When working with complex outdoor equipment, it’s essential to understand the various components that make up the machinery. Knowing how each part functions helps in troubleshooting, maintenance, and ensuring smooth operation. A detailed map of these elements can significantly enhance your ability to manage the tool’s performance.

In-depth knowledge of the system allows users to identify issues quickly and recognize the need for repairs or replacements. Whether you’re a professional or a hobbyist, having a clear understanding of the machinery’s setup ensures efficient use and longer equipment lifespan.

Familiarizing yourself with the key elements of the machine provides confidence when handling repairs or adjustments. With the right visual guide, maintaining the tool becomes a more straightforward and manageable task.

Understanding the Key Components of the Equipment

To properly operate and maintain heavy machinery, it is crucial to comprehend the layout and functionality of its core elements. Recognizing the various pieces that work together ensures that users can identify issues quickly and perform necessary repairs efficiently. A well-maintained setup leads to improved performance and longevity of the machine.

Essential Components for Effective Operation

The heart of any outdoor machine lies in its central components. These elements are responsible for driving the machine’s movement and enabling it to perform its primary task. From the power system to the cutting mechanism, understanding each part’s role helps users to troubleshoot potential problems with precision.

Maintenance and Troubleshooting Insights

Regular inspection and proper maintenance can prevent many common issues that arise with complex machinery. Knowing how to assess each component’s condition allows for timely interventions before minor faults turn into major repairs. By understanding the inner workings, operators can ensure their equipment continues to function smoothly for years.

How to Identify Key Parts in the Diagram

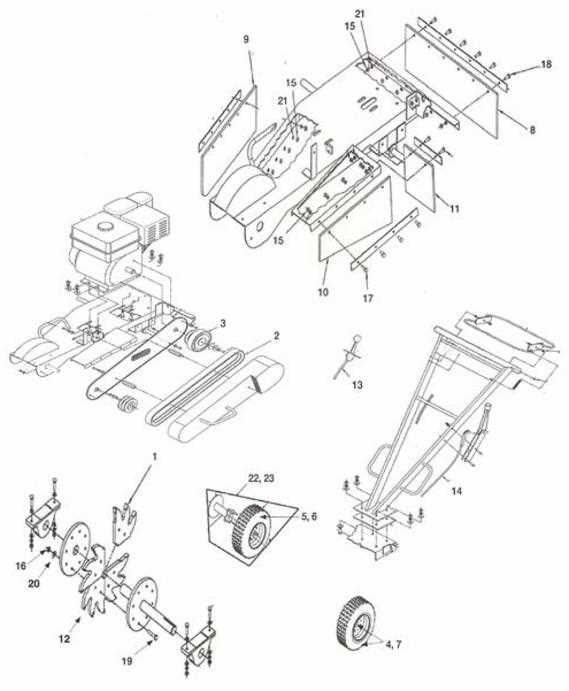

Understanding the layout of an outdoor machine requires more than just knowing its external features. By closely examining a visual representation of its internal components, operators can pinpoint critical elements responsible for the machine’s overall functionality. Learning to recognize each part ensures that users can make informed decisions when performing maintenance or repairs.

Start by familiarizing yourself with the basic structure of the system. Focus on identifying the major assemblies first, such as the drive mechanism and cutting elements. These are usually the most crucial components that directly impact performance. Once you have a clear understanding of these, it becomes easier to locate secondary parts that assist in supporting the primary functions.

Many diagrams will use color coding or labels to help distinguish different sections, so pay attention to these details for a clearer interpretation. By practicing this process, you will be able to quickly identify the right component in any situation.

Common Issues with Machine Components

Like all complex machinery, outdoor equipment often experiences issues that stem from wear and tear, improper maintenance, or external factors. Identifying these common problems early on can prevent costly repairs and ensure the machine remains operational for as long as possible. Understanding the frequent failures of key components helps users stay ahead of potential malfunctions.

One of the most frequent problems involves the cutting system. Over time, these elements can become dull, misaligned, or damaged due to constant exposure to harsh conditions. Regular checks on these parts are essential to ensure they maintain optimal performance. Another common issue is related to the power transmission components, such as belts and drive shafts, which may wear out or break under heavy usage.

Corrosion and rust are also prevalent concerns for outdoor equipment, especially in humid or wet environments. Components exposed to moisture without proper protection are prone to deterioration. Regularly cleaning and lubricating these parts can help extend their life and prevent such issues from arising.