Every vehicle relies on a cleaning mechanism to maintain clear visibility during adverse weather conditions. This system consists of various interconnected components that work together to clear the surface of rain, snow, and debris. Understanding how these parts interact ensures proper maintenance and troubleshooting when issues arise.

Each component plays a specific role in the overall operation, from the motion of the cleaning arms to the mechanism that drives them. Knowing how these elements are arranged and connected helps in diagnosing faults and performing repairs. Whether you are dealing with a malfunction or simply seeking a deeper understanding of your vehicle’s operation, having a clear overview of this system is essential.

In this section, we will explore the different elements of the system, how they function together, and how to identify potential issues. By the end, you’ll have a better grasp of the intricate design that makes the system effective at clearing your vehicle’s surface.

The Functionality Behind the Cleaning System

In every vehicle, the mechanism responsible for clearing the front glass is made up of several components that work in harmony. This system ensures that the surface stays clean and free from obstructions, improving visibility and safety. The key to its operation lies in how these interconnected elements move together to efficiently perform their task, especially during adverse weather conditions. Understanding this movement is crucial for both repair and optimization of the system.

How the Mechanism Works

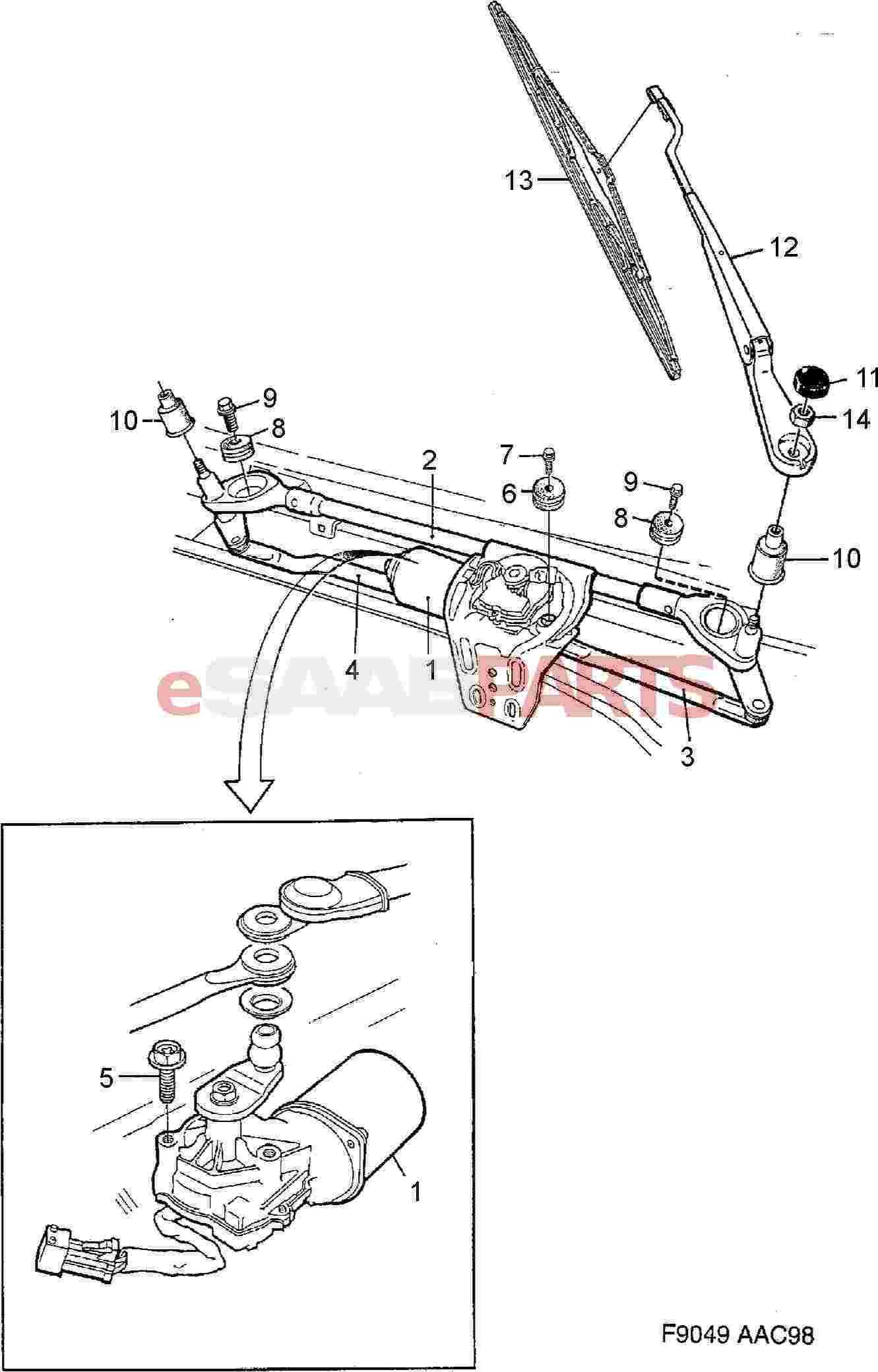

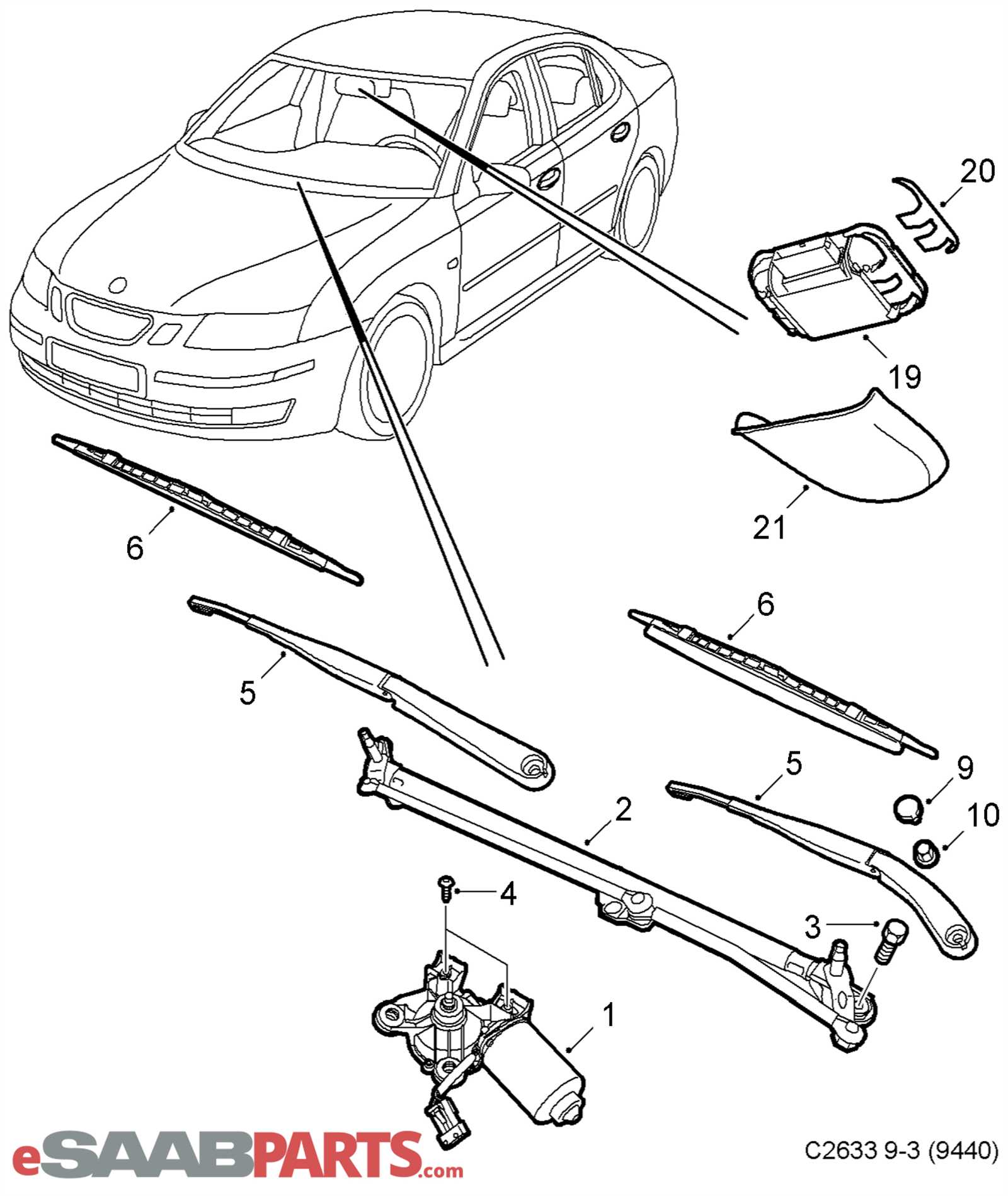

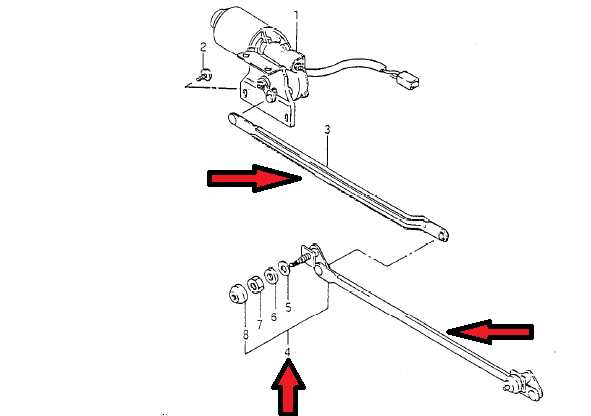

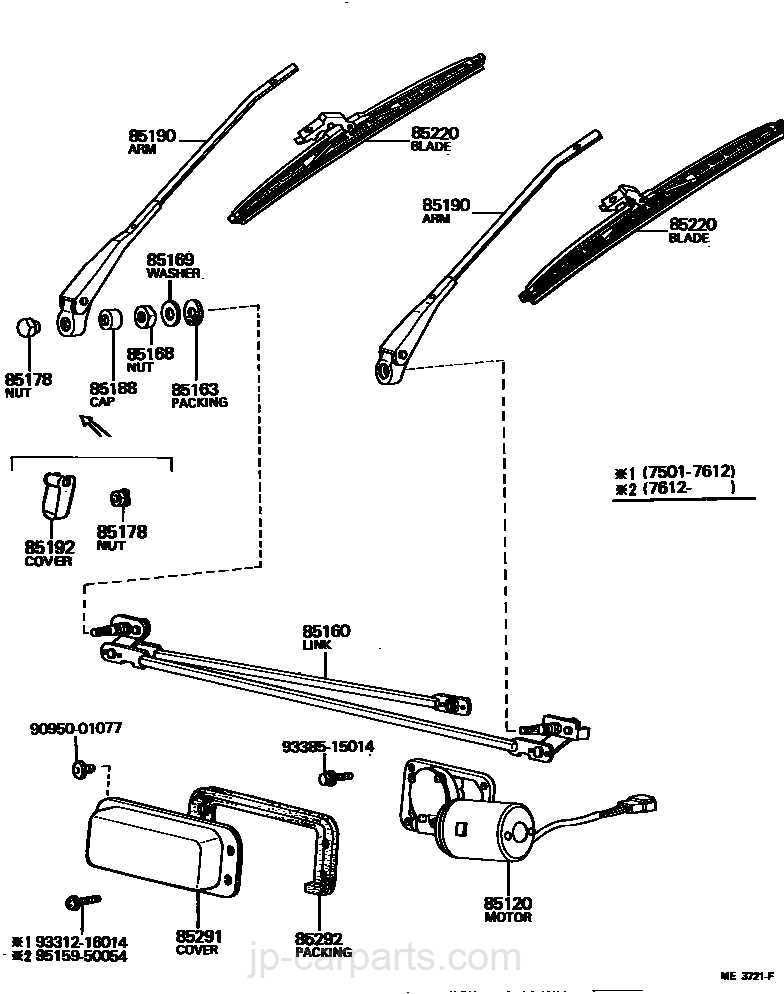

