Tractors are complex machines that require regular maintenance to operate efficiently. A thorough understanding of their mechanical layout is crucial for diagnosing issues and ensuring longevity. By familiarizing yourself with the different sections of the vehicle, you can quickly identify when something isn’t functioning properly and take the necessary steps for repair.

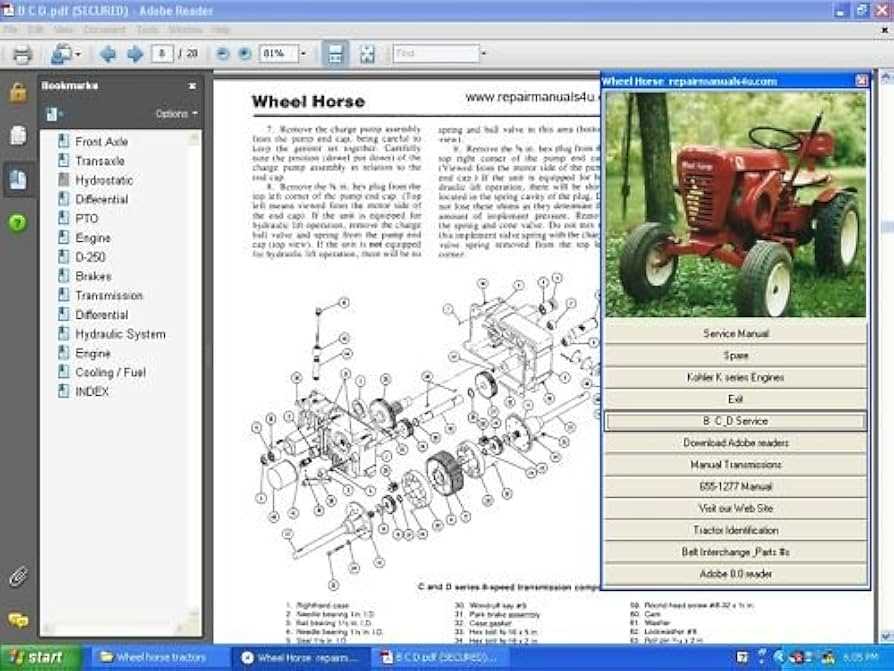

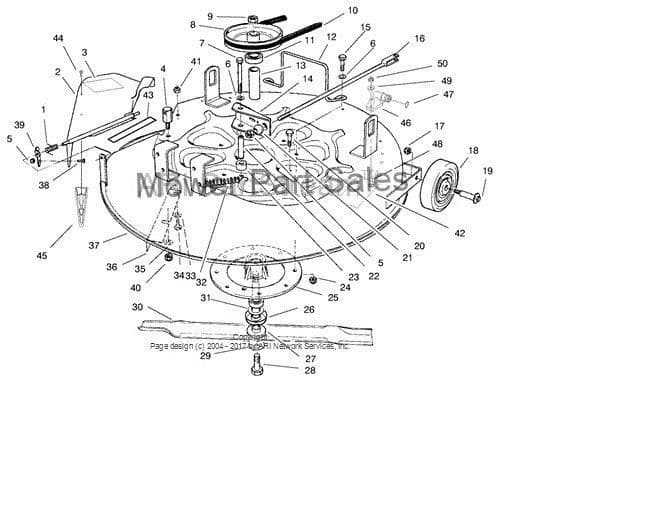

Visual guides are invaluable tools when it comes to understanding the intricate arrangement of components. They provide a clear representation of how each part fits together, helping both seasoned mechanics and novice users alike. Recognizing the role of each component within the whole system allows for more effective troubleshooting and maintenance.

Being able to recognize potential problems early can save time, reduce repair costs, and extend the lifespan of your equipment. In this guide, we will explore how to interpret such reference materials, highlighting key areas that require attention and offering practical tips on maintaining them for optimal performance.

Understanding Tractor Components

Knowing the layout of the key mechanical elements in a tractor is essential for proper maintenance and troubleshooting. The efficiency of these machines depends on the smooth interaction between various internal systems, such as the engine, transmission, and power steering. A clear understanding of how each component functions can make diagnosing problems quicker and more effective.

