When maintaining and repairing a marine propulsion system, understanding the intricate components is essential. A clear visual representation of these elements helps owners and technicians identify individual parts, their functions, and how they interact within the larger assembly. With the right knowledge, performing efficient maintenance or troubleshooting becomes much easier.

The importance of having access to a detailed guide cannot be overstated. By studying the specific components that make up the system, users can enhance their ability to detect issues and replace faulty parts. In this guide, we will dive deep into the critical elements that make up these mechanical structures, offering insight into each piece’s role in ensuring smooth operation.

Proper maintenance and a thorough understanding of the assembly allow for better performance, longer lifespan, and reduced downtime of the vessel. Whether you’re a technician or a boat owner, having a solid grasp of these technical details will improve your approach to maintaining your marine vessel.

Understanding the Marine Drive System

Marine propulsion units are complex assemblies that play a crucial role in a vessel’s movement. These systems are designed to convert engine power into forward or backward motion, making them a vital component of any boat. A thorough understanding of the structure and function of each part is essential for proper maintenance and troubleshooting, ensuring the vessel runs efficiently in various conditions.

Key Functions and Design

The primary function of this mechanical assembly is to transfer power from the engine to the water propellers. It involves several interconnected parts that work together to manage thrust, speed, and steering. The design is carefully crafted to withstand the harsh marine environment, offering durability and performance. Understanding how each piece contributes to the overall function can help identify potential issues and improve the system’s reliability.

Maintenance and Troubleshooting

Regular inspection and maintenance of the assembly are necessary to ensure optimal performance. By familiarizing oneself with the structure, boat owners and technicians can spot signs of wear or malfunction early, preventing costly repairs. The longevity of the propulsion system relies on proper care, so knowledge of its components is essential for anyone involved in maintaining marine vessels.

Key Components of the Drive System

The drive system consists of various mechanical elements working together to propel the vessel forward and steer it effectively. Each component has a specific function that contributes to the smooth operation of the system. Understanding these parts and their relationships is crucial for efficient troubleshooting, maintenance, and repair.

Primary Drive Shaft and Gear Mechanism

The drive shaft plays a critical role in transferring power from the engine to the propeller. This shaft is connected to a set of gears that adjust the rotational speed and direction, allowing the vessel to move in different directions with control over its speed. The gear mechanism is vital for smooth transitions and ensuring power is applied correctly to the propeller.

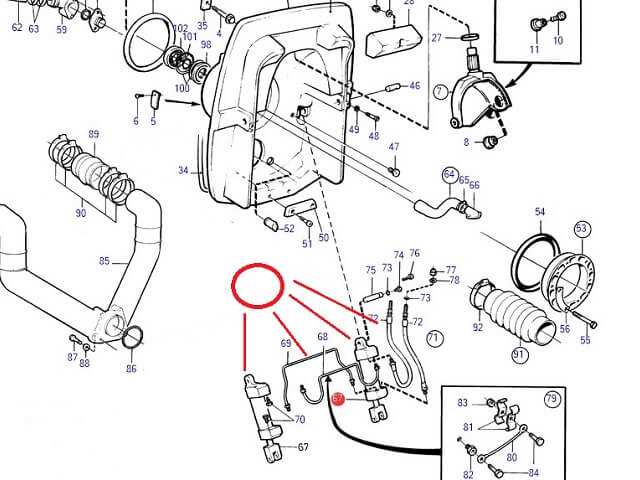

Steering and Trim Components

Steering elements in the system allow the operator to maneuver the vessel with precision, while trim components help adjust the angle of the drive unit to optimize performance. These components are essential for controlling the boat’s direction and maintaining stability while on the water. Regular maintenance of these parts is necessary for safe and reliable operation.