The central component that drives the entire system is the motor, which provides the force needed to initiate motion. This force is transmitted through various mechanical connectors, which translate the motor’s energy into movement, causing the cleaning arms to traverse the glass. The way these connectors interact determines the cleaning pattern and coverage, ensuring that no area is left untouched. The design of these components is specifically tailored to provide smooth and reliable performance under various conditions.

Common Issues and Maintenance Tips

Over time, wear and tear can affect the efficiency of the system. Components may become loose, corroded, or misaligned, leading to poor operation. Identifying these issues early on can prevent more significant problems and ensure that the system continues to perform effectively. Regular checks of the moving parts, as well as proper lubrication and cleaning, are essential maintenance practices that can prolong the life of the system. Keeping an eye on these aspects helps avoid unnecessary repairs and ensures optimal functioning.

Key Parts of Windshield Wiper Mechanism

The cleaning system of a vehicle consists of several crucial components that ensure the smooth operation of the glass-clearing function. These elements work in sync to remove rain, snow, and debris from the surface, allowing for clear visibility. Each part plays a distinct role in driving the system’s functionality, and understanding their interaction is essential for proper maintenance and troubleshooting.

Primary Components Involved

The motor is the starting point for any movement within the system, as it generates the power needed to initiate action. The motor is connected to a series of rods and connectors that translate its rotational energy into linear motion. This motion is then transferred to the cleaning arms, which move across the surface. The blades attached to these arms are responsible for physically clearing the glass, ensuring that no residue is left behind. The coordination between these components ensures effective and continuous cleaning performance.

Auxiliary Elements for Functionality

