When it comes to maintaining and repairing marine engines, having a clear understanding of their internal structures is crucial. A detailed schematic helps users identify each component, ensuring effective troubleshooting and smooth operation. These layouts offer a visual representation of how various elements interact within the machinery.

By studying these visual guides, you can better comprehend the function of every part, whether it’s a vital system or a minor component. This knowledge makes it easier to perform maintenance tasks, locate potential issues, and replace damaged sections with confidence. Efficient management of these tasks leads to longer engine life and optimal performance.

Through an organized view of the engine’s internals, operators are empowered to take control of their maintenance schedules. With clear identification of each section, it becomes simpler to make informed decisions and reduce unnecessary repairs. Having access to such tools is invaluable for every engine owner.

Understanding Engine Component Layout

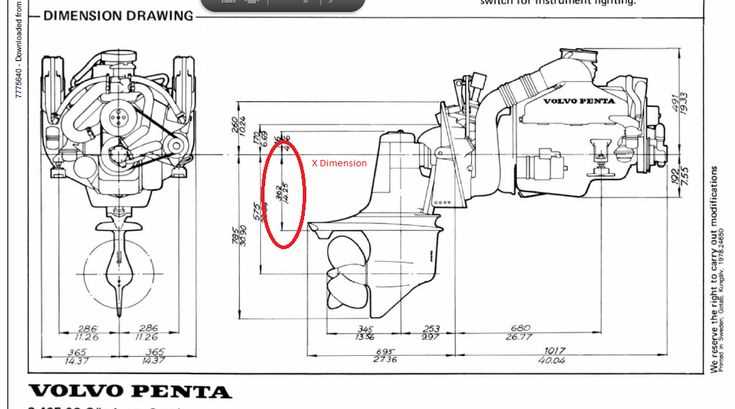

A comprehensive layout of an engine’s internal systems is essential for any operator or technician. By offering a clear visual representation, it allows individuals to identify the different elements that contribute to the overall functionality of the machine. Each section is organized in a way that simplifies understanding and enhances troubleshooting efforts.

These visual guides break down complex systems into easily recognizable components, helping users locate specific sections without confusion. From major engines to auxiliary systems, the layout offers a systematic approach to understanding how each part contributes to the overall performance. Having this clarity reduces the likelihood of mistakes and ensures maintenance tasks are carried out efficiently.

Moreover, an organized view of the engine’s structure makes it easier to track performance over time. Understanding how each component interacts with others provides valuable insight into potential issues, helping prevent costly repairs and downtime. This approach not only aids in repairs but also in regular servicing, ensuring the engine continues to operate at its best.

How to Read an Engine Schematic

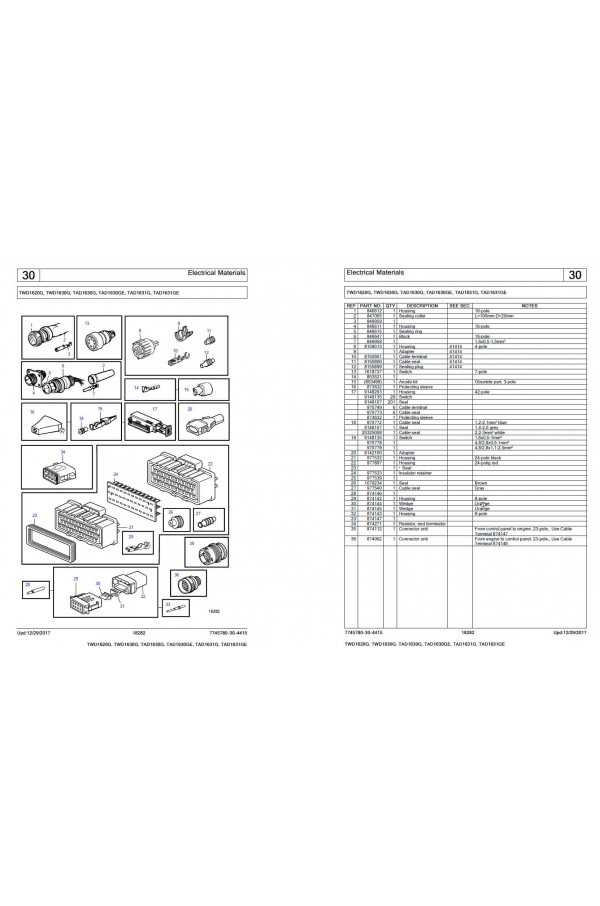

Understanding an engine schematic is a critical skill for anyone involved in maintenance or repairs. These visual tools display the layout of various components, helping users trace connections and functions across the entire system. Each element is represented by a unique symbol or label, making it easier to identify and work with individual parts.

