In order to effectively operate and maintain any heavy-duty construction equipment, it’s essential to have a clear understanding of its core components. Recognizing how each part functions contributes to better performance and longevity of the machine. Proper knowledge of the individual elements ensures smooth operation, minimizes wear, and aids in timely repairs.

Each machine is designed with specific parts that work together to deliver optimal results. From power transmission to vibration mechanisms, understanding how these elements interact is crucial. This knowledge not only helps in troubleshooting but also in performing regular maintenance, keeping the equipment in top working condition.

Recognizing each element and its function empowers operators and technicians alike to identify potential issues quickly, enhancing both safety and efficiency. With the right guidance, anyone can gain insights into the intricate workings of these robust machines.

Understanding Vibratory Machine Components

For efficient operation and longevity, it’s essential to understand the various components of any heavy-duty machinery. Each element plays a crucial role in ensuring the machine performs optimally, from generating the necessary force to ensuring stability during operation. Recognizing how these parts interact is vital for operators, as it directly impacts performance and ease of maintenance.

Core Elements of the Machinery

The core components of these machines typically include the motor, vibration system, and the base frame. The motor is responsible for driving the equipment, while the vibration system generates the necessary force to compact materials. The base frame ensures the stability of the entire structure, providing support during use. Each of these elements works in harmony to achieve maximum efficiency.

Maintenance and Troubleshooting

Regular maintenance is key to keeping the machinery in top shape. Understanding how each element functions allows operators to spot wear or damage early on. Routine checks of components such as the engine, hydraulic systems, and vibration mechanism can prevent costly repairs. Knowing how to troubleshoot common issues with these parts can significantly reduce downtime.

Key Parts and Their Functions in Compactors

Each machine is made up of essential components that work together to provide maximum efficiency. Understanding the function of these elements helps operators maintain proper performance and troubleshoot effectively. By knowing the purpose of each major part, it’s easier to ensure smooth operation and address potential issues promptly.

Engine and Power Transmission

The engine is the heart of the machine, supplying the power needed for operation. It drives the transmission system, which transfers energy to other components like the vibration mechanism. Regular maintenance of the engine ensures reliable performance and prevents unexpected breakdowns.

Vibration Mechanism

The vibration system is responsible for generating the force necessary to compact materials. It typically consists of a centrifugal force-driven mechanism that creates the intense vibrations needed to achieve compaction. This part must be checked regularly for wear, as its efficiency directly impacts the quality of the compaction.