Additional components, such as the control switch and relay system, are essential for managing the operation of the entire mechanism. The switch allows the driver to control the cleaning process, while relays ensure that the motor receives the correct power at the right time. Some systems also feature a sensor that detects rain and automatically activates the mechanism when needed. These auxiliary elements contribute to the overall efficiency and responsiveness of the system, making it adaptable to different driving conditions.

How to Read Wiper System Diagrams

Understanding technical illustrations is essential when diagnosing and repairing vehicle cleaning systems. These visual guides provide a detailed layout of the entire mechanism, showing how each component interacts with the others. By learning how to read these illustrations, you can effectively troubleshoot issues, identify parts, and perform maintenance more accurately.

Identifying Symbols and Notations

Most technical diagrams use specific symbols and notations to represent various components and their functions. Familiarizing yourself with these symbols will make it easier to understand the overall structure. For example, arrows often indicate motion, while lines represent connections between components. Different line styles can signify electrical connections or mechanical links. Understanding these conventions will allow you to interpret the diagram correctly and spot potential issues.

Understanding Component Layouts and Flow

The layout of the diagram is usually arranged to show the flow of motion or electrical signals from one part to another. Following the path of energy or movement helps you understand how the system operates. By tracing the connections from the control switch to the motor or from the motor to the arms, you can see how each element contributes to the cleaning function. These diagrams often show the sequence of operations, allowing you to pinpoint where problems might arise in the flow of the system.