When dealing with lifting machinery, it is crucial to have a clear understanding of its individual elements and their interconnected roles. This knowledge allows for efficient operation, timely maintenance, and smooth troubleshooting when issues arise.

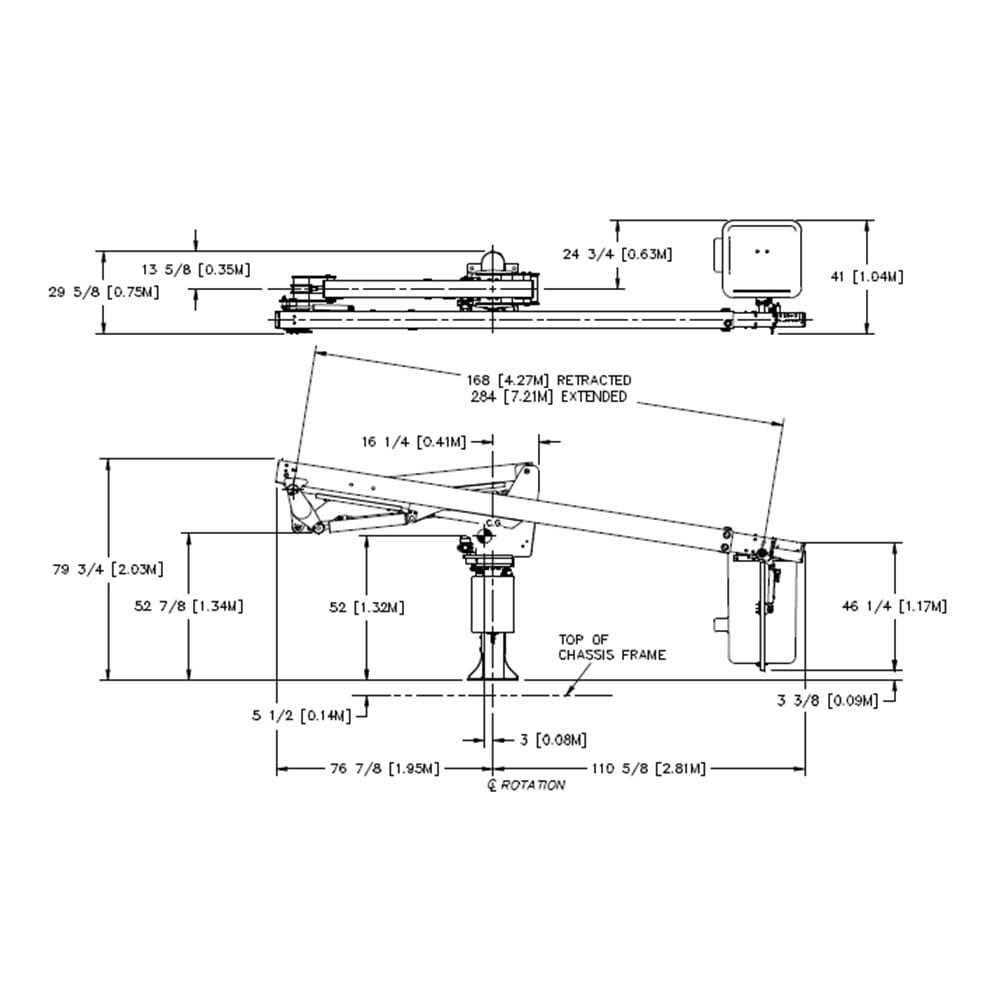

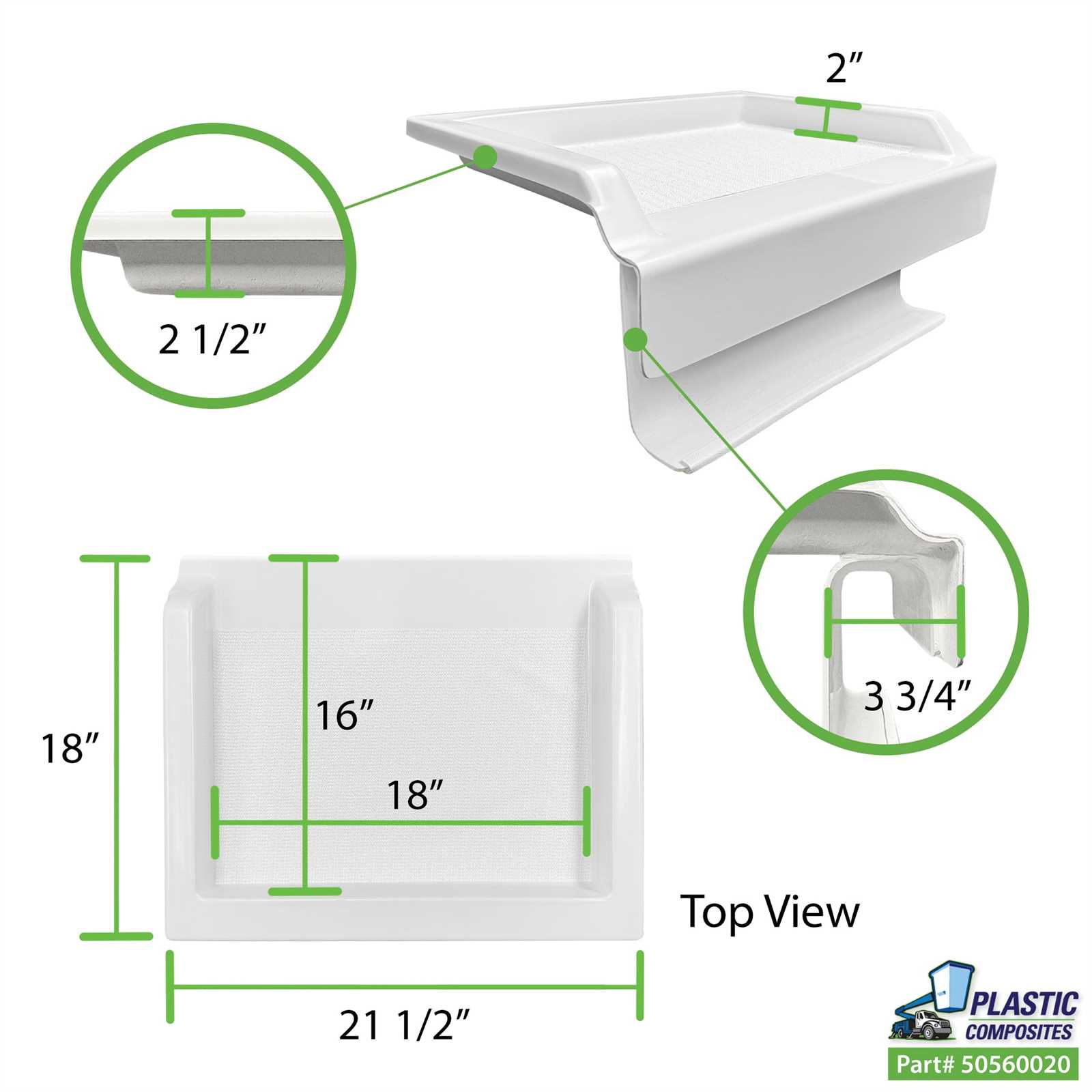

Each system is composed of various mechanical, electrical, and hydraulic components. Familiarity with their specific functions is key to ensuring everything works in harmony. A detailed schematic representation can greatly aid in identifying the layout and purpose of each part, making repair and maintenance processes much more manageable.

Proper knowledge of these components also helps in identifying potential problems early on, reducing downtime and ensuring safe operation. Understanding the configuration and interconnections of each part contributes to the overall longevity and reliability of the equipment.

Understanding Lift Equipment Components and Functions

To operate lifting machinery effectively, it is essential to comprehend the individual components that work together to ensure its performance. Each element plays a specific role, contributing to the smooth operation of the entire system.

Mechanical elements, such as hydraulic pumps and control valves, are responsible for power generation and the movement of various parts. These components work in tandem with electrical systems that control and monitor the machine’s functions, ensuring proper response and efficiency during use.

