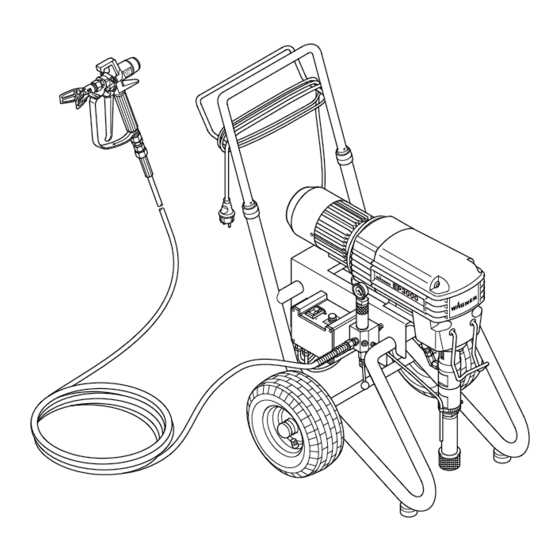

When working with spray machines, knowing how to identify and maintain each individual component is crucial for ensuring optimal performance. A detailed visual reference can be immensely helpful in navigating through the various sections of the machine, helping users to manage repairs and upkeep effectively. This section will provide essential information about the different elements of the system and their functionality.

Accurate identification of parts is vital for any repair or maintenance task. Without a clear view of how each part fits into the overall mechanism, it can be challenging to carry out even simple repairs. This guide will assist in understanding the layout and location of components that make up the equipment.

By understanding how each part works, users can ensure that their device remains in good working condition for longer periods. Whether you are replacing worn-out elements or just performing regular maintenance, a clear visual understanding of the internal setup will save time and effort.

Key Components of the Spray System

Understanding the essential elements of a spray machine is critical for efficient operation and maintenance. Each component plays a specific role in ensuring that the system functions properly. Recognizing the key parts within the mechanism allows users to troubleshoot issues and perform necessary repairs with ease.

The motor is one of the most important components, as it powers the entire system. It ensures that the flow of materials is consistent, providing the necessary force for the spraying process. A properly functioning motor is crucial for achieving smooth and even results during each use.

Hoses are another key element, responsible for directing the material to the spray nozzle. These flexible conduits need to be checked regularly for blockages or leaks, as they are critical to the overall performance of the machine. Without efficient hoses, the spray system cannot deliver consistent results.

Spray nozzle selection and maintenance are also crucial. The nozzle controls the flow and pattern of the material being applied. Different nozzle types can be used for various tasks, and keeping it clean and free from clogs ensures optimal spraying efficiency.

Understanding the Layout of the Component Map

To effectively maintain and repair equipment, it’s essential to have a clear visual representation of the internal components and their layout. A well-structured reference allows users to quickly identify individual parts, making the process of troubleshooting and fixing issues much simpler. A detailed layout ensures that every part can be located and accessed without confusion.

Each section of the visual reference corresponds to specific components within the system, organized for easy navigation. By following the layout, users can better understand how the parts are connected and interact with each other, which helps in identifying potential areas of concern.

Understanding this layout is especially helpful during repairs, as it provides a roadmap for disassembly and reassembly. It also highlights the order in which components should be checked or replaced, helping users work systematically and avoid overlooking essential elements.

How to Replace Components in the Spray System

Replacing faulty or worn-out components is an essential part of maintaining any spray machine. Properly replacing parts ensures the continued efficiency and longevity of the equipment. By following a systematic approach, users can easily swap out damaged elements without causing further issues.

First, it is important to turn off the machine and disconnect it from any power sources. Safety should always be the priority before performing any maintenance. Once the system is powered down, begin by identifying the component that needs replacement, based on the symptoms or the visual reference.

Next, carefully remove the old component, taking note of how it is installed. This will be helpful for installing the new part correctly. Be sure to inspect the surrounding areas for any signs of wear or damage that might affect the performance of the new component.

Finally, install the new part by following the reverse process. Ensure that all connections are secure and test the system after replacement to confirm that the issue has been resolved and the machine is functioning properly.