When maintaining or repairing an engine, understanding the various parts and their interconnections is crucial. A clear visual representation can simplify this process, helping users identify the correct components and understand their functions. This guide offers a detailed overview to assist with the identification of essential engine elements.

By closely examining the layout of the engine’s components, you can ensure that all parts are correctly assembled and functioning at their best. Whether you are an experienced technician or a beginner, having a precise reference is invaluable when working on engine repairs or upgrades.

In this section, we explore the key components found within the system, providing insights on their roles and how they interact with each other. Knowing how to interpret these visuals is a significant advantage when performing diagnostics or repairs on your engine.

Understanding the Engine System

Every engine relies on a complex arrangement of components working together to provide reliable power. This system is designed to operate efficiently under various conditions, ensuring smooth performance whether used for recreational or professional purposes. Understanding how each part functions and supports the overall engine is essential for effective maintenance and troubleshooting.

Key Engine Elements

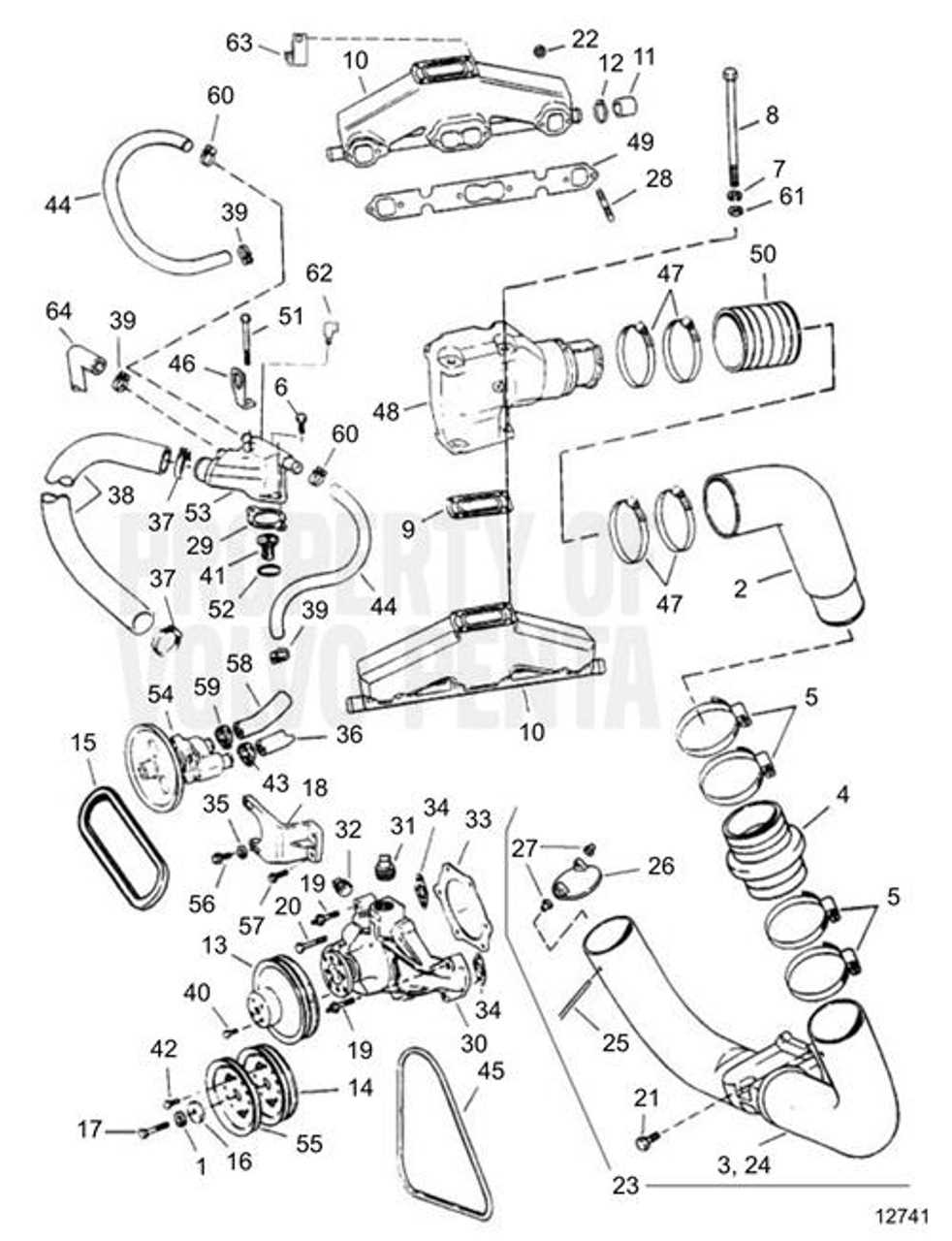

Among the most important elements are the ignition system, fuel delivery components, and cooling mechanisms. These work together to ensure the engine operates at optimal temperatures and efficiency. Additionally, the propulsion system plays a critical role in converting engine power into motion, providing the necessary thrust for the vessel or vehicle.

Common Maintenance Practices

To ensure the longevity and performance of any engine, regular maintenance is required. This includes checking fluid levels, inspecting belts and hoses, and replacing worn-out components. Proper care of the engine ensures it continues to function smoothly, preventing costly repairs and unexpected breakdowns.

Essential Components in the System Layout

An engine’s effectiveness relies heavily on the integration of key components, each with a specific function that supports the overall performance. Identifying and understanding the role of these critical elements ensures the system operates efficiently and is easier to maintain. Knowing how they interact within the entire structure helps in diagnosing potential issues quickly.