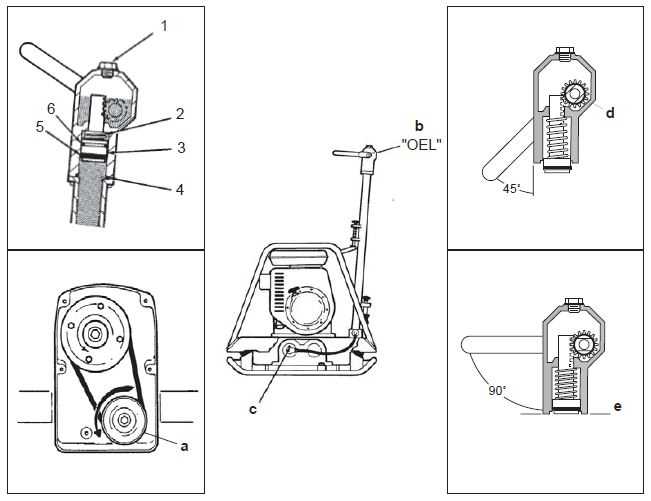

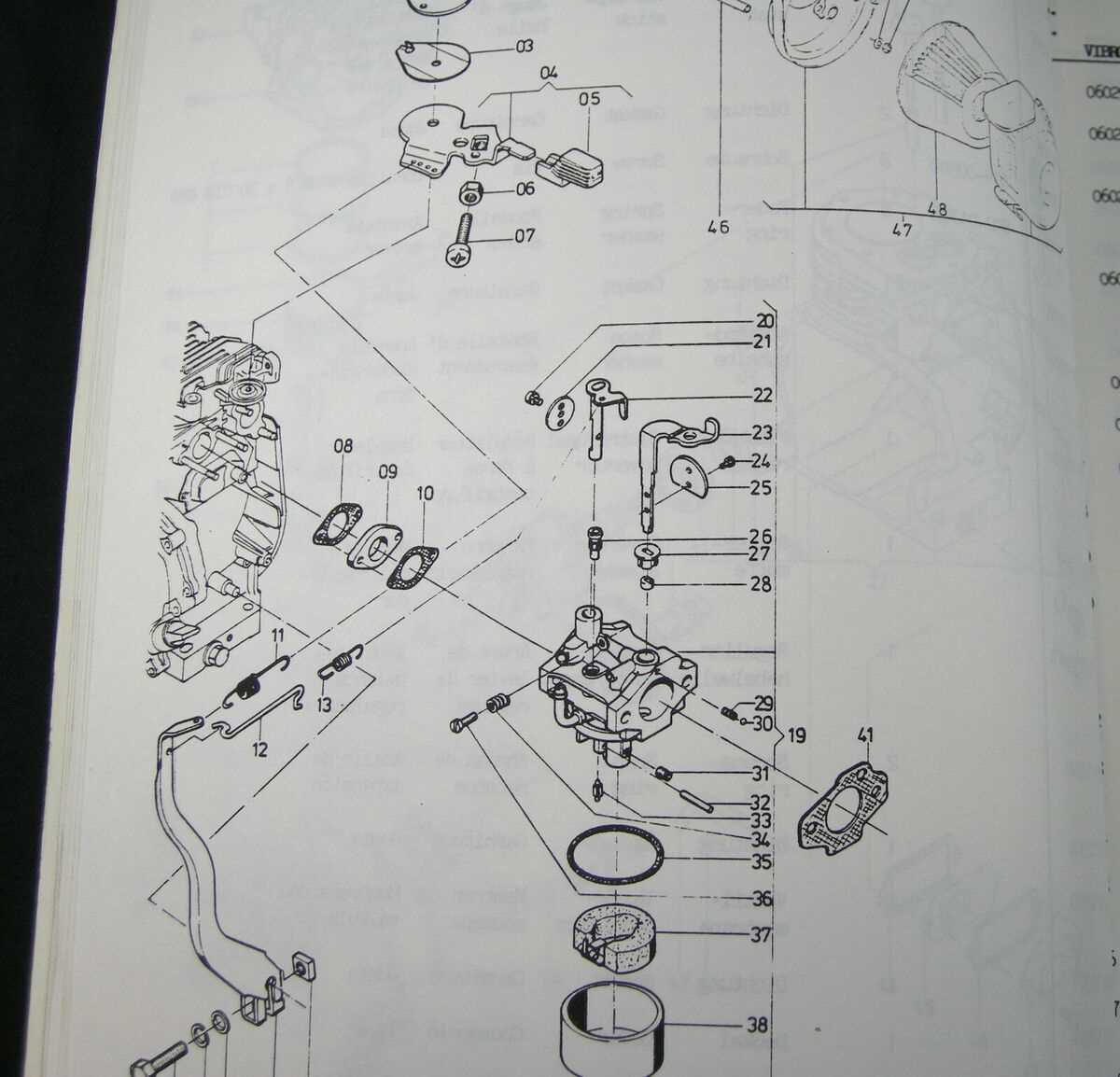

How to Identify Machine Components Easily

Identifying the various elements of any machinery is crucial for effective maintenance and troubleshooting. Being able to recognize each key component allows operators to quickly address issues and ensure smooth operation. This knowledge also helps in acquiring the correct replacement parts and accessories when needed.

Using the Manual and Labeling System

The first step in identifying machine elements is to refer to the user manual, which often includes a detailed layout of each component. Additionally, many manufacturers label important parts with identification numbers or tags. These labels can be found on the frame or near key sections of the machine, making it easier to locate specific parts for replacement or repair.

Visual Inspection and Common Features

Performing a thorough visual inspection of the machinery can also help in identifying its components. Look for recognizable features like the engine, control handles, and hydraulic systems. Each section typically has a unique appearance, such as a large motor or a distinctive vibration mechanism, which makes it easier to pinpoint during checks.