Understanding the layout of the entire assembly allows operators to identify each part’s role in the system, making it easier to troubleshoot issues or perform necessary maintenance. When operators are familiar with how each part contributes to the overall functionality, they can identify potential problems and address them before they affect performance.

How to Read the Equipment Schematic

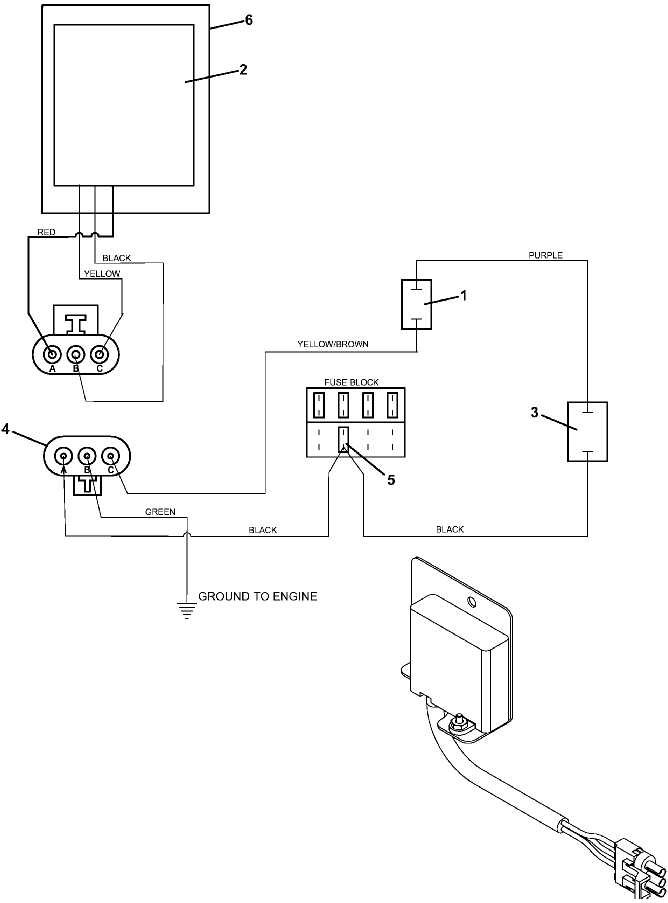

Interpreting the layout of lifting machinery requires an understanding of how various components are represented and connected. A visual map can provide valuable insights into the structure and relationships between different elements, helping operators and technicians quickly identify areas of interest.

Key symbols are often used to represent different components, such as valves, pumps, and motors. These symbols are standardized, making it easier to identify parts without needing to memorize every detail. Each line and connection signifies the flow of power, fluid, or electrical signals, which helps in understanding the system’s operation.

Reading the schematic involves tracing the connections between components, noting how they interact within the system. By following the lines and understanding their meaning, it becomes easier to pinpoint issues or plan repairs efficiently. Familiarity with this visual representation enhances overall maintenance and troubleshooting efforts, leading to more effective problem-solving.

Common Maintenance Tips for Lift Equipment Components

Proper maintenance is essential for ensuring the longevity and reliable performance of lifting machinery. Regular checks and care help prevent costly repairs and downtime, ensuring smooth operation. Below are several key tips for maintaining the core elements of the system.

- Inspect hydraulic systems regularly for leaks or wear. Ensure that fluid levels are sufficient, and that hoses and seals are in good condition to avoid performance issues.

- Check electrical connections to ensure all wiring is secure and free from damage. Corrosion can impair functionality, so connections should be cleaned and tightened periodically.

- Lubricate moving parts such as joints, pivots, and gears. Proper lubrication reduces friction and extends the life of the components.

- Monitor wear and tear on mechanical elements like chains and cables. Regular inspections help detect early signs of wear, preventing unexpected failures during use.

- Test safety features such as emergency stop functions and alarms. These systems are crucial for safe operation and should be regularly tested to ensure they function correctly when needed.

By following these tips, operators can extend the lifespan of key components and ensure the machine runs efficiently for a long time.