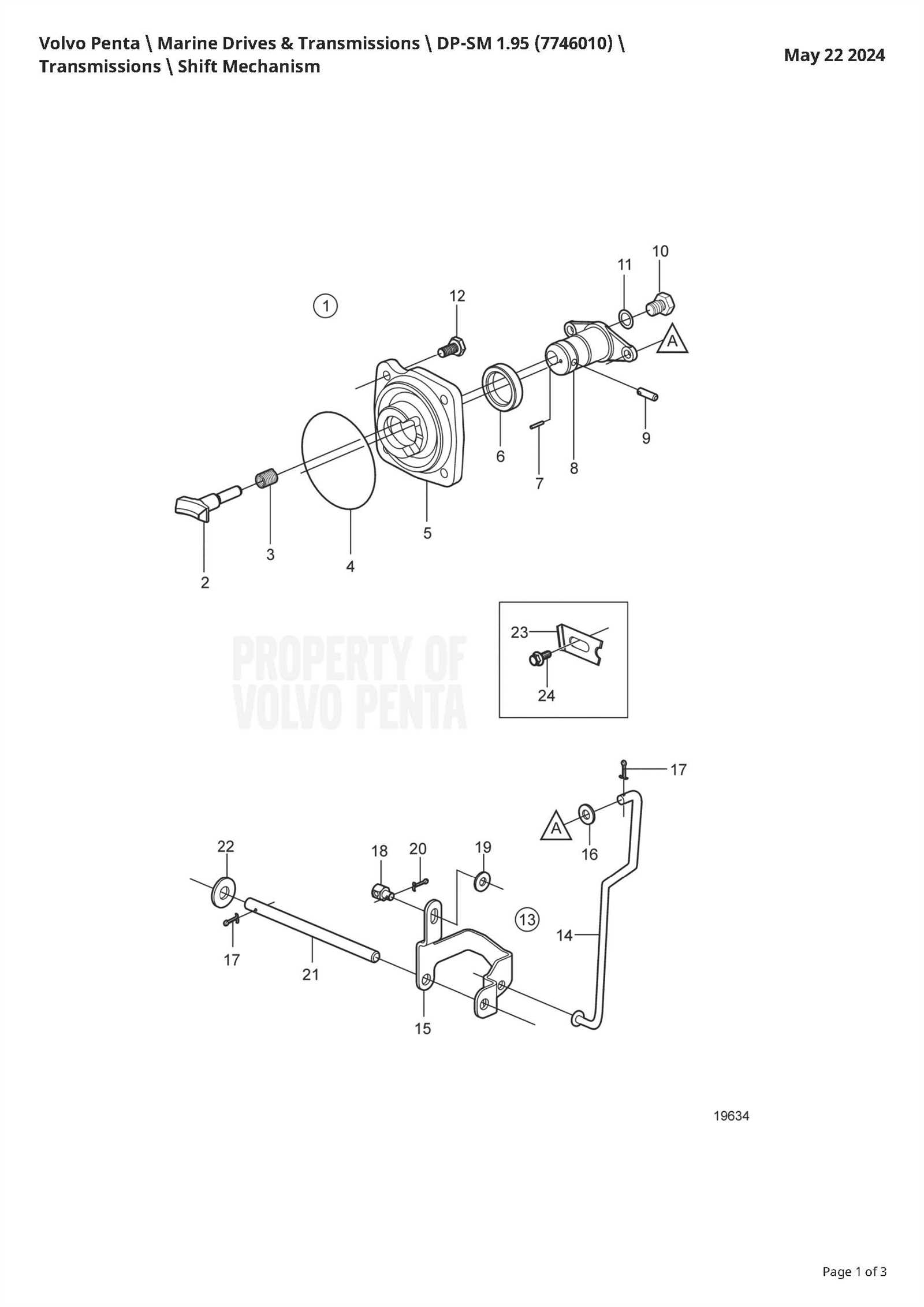

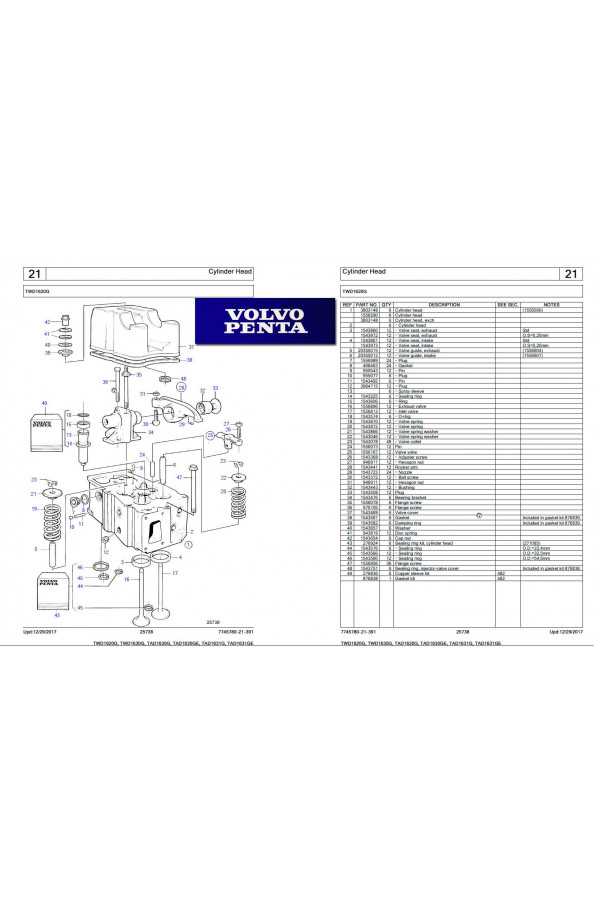

How to Read the Components Layout

Understanding how to interpret a system’s layout is key to effectively diagnosing and repairing issues. A well-organized visual guide shows the placement and connection of each component, making it easier to identify and address problems. By learning to read these representations, you can quickly find the parts that need attention and ensure proper assembly.

The key to reading this visual guide is recognizing the symbols and labels used to represent various components. Each part is numbered or marked, allowing you to match it with its corresponding description in the manual. Pay close attention to the relationships between the parts, as the arrangement helps in understanding how each element functions within the overall system.

Once you are familiar with the layout, you can use it to locate specific parts, assess wear, and identify potential issues that could affect performance. This method of referencing parts through a diagram is essential for making precise repairs and keeping the system running smoothly.