Understanding the essential components of snow removal machinery is key to ensuring proper operation and efficient maintenance. Whether you’re a professional or a hobbyist, knowing how each element fits together allows for smoother handling and fewer repairs. By familiarizing yourself with the various components, you can optimize your system’s performance and tackle common issues effectively.

Each device includes a series of mechanisms that work in unison to provide powerful snow-clearing capabilities. From hydraulic systems to mounting structures, each piece plays a vital role. Recognizing how these components interconnect will help in troubleshooting and maintenance, ensuring the equipment stays in top condition throughout the winter season.

Regular inspection and understanding of these mechanical elements can also prevent unnecessary downtime. Whether you’re dealing with wear and tear or addressing more complex issues, a clear grasp of the equipment’s structure will make the job easier. This guide will help you navigate the intricacies of your snow-clearing setup, ensuring optimal functionality.

Understanding Snow Removal Equipment Components

Each snow clearing system relies on a variety of mechanisms working together to perform efficiently. From the frame to the hydraulics, each part has a specific function that contributes to the overall operation. Understanding how these components interact with one another is crucial for proper handling and maintenance.

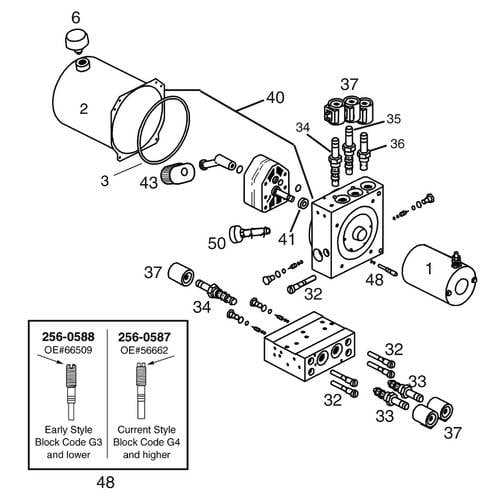

Key elements include the mounting structure, control systems, and power units, which all require proper care to function at their best. The hydraulic components are especially vital as they control the movement and adjustment of the clearing blade, ensuring smooth operation. Additionally, the wear-resistant components are designed to withstand harsh winter conditions, providing durability and longevity.

When familiar with the equipment’s structure and function, identifying issues becomes much easier. This knowledge helps in troubleshooting and ensures you can maintain peak performance throughout the winter season. Understanding the basics of each element empowers users to keep their equipment in optimal condition, ready for any challenge that comes their way.

How to Identify Snow Clearing Components Quickly

Efficiently identifying the components of your snow removal equipment can save valuable time when troubleshooting or performing maintenance. Understanding the function and appearance of each element helps you quickly pinpoint issues or make necessary adjustments. Recognizing the most common components and their specific roles ensures that you’re prepared to tackle any situation without confusion.

Familiarizing Yourself with Key Elements

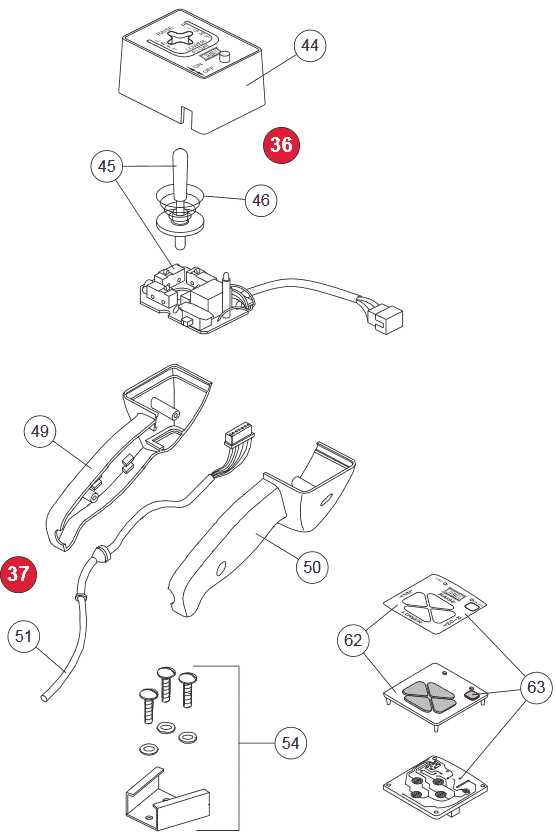

Start by becoming familiar with the major components, such as the frame, control systems, and hydraulic mechanisms. Each plays a distinct role in the operation of the system, and knowing their layout will allow you to identify them at a glance. For example, the hydraulic pump typically features specific connections and shapes that distinguish it from other parts like the mounting frame or the blade adjusters.

Use Visual Cues for Quick Identification

Pay attention to specific design features that are unique to each component. Most systems are designed with distinct visual markers that help users quickly recognize each part, whether it’s the color, shape, or size. Familiarizing yourself with these visual cues makes it easier to spot and assess issues, ensuring smooth operation and reducing repair times.

Common Issues with Snow Clearing Equipment

Snow removal machinery is designed to withstand harsh winter conditions, but it is still prone to certain issues over time. Understanding the most common problems can help prevent major failures and keep the system running smoothly. From mechanical wear to electrical malfunctions, identifying these issues early can save time and money on repairs.

Hydraulic System Failures

One of the most frequent issues involves the hydraulic system, which controls the movement of the clearing blade. Leaks or low fluid levels can cause poor performance or total failure. If the system is not functioning as expected, check for signs of fluid leakage or damaged hoses that could affect the system’s pressure and performance.

Electrical Component Malfunctions

Electrical failures can also lead to significant problems. Issues such as faulty connections, blown fuses, or damaged relays can disrupt control systems, making it difficult to adjust the blade or operate the equipment effectively. Regularly checking the wiring and connections helps identify any potential electrical problems before they become major issues.