When maintaining or repairing grooming tools, it’s essential to have a clear understanding of how each part works and fits together. Having a visual reference can greatly simplify the process of identifying the right pieces and performing repairs. Whether you’re fixing a malfunctioning device or just conducting regular upkeep, knowing how to interpret the internal structure is crucial for success.

In this guide, we’ll explore the key elements of these tools, highlighting the most common components that may require attention. With the right information, you’ll be able to troubleshoot, replace worn-out parts, and extend the lifespan of your grooming equipment. Understanding these elements will give you more confidence in performing repairs on your own.

Understanding Clipper Components and Their Functions

When it comes to maintaining and repairing grooming tools, understanding the individual elements that make up the device is essential. Each component plays a specific role in ensuring smooth operation, and recognizing how they work together can help with troubleshooting and repairs. Knowing what each part does will allow you to identify issues more easily and replace faulty components efficiently.

The main components of these tools include the motor, cutting blades, and the casing that holds everything in place. These elements must function together seamlessly for the device to work properly. Regular maintenance of these parts, such as cleaning the blades or lubricating the motor, helps maintain optimal performance and prolong the life of your equipment.

Motors are at the heart of the device, providing the necessary power to move the blades. Over time, they can wear down and require maintenance or replacement. Cutting blades, which come in various shapes and sizes, need to be kept sharp and free from debris to ensure a smooth, effective cut. The housing, or external casing, protects the internal components from damage while providing a comfortable grip for the user.

By familiarizing yourself with these basic components, you’ll be better prepared to address any issues that arise and keep your tools functioning at their best. Regular inspection and upkeep of each element ensures long-term reliability and performance.

How to Read a Clipper Assembly Breakdown

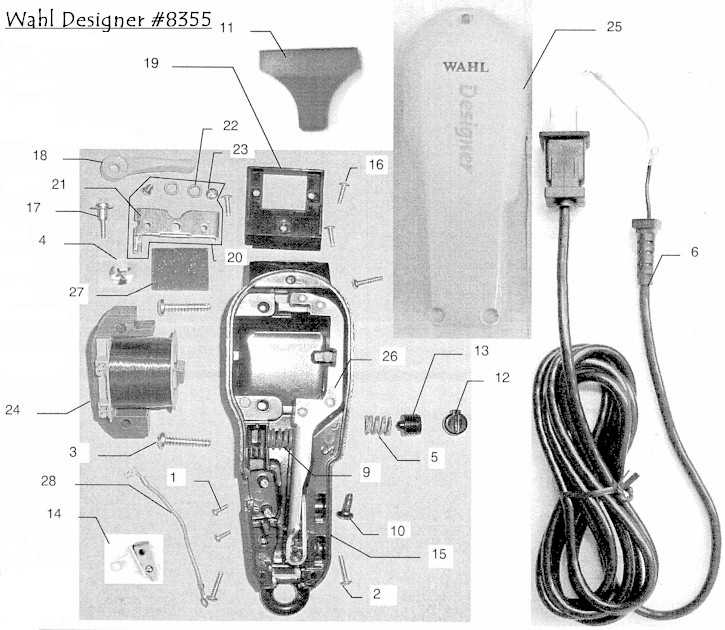

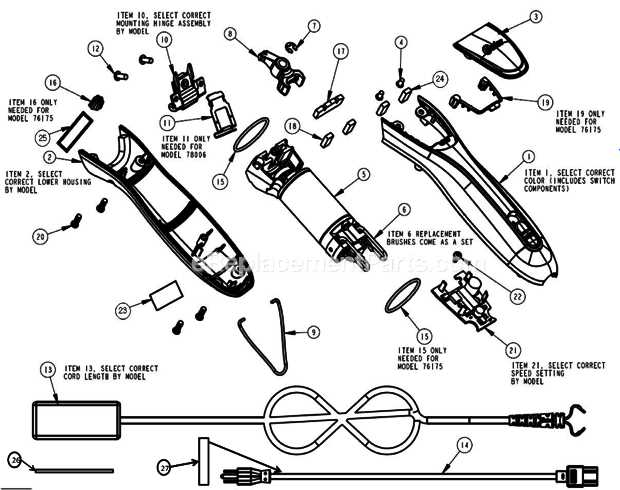

Interpreting a visual breakdown of your grooming tool’s components can significantly ease the repair or maintenance process. These illustrations offer a detailed view of each individual element, allowing you to pinpoint the exact pieces that need attention. Understanding how to read these images ensures you can accurately identify parts and locate their corresponding numbers or labels.

Typically, these visual references are organized with numbered or labeled components that correspond to a parts list. The diagram will show the positioning and orientation of the elements within the device, helping you understand how they interact. This makes it easier to see where each piece fits and what might need replacement or repair.

When viewing such a breakdown, start by locating the part in question within the image. The labels or numbers will guide you to the correct section in the accompanying list, where detailed information about that specific element will be available. This information may include the part number, material, and the proper way to assemble or disassemble it.

By carefully studying these illustrations, you’ll gain a better understanding of how each component functions within the tool, which can help you perform repairs more efficiently and accurately.

Common Repairs Using Clipper Assembly Breakdown

Repairs are often necessary to keep grooming tools in good working condition. With a clear understanding of the tool’s internal structure, you can easily identify common issues and take appropriate steps to resolve them. Visual guides help you pinpoint the components that need fixing or replacing, ensuring a smoother repair process.

One of the most common issues is a dull or damaged cutting blade. Over time, blades can lose their sharpness or become misaligned. By referring to a breakdown, you can easily locate the blades and assess whether they need sharpening or replacing. This will help restore the tool’s cutting performance.

Another frequent repair involves the motor. If the tool is not functioning properly, it may be due to motor wear or a loose connection. The breakdown will show you the motor’s placement and the necessary components to check, such as wires or gears, making it easier to identify the source of the issue.

Finally, external housing issues such as cracks or loose fittings are also common. These can often be repaired by replacing the casing or securing loose screws. Using the guide, you can quickly locate the relevant components and determine the correct replacement or adjustment.