When maintaining or repairing machinery, having a clear visual representation of its individual components is essential. Knowing how each part fits together allows for more efficient troubleshooting and ensures that repairs are done correctly. A well-organized guide can save time and help avoid costly mistakes during maintenance tasks.

For anyone working with complex equipment, a visual breakdown of its elements is invaluable. These guides typically include labeled images, showing where specific components are located and how they interact with other parts. Understanding this layout is crucial for anyone looking to perform repairs or upgrades with confidence.

In this article, we’ll explore how to interpret such guides, identify common parts, and ensure proper care and handling. With the right knowledge, anyone can maintain their machinery in optimal condition for longer-lasting performance.

Understanding the Z445 Parts Layout

Proper maintenance and repair of machinery depend largely on having a clear understanding of how each individual component is arranged and functions. By visualizing the arrangement, users can quickly identify any malfunctioning or damaged areas, making it easier to perform necessary repairs. Knowing how parts are distributed and connected ensures a more efficient repair process and extends the life of the equipment.

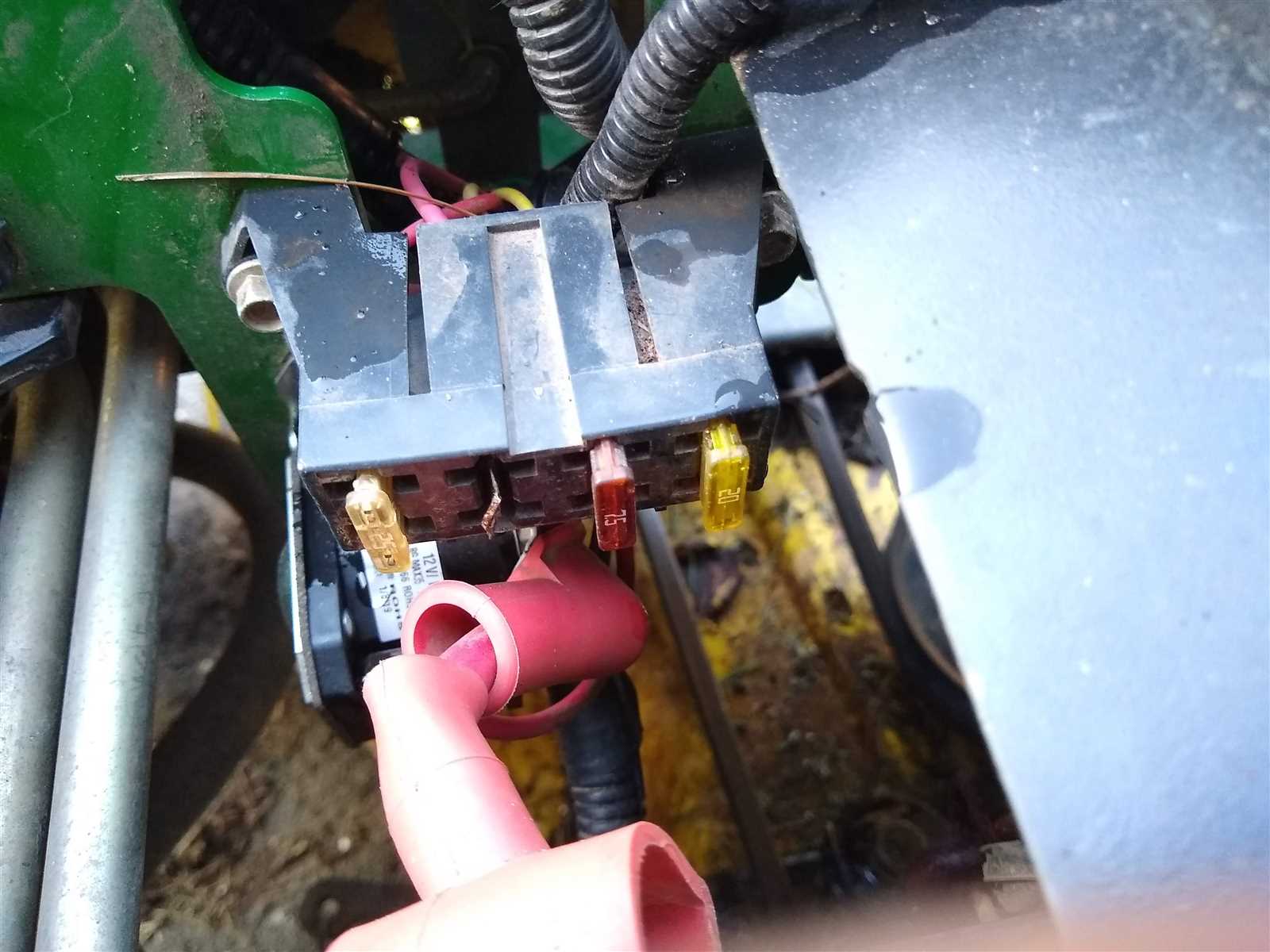

Component Overview and Functionality

The layout of any complex machine usually includes an organized presentation of the major elements that work together to keep the system functioning smoothly. These elements range from small connectors to larger mechanical parts, each serving a specific purpose. Understanding their roles within the system helps in recognizing potential issues and addressing them appropriately before they escalate into more serious problems.