The primary components are organized into several categories, each with its specific role. By focusing on these categories, operators can gain a deeper understanding of how each part contributes to the overall performance of the machine. Regular inspection and maintenance are necessary to keep everything running smoothly.

| Component | Description | Function |

|---|---|---|

| Engine | The heart of the machine | Provides power for movement and operation |

| Transmission | The system that transmits power from the engine | Controls speed and torque |

| Hydraulic System | System of pumps and valves | Operates lifting and steering mechanisms |

| Chassis | The frame of the vehicle | Supports all mechanical components |

| Braking System | Consists of brake pads and fluid | Ensures safe stopping |

Essential Parts for Maintenance and Repair

Proper upkeep of machinery is critical to ensuring its longevity and optimal performance. Knowing the key components that require regular attention allows for smoother operation and reduces the risk of unexpected breakdowns. These critical systems should be inspected routinely to identify any signs of wear or malfunction, facilitating timely repairs and minimizing downtime.

Key Components to Monitor

Some of the most essential elements to focus on include the engine, transmission, and hydraulic systems. Regular checks of these components ensure they function efficiently, and any issues can be addressed before they lead to more severe damage. Keeping a close eye on these systems helps prevent expensive repairs down the line.

Preventative Maintenance Practices

Regularly cleaning, lubricating, and adjusting vital systems are crucial actions in maintaining the health of the machine. Ensuring the engine remains well-oiled and the transmission fluid is at the correct levels can help avoid unnecessary strain. Additionally, checking for loose parts or worn seals is essential in maintaining a reliable and efficient operation.

Exploring the Tractor Component Layout

Understanding the layout of a machine’s internal systems is crucial for anyone working with mechanical equipment. A visual representation of these systems helps users see how each part connects and functions together. By breaking down the machine’s structure, these guides provide valuable insights into the assembly and make it easier to diagnose issues or plan maintenance tasks.

These reference materials often highlight critical sections such as the engine, transmission, and electrical systems, showing how each component interacts within the vehicle. Being able to identify specific elements within the layout aids in performing repairs more efficiently and effectively, ensuring that nothing is overlooked during maintenance or troubleshooting.

How to Read and Use the Diagram

Interpreting a visual representation of a machine’s components is essential for effective maintenance and repair. These guides provide a structured view of the system’s parts and their relationships, enabling users to easily identify and locate each element. Understanding how to read such visuals ensures that the correct steps are followed during repairs or adjustments, reducing the likelihood of errors.

Key Steps to Interpret the Guide

- Start by identifying the main sections of the layout. These often include the engine, transmission, and various subsystems.

- Look for labels that indicate the function of each component to understand how each part contributes to the overall operation.

- Pay attention to symbols or color coding that represent specific systems or the condition of each part.

Using the Visual Representation for Repairs

- Locate the problematic component in the guide to understand its connections and dependencies.

- Compare the layout with the actual machine to confirm the placement and condition of the part.

- Use the diagram to check for signs of wear or damage, and replace or repair components as needed.

Common Component Replacements

Over time, certain parts of a machine will inevitably wear out and require replacement. Regular maintenance can help extend the lifespan of the equipment, but some elements are subject to more frequent deterioration due to their regular use. Understanding which components are most commonly replaced allows for quicker, more effective repairs and ensures the continued smooth operation of the vehicle.

Frequently Replaced Parts

- Belts: These often wear down due to constant friction and need periodic replacement to prevent slipping or breaking.

- Filters: Air and fuel filters can clog over time, reducing efficiency and performance, requiring regular changes.

- Seals and Gaskets: These parts can degrade due to exposure to heat, oil, and pressure, leading to leaks or decreased efficiency.

- Batteries: Due to their limited lifespan, batteries typically need replacement after a few years of use.

Signs That Indicate Part Replacement

- Unusual noises such as squealing, grinding, or rattling often indicate worn-out belts or damaged components.

- Reduced engine performance or difficulty starting the machine may point to issues with filters or the battery.

- Leaks of fluid around seals and gaskets may signal the need for replacements to maintain proper pressure and prevent damage.