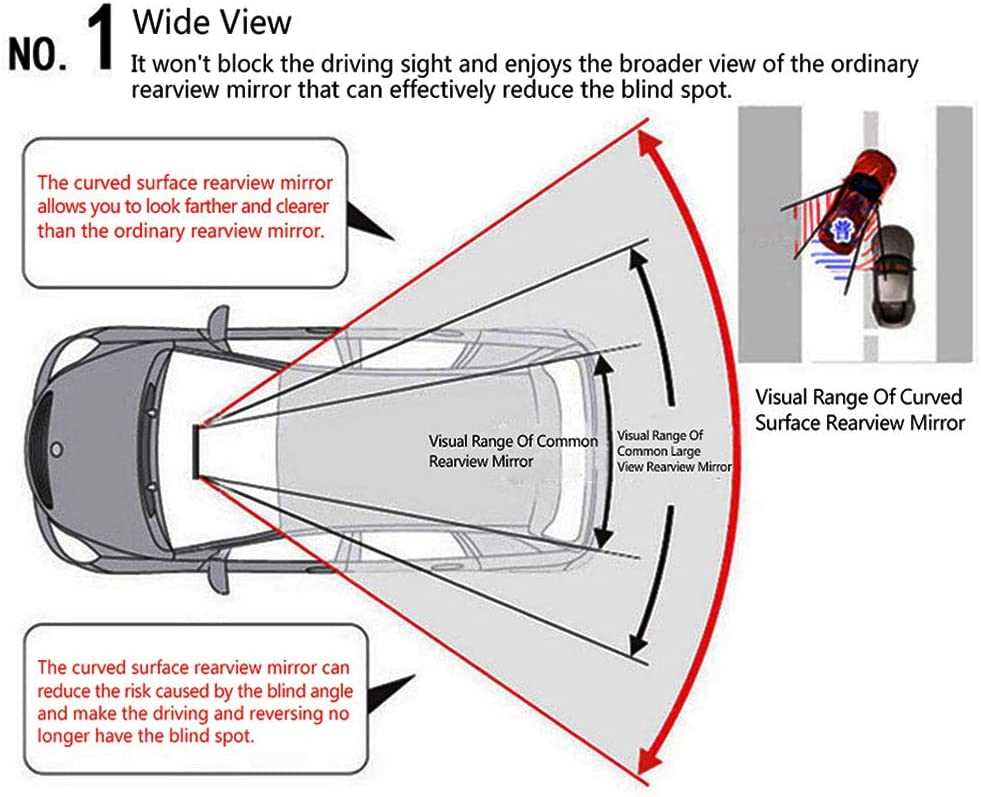

In any vehicle, the reflective system plays a critical role in providing visibility and safety. Each component within the assembly is designed to work together, ensuring clear sightlines for drivers and preventing potential hazards. Familiarity with the different elements and their functions is key to proper maintenance and repair.

At the core of the system, several components are responsible for maintaining the integrity and performance of the entire setup. From the main housing to the adjustment mechanisms, each part has a specific purpose. Understanding how these parts interconnect is essential for troubleshooting any issues or replacing a faulty component.

Critical elements like the reflective surface and mounting brackets are often the first to be inspected when a system fails to perform. Adjusting mechanisms allow for fine-tuning the angle of visibility, while the housing ensures that all parts remain secure. By understanding these components, vehicle owners can make informed decisions when replacing or maintaining their systems.

How to Identify Reflection System Components

When troubleshooting or replacing elements within a vehicle’s reflection system, recognizing individual components is the first crucial step. The correct identification ensures that repairs are accurate, preventing unnecessary replacements and ensuring the system functions optimally.

Check for Manufacturer Labels

One of the easiest ways to identify a specific part is by looking for manufacturer labels or model numbers. These identifiers are often located on the back or underside of the housing, providing important details about the part’s specifications.

- Look for stickers or embossed numbers on the casing.

- Use the model or serial number to search for replacement parts.

- Cross-check with the manufacturer’s catalog to verify compatibility.

Examine the Functional Features

If no labels are available, you can often identify the parts by examining their functions. Each component has a particular role, whether it’s adjusting the angle, securing the structure, or providing a reflective surface.

- The adjustment mechanism is typically a rotating knob or lever.

- The mounting bracket will feature holes for securing it to the vehicle.

- The protective covering may include a rubber seal to prevent damage from the elements.

Replacing Reflection System Components Made Easy

Replacing damaged or worn-out components in a vehicle’s reflection system doesn’t have to be a complicated task. With the right tools and a clear understanding of each element’s role, the replacement process can be quick and efficient. Knowing how to identify and access the required parts is the first step to successful repairs.

Start by gathering the necessary tools, which typically include basic hand tools such as screwdrivers, wrenches, and pliers. Carefully remove the old component without damaging the surrounding structure. Once the part is removed, make sure to check for any additional damage that may have occurred due to wear and tear.

When installing the new part, ensure it is securely fastened and properly aligned with the existing setup. Follow any provided instructions carefully to guarantee the component functions as intended. Regular maintenance can also help prolong the lifespan of the entire system, reducing the need for frequent replacements.