Every refrigeration system consists of various elements working together to ensure proper functionality. Whether for commercial or industrial use, these systems rely on a precise arrangement of components to maintain the desired temperature. Understanding the layout of these elements is key to both effective troubleshooting and efficient operation.

By familiarizing yourself with the specific arrangement of key elements, you can easily identify where issues may arise. Each component has a role in maintaining the system’s performance, and knowing their positions helps streamline maintenance tasks and repairs. Proper knowledge of the system layout ensures quicker fixes and more reliable operation.

From compressors to evaporators, the intricate configuration of these elements allows them to perform optimally. With a clear understanding, you can enhance the overall efficiency and lifespan of the system, reducing downtime and improving cost-effectiveness in the long term. Knowing what each piece does and where it belongs is fundamental for anyone involved in managing or maintaining these systems.

Understanding Key Components of Refrigeration Systems

Refrigeration systems consist of several critical elements that work in unison to maintain a controlled environment. These components must be in perfect harmony to ensure that temperature and humidity levels remain consistent. The functionality of each part affects the overall performance, making it essential to understand how each one contributes to the system’s efficiency.

The key elements include the compressor, condenser, evaporator, and thermostat, each playing a specific role. The compressor is responsible for circulating refrigerant, while the condenser expels heat. The evaporator absorbs heat from the surroundings, and the thermostat maintains the desired temperature level. All these components are interconnected, and proper maintenance is crucial for optimal performance.

| Component | Function |

|---|---|

| Compressor | Circulates refrigerant through the system, increasing pressure and temperature. |

| Condenser | Releases heat from the refrigerant as it cools down, changing from gas to liquid. |

| Evaporator | Absorbs heat from the interior environment, cooling down the space. |

| Thermostat | Monitors and regulates temperature, ensuring that it remains constant. |

By understanding the roles of each element, operators can perform more effective diagnostics and maintenance. Whether performing routine checks or addressing an issue, knowing how each piece functions ensures that repairs can be made quickly and effectively, keeping the system running smoothly for extended periods.

Essential Parts for Efficient Cooling Systems

In order for refrigeration systems to operate at their best, several crucial components are needed to ensure optimal performance. These elements work together to regulate temperature, remove excess heat, and maintain an energy-efficient environment. Without each piece performing its designated role, the overall effectiveness of the system would be compromised.

Key Elements for Maintaining Efficiency

Each component plays a specific role, contributing to the smooth operation of the system. Below are the most important elements to consider for an efficient cooling setup:

- Compressor: The driving force behind refrigerant circulation, it compresses the refrigerant and sends it through the system.

- Condenser: Responsible for expelling heat from the refrigerant, ensuring it transitions from a gas to a liquid state.

- Evaporator: Absorbs heat from the interior environment, cooling the space to the desired temperature.

- Expansion Valve: Controls the flow of refrigerant into the evaporator, regulating the cooling process.

- Thermostat: Monitors and maintains the set temperature by controlling the entire system’s operation.

Ensuring Long-Term Performance

To keep the system running efficiently for years, it’s crucial to ensure that these components are properly maintained. Regular checks and timely repairs help to avoid system failures and ensure continuous optimal functioning. Additionally, understanding the importance of each part allows for better troubleshooting in case of any issues.

