Understanding the individual components of a chainsaw is essential for proper care and smooth operation. A detailed breakdown of the internal and external parts can greatly simplify the repair and maintenance process. By knowing the structure and function of each element, users can ensure their equipment stays in optimal condition for years to come.

Effective maintenance requires more than just knowing how to assemble or disassemble a chainsaw. It’s about identifying potential problems, locating the correct replacements, and understanding the role of each part in overall functionality. Proper care can prevent common malfunctions and extend the lifespan of your tool.

Detailed diagrams of these machines serve as an invaluable resource, helping users identify where each component fits and how to handle them. Whether you are troubleshooting an issue or performing routine upkeep, having this visual reference can make all the difference.

Understanding the Chainsaw Components

Every chainsaw is made up of several key elements, each with its specific function. Understanding how these components work together ensures that your tool operates efficiently and can be easily repaired when needed. From the engine to the cutting mechanism, each part plays a vital role in the overall performance of the machine.

The motor is the heart of the machine, providing the power needed for operation. It is connected to a series of smaller components, such as the fuel system, ignition system, and exhaust, which ensure that the chainsaw runs smoothly. The drive system, consisting of the clutch and sprocket, transfers power to the chain, enabling the cutting action.

Other elements, like the bar, chain, and tensioning system, work together to guide the chain and maintain proper tension during use. Each of these components must be maintained and replaced when necessary to ensure that the chainsaw continues to function safely and