When it comes to maintaining heavy machinery, having a detailed reference to all its individual elements is crucial. These guides provide a visual map of how each component fits into the overall system, enabling more efficient troubleshooting and repairs. Whether you’re a technician or an owner, understanding these references can save both time and money in the long run.

Accurate identification of each part ensures that maintenance is performed correctly, avoiding costly mistakes. By following a clear breakdown of each element, users can easily determine the root cause of issues and resolve them faster. This not only improves machine longevity but also enhances performance.

Knowing how to read and interpret these visual aids allows for quicker diagnosis of malfunctions and a smoother repair process. In this article, we will explore how these guides work and how they can be leveraged to keep your equipment running in optimal condition.

Understanding Equipment Component Breakdown

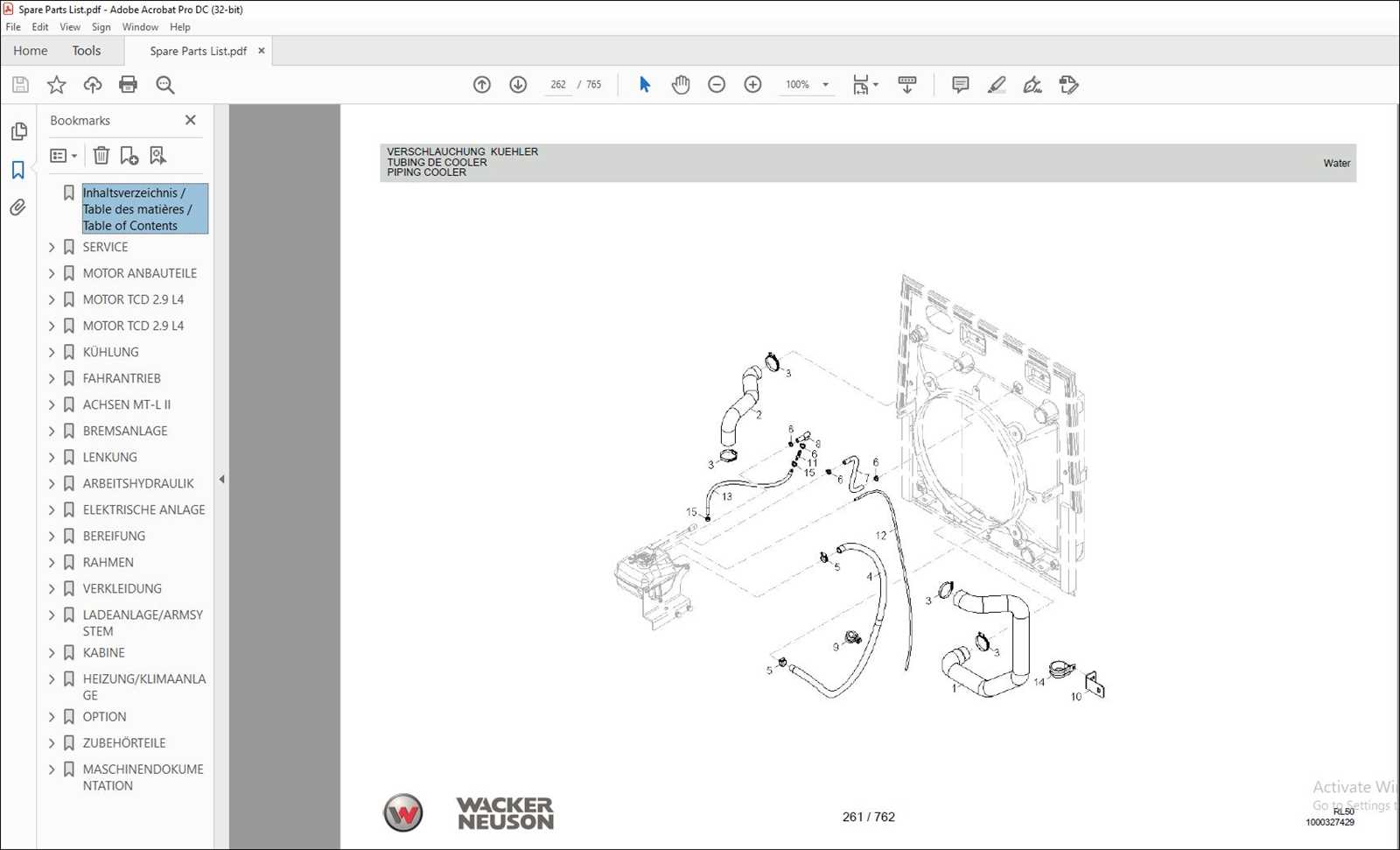

Knowing how to read a detailed component reference is essential for anyone involved in machinery maintenance. These guides break down complex machines into individual elements, allowing for a comprehensive understanding of how each piece contributes to the overall function. By identifying specific sections and their relationships, operators and technicians can address issues more efficiently and accurately.

The guide typically features a visual representation of the equipment, with each part labeled and numbered for easy identification. This makes it easier to locate and replace faulty components, ensuring repairs are done quickly without unnecessary errors.

- Accurate identification of every component for faster repairs

- Clear organization helps to minimize confusion during maintenance

- Essential for diagnosing issues in complex machinery

- Serves as a reliable reference for troubleshooting common malfunctions

These references are vital tools for maintaining optimal functionality, reducing downtime, and extending the equipment’s lifespan. Understanding the structure of the guide enables users to take full advantage of its benefits and ensures proper servicing of machinery when needed.

How to Use the Component Breakdown for Maintenance

Using a detailed visual reference for machinery maintenance is a crucial skill for technicians and operators. These guides allow for a quick overview of each element within a system, making it easier to locate and address any issues that may arise. Properly interpreting these references can significantly reduce repair time and improve overall maintenance efficiency.

Step-by-Step Approach for Effective Use

To begin, it’s important to familiarize yourself with the layout of the visual guide. Most references are organized by sections, with each part clearly labeled and numbered. Follow these steps to effectively use the guide:

- Identify the malfunctioning area in the equipment.

- Locate the corresponding section in the reference.

- Examine the components carefully to find the exact part that needs attention.

- Use the part number or description to find a replacement or service information.

Benefits of Using Visual References

By using these guides, maintenance professionals can quickly pinpoint specific components that need servicing. This minimizes downtime and avoids unnecessary disassembly of the machine. Additionally, accurate references ensure the right parts are replaced or repaired, helping maintain the machine’s performance and longevity.

Common Issues and Solutions Using Diagrams

While working with heavy machinery, various issues can arise, from worn-out components to misalignments. A comprehensive visual reference is invaluable in diagnosing these problems, allowing for a targeted approach to repairs. By understanding common issues and how to use the guide to resolve them, maintenance tasks become more efficient and less error-prone.

Frequent Problems and How to Identify Them

Several common problems can be easily identified through a detailed breakdown of the machinery:

- Loose or damaged connections: Check for any broken or misaligned joints within the specified sections.

- Wear and tear on moving parts: The guide will help locate components that are subject to frequent stress and require replacement.

- Overheating or poor performance: Inspect related parts for blockages or malfunctioning elements that could affect the machine’s efficiency.

Steps to Resolve Issues Using the Visual Guide

Once the issue is identified, use the visual guide to follow these steps:

- Locate the specific component in the breakdown that may be faulty.

- Verify the exact problem, such as wear or damage, by comparing it with the reference image.

- Replace or repair the faulty part based on the provided instructions or part numbers.

By effectively using these references, common issues can be diagnosed quickly and addressed before they lead to more severe damage, ensuring the longevity and efficiency of the machinery.