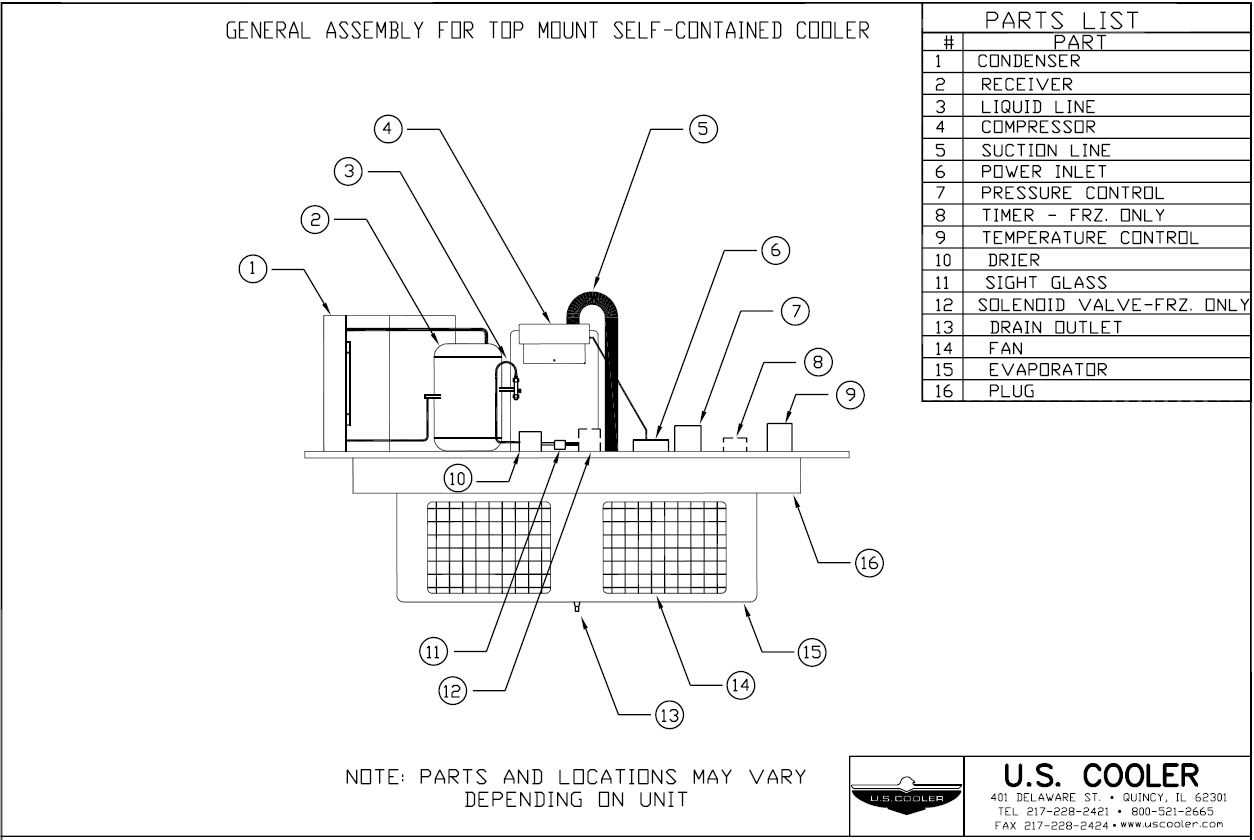

How to Read a Cooler Parts Diagram

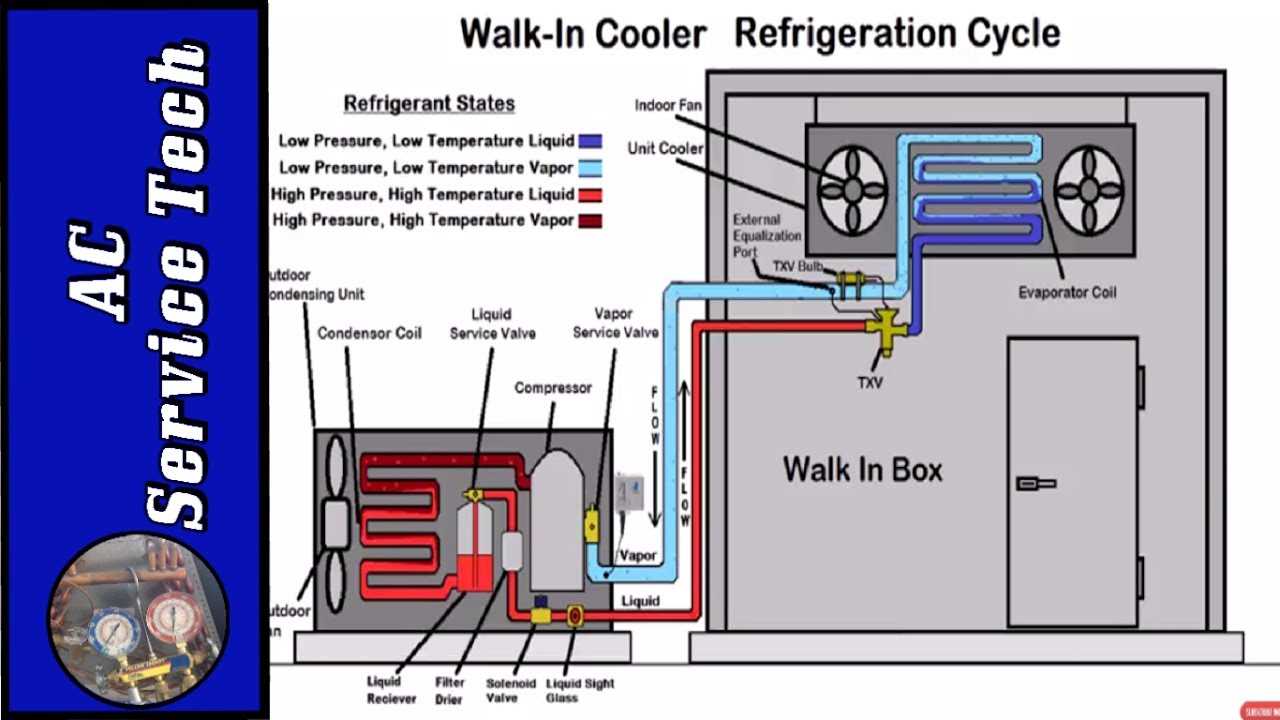

Understanding a system layout is essential for anyone involved in troubleshooting, repairs, or maintenance. These layouts provide a visual guide to the components within the system, illustrating how each part connects and functions together. Interpreting these visuals correctly helps you identify issues, locate specific elements, and understand their roles in the overall operation.

When reading a schematic, the first step is to familiarize yourself with the symbols used to represent different components. These symbols typically correspond to real-world parts like compressors, condensers, and thermostats. Pay close attention to the flow lines, which indicate how refrigerant or coolant moves throughout the system. This will help you trace the path and identify any potential blockages or faults.

Next, take note of the annotations on the schematic. These often provide valuable information such as part numbers, specifications, and connections. Understanding these details can simplify the process of finding the correct replacement components or making the necessary adjustments.

Finally, practice interpreting these visuals with real-world examples. By combining your understanding of the system layout with hands-on experience, you’ll be able to make informed decisions quickly, whether you’re performing maintenance or addressing a malfunction.

Identifying Components in a Walk in Cooler

Recognizing the individual elements within a refrigeration system is essential for proper maintenance and troubleshooting. Each component plays a unique role in ensuring the system operates efficiently, from regulating temperature to managing airflow. Being able to identify these pieces quickly allows for faster diagnostics and repairs.

