Maintaining the smooth operation of your lawn mower requires a good understanding of its mechanical system. From the drive mechanism to the wheel alignment, each part plays a crucial role in ensuring proper functionality. This guide provides insights into the various elements that contribute to the machine’s maneuverability, offering clarity on their structure and maintenance.

Having a clear view of how these elements interact with each other will help you identify any issues that may arise. Whether you are replacing worn-out parts or simply looking for maintenance tips, knowing the layout and function of each component is vital. Proper care can extend the lifespan of your mower and improve its performance.

By following a well-structured approach, you can ensure that all moving parts are in top condition, enhancing your mowing experience. Regular checkups and repairs are key to preventing unexpected malfunctions during use.

Steering System Overview

The control mechanism of a lawn mower is crucial for ensuring precise movement and maneuverability. A well-maintained system allows for smooth navigation, making it easier to handle even the most challenging terrains. This section provides an overview of how different components work together to give you better control over your equipment.

Key Components of the Control Mechanism

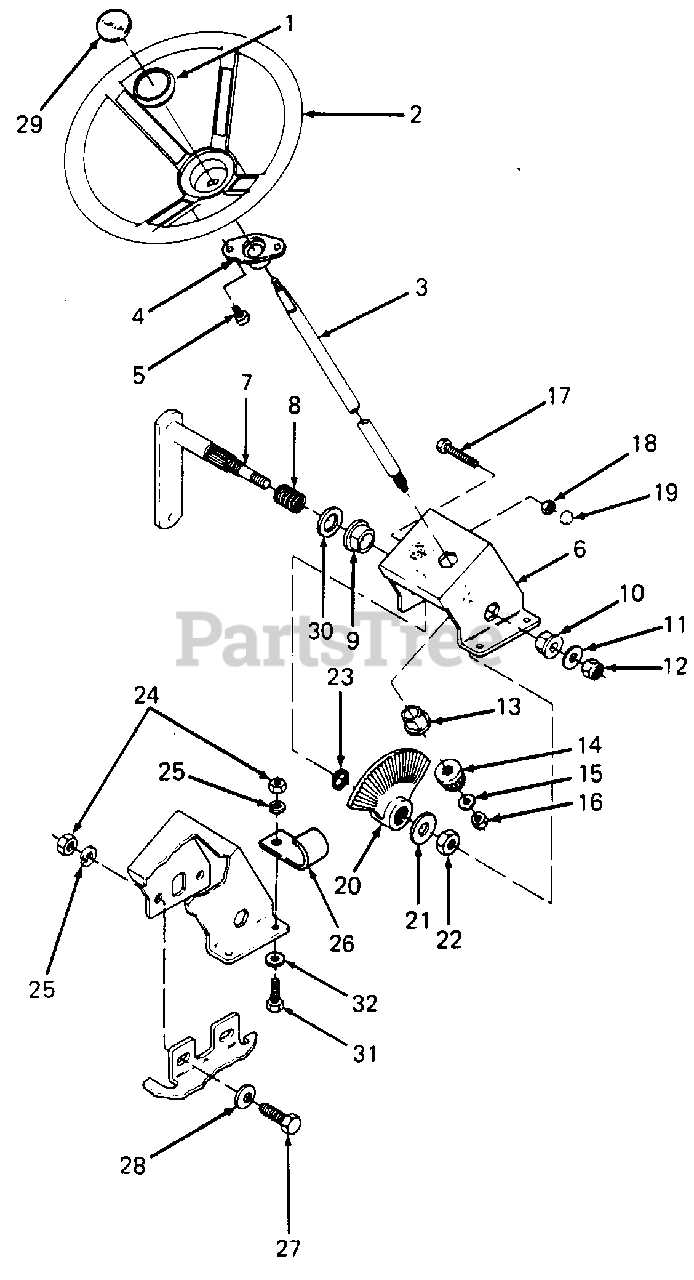

The main elements that make up this system include the wheel assembly, linkage rods, and the central control lever. Each component has a specific function that contributes to the overall performance of the device. The wheel assembly allows for directional changes, while the linkage rods connect to the control lever, enabling the operator to adjust the mower’s movement.

Maintaining the System for Optimal Performance

To keep the machine functioning properly, regular maintenance is essential. Checking for wear and tear, lubricating moving parts, and ensuring that all connections are tight will help prevent malfunctions. Routine inspections allow you to detect minor issues before they develop into more significant problems, ensuring a smooth experience every time you use the mower.

Identifying Key Control Components

Understanding the essential components that control movement and direction is vital for maintaining your lawn mower’s efficiency. These elements work in unison to allow precise handling and smooth operation. Identifying these components helps in diagnosing issues and performing accurate repairs when needed.

Essential Components for Directional Control

The central components that facilitate movement include the wheel assemblies, pivot points, and linkages. The wheel assemblies are responsible for turning the mower, while the pivot points allow for smooth movement, enabling precise adjustments. The linkages connect various parts, transmitting the operator’s input into the desired movement.

How to Spot Wear and Tear

Recognizing signs of damage in these components is essential for effective maintenance. Worn-out wheels or loose linkages can affect performance, leading to difficulty in maneuvering. Regularly inspecting these parts for cracks, rust, or looseness ensures that they continue to function correctly, maintaining the overall efficiency of the system.

How to Maintain Your Control Components

Proper upkeep of the control system ensures that all moving parts continue to function smoothly and efficiently. Regular maintenance helps prevent unexpected breakdowns and extends the lifespan of your equipment. By taking a proactive approach, you can avoid costly repairs and ensure optimal performance for longer periods.

Routine Inspections and Lubrication

Start by inspecting the key components for any signs of wear, such as cracks, rust, or excessive friction. Lubricating the moving elements, such as joints and linkages, helps reduce friction and ensures smooth operation. Using the appropriate grease or oil will prevent parts from seizing and contribute to overall system longevity.

Replacing Worn Components

Over time, certain parts will naturally wear out due to constant use. It’s important to replace components such as the wheels, linkages, or control rods once they show significant signs of damage. Keeping spare parts on hand and replacing them as needed can help maintain the performance and safety of your equipment.