Interconnectivity and Maintenance Efficiency

One of the key aspects of understanding how machinery operates is recognizing how individual elements interact. Many components are interdependent, so knowing where each piece fits and how it affects others allows for better troubleshooting. The clearer the layout, the easier it becomes to spot worn-out components or misalignments, reducing downtime and preventing unnecessary repairs.

How to Read the Z445 Parts Diagram

Understanding a visual representation of machine components is crucial for successful repair and maintenance. These guides typically include detailed images that show the location and connection of various elements, allowing users to identify specific parts quickly. Learning how to interpret these visuals makes troubleshooting much simpler and ensures accuracy when performing repairs or replacements.

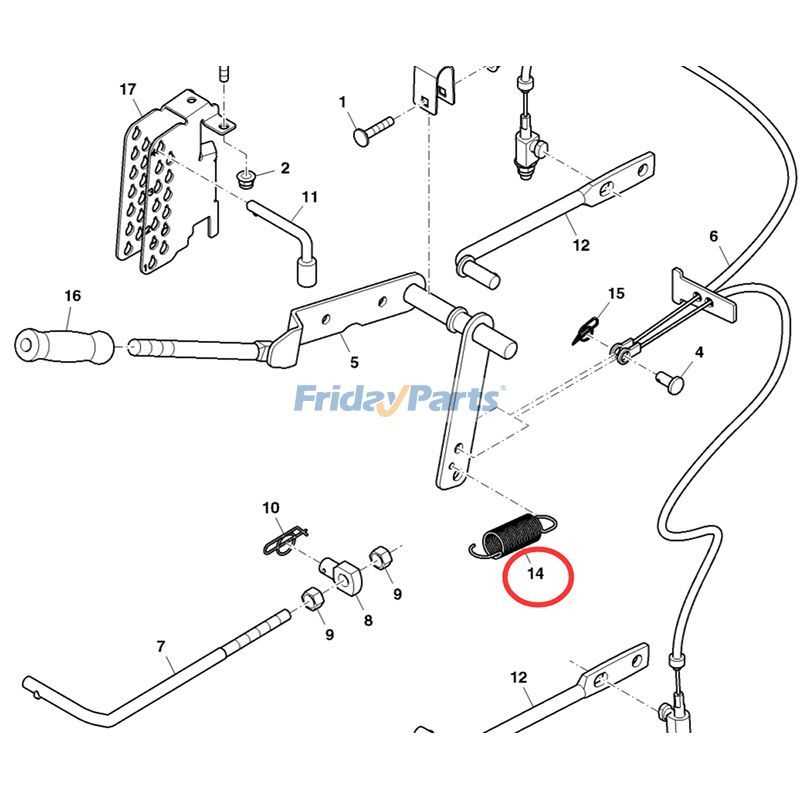

Identify Key Sections and Labels

Each visual guide is usually divided into sections, each focusing on a particular part of the machine. The first step is to identify these sections and the corresponding labels. These labels are often accompanied by numbers or codes, which correlate with part names or specifications. Being familiar with these identifiers helps in locating the correct components when repairs are needed.

Follow Component Connections and Groupings

Another important aspect of reading these visuals is understanding how different elements are connected. Parts often work together in systems, so it’s vital to note how each piece interacts with others. This interconnectivity will help in recognizing the cause of a malfunction and making the necessary adjustments or replacements efficiently.

Common Z445 Parts and Their Functions

Every machine is made up of numerous elements that work together to ensure smooth operation. Some components are essential for the basic functioning of the system, while others enhance performance or safety. Understanding the role of these key parts helps with routine maintenance and can make repairs easier when something goes wrong.

Engine and Drive Components

The engine is one of the most critical elements in any piece of machinery. It provides the power necessary for operation. Along with the engine, the drive components, such as belts and pulleys, transmit power to the wheels or other moving parts. Regular checks of these elements can prevent power loss or mechanical failure.

Control Mechanisms and Linkages

Control mechanisms, such as levers and pedals, allow the operator to manage the various functions of the machine. These parts are connected by linkages that translate the operator’s actions into specific movements. Ensuring that these connections are well-maintained is vital for smooth, responsive control during operation.