Common components you’ll encounter include the compressor, which circulates refrigerant, and the evaporator, which absorbs heat. The condenser, located outside the system, expels heat to maintain the right balance. Understanding the location and function of each part helps to troubleshoot issues and prevent system failure.

Additionally, identifying auxiliary components such as fans, thermostats, and expansion valves is crucial. These smaller elements often work together with the primary components to ensure smooth operation and temperature control. Proper identification and understanding of each part will empower you to perform efficient repairs and maintenance.

Maintenance Tips for Cooler Parts

Proper upkeep of refrigeration systems is essential for ensuring their longevity and peak performance. Regular maintenance helps avoid unexpected breakdowns and maximizes the efficiency of each component. Understanding how to care for these elements can save both time and money in the long run.

Regular Inspections and Cleaning

One of the most effective ways to keep the system running smoothly is through routine inspections. Checking for signs of wear and tear, corrosion, or leaks can prevent larger issues from arising. Cleaning components like fans, coils, and filters is equally important. Dust and debris buildup can significantly affect the system’s efficiency, leading to energy waste and higher operational costs.

Timely Replacement of Worn Components

Components like seals, gaskets, and refrigerant lines naturally degrade over time. Replacing these parts before they fail can prevent costly repairs and downtime. Stay proactive by monitoring the condition of these elements during regular maintenance checks, and replace them as needed to keep the system operating efficiently.