To effectively read these schematics, start by familiarizing yourself with the legend or key. This will clarify what each symbol and line represents, whether it’s an electrical component, mechanical part, or fluid system. Once you understand the basic symbols, you can follow the layout to locate and assess the parts that need attention or replacement.

As you interpret the schematic, pay close attention to the flow of the systems. Arrows and lines often indicate movement or interaction, such as the flow of oil or coolant. Recognizing these connections is essential for troubleshooting and understanding how each part influences the overall function of the engine.

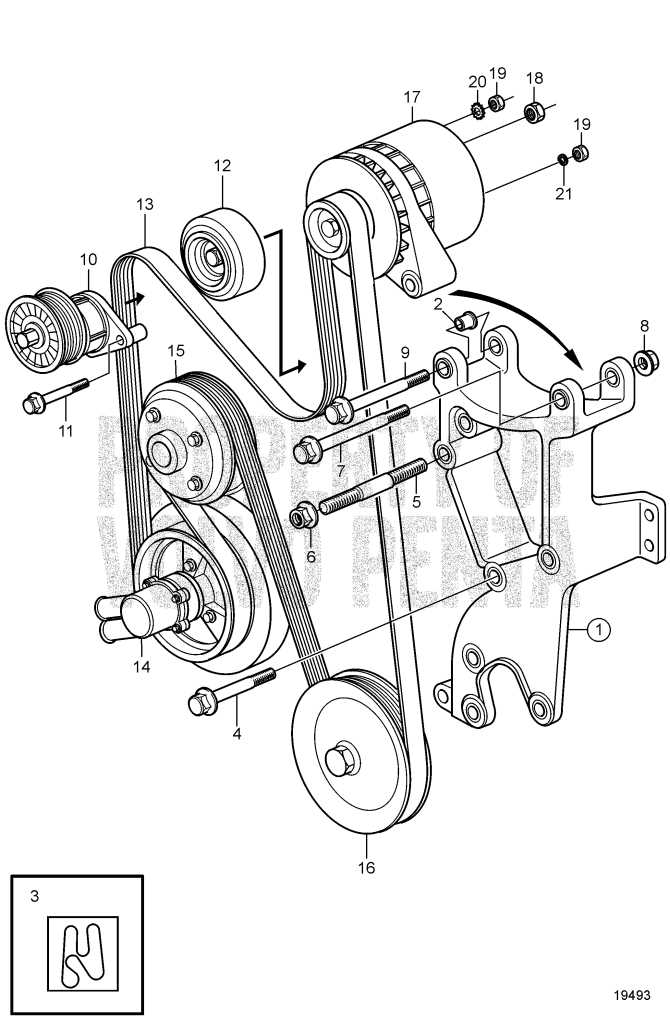

Essential Components of Marine Engines

Every marine engine is made up of several key systems that work in harmony to ensure optimal performance. These components are designed to support various functions, such as power generation, cooling, lubrication, and exhaust management. Understanding these essential parts is crucial for effective maintenance and troubleshooting.

One of the most important elements is the power unit, responsible for generating the necessary force to propel the vessel. Along with it, the cooling system maintains the temperature within safe operating limits, preventing overheating. The lubrication system ensures smooth operation by reducing friction between moving parts, while the fuel system delivers energy to keep the engine running efficiently.

Additionally, exhaust systems are designed to safely expel gases from the engine while minimizing emissions. Electrical and control systems help monitor the engine’s performance, providing critical data for operators. Recognizing the function of each of these components makes it easier to maintain and repair the engine when necessary, ensuring it runs at peak efficiency.