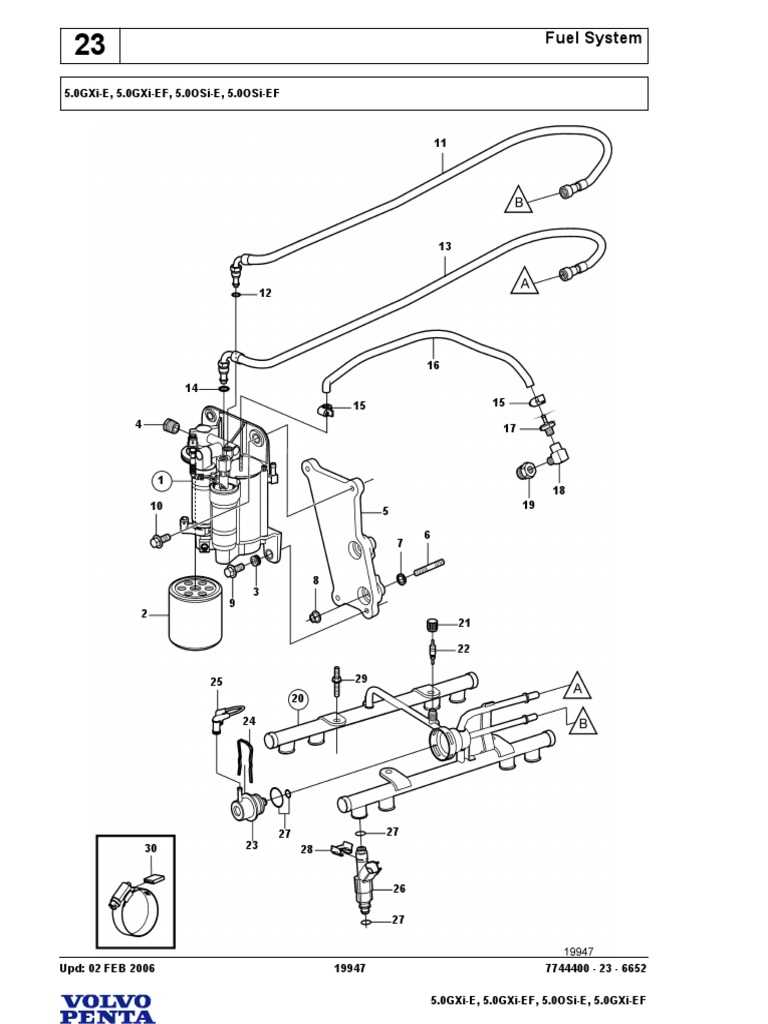

Some of the most important elements include the fuel system, which is responsible for delivering the proper mixture to the engine, and the ignition system, which ensures timely combustion. Additionally, the cooling system prevents overheating, while the exhaust system manages emissions. Each component must work seamlessly with the others to guarantee optimal operation.

Properly identifying and replacing these key components as needed ensures the engine runs smoothly and prevents failures. By closely examining their arrangement and function, technicians can maintain peak engine performance over time.

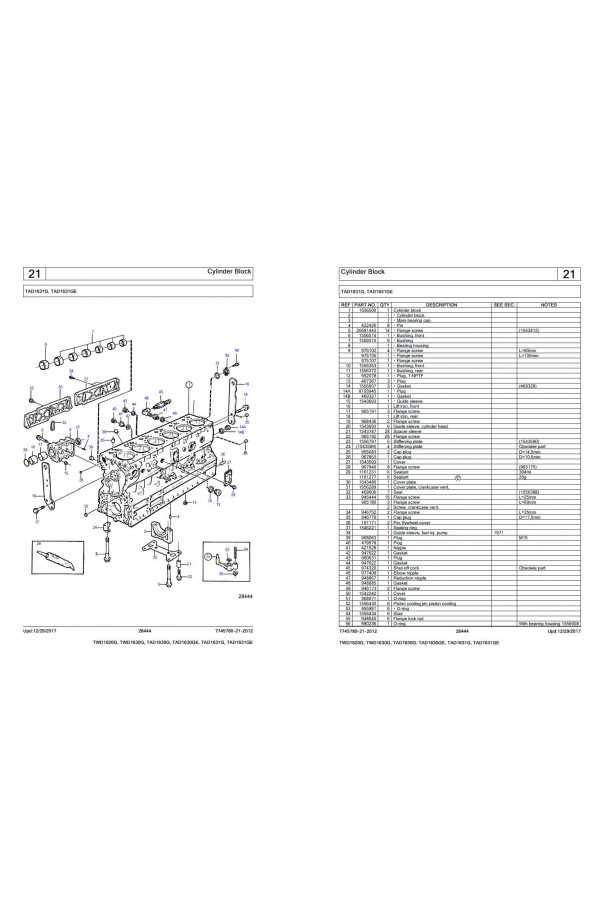

How to Read the System Layout

Understanding the visual representation of engine components is essential for effective repairs and maintenance. These diagrams are structured to provide clarity on how various parts are arranged and interconnected. By learning how to interpret these layouts, technicians can quickly identify each part and its role within the system.

To read the system layout correctly, follow these steps:

- Start by identifying the major sections, such as the fuel, ignition, and cooling systems.

- Look for labels and numbers that correspond to specific components.

- Study the connections between different parts, noting how they interact with each other.

- Use the key or legend to understand symbols or abbreviations used in the diagram.

Understanding these elements will help ensure that every part is in its correct position and function, making it easier to spot potential issues or plan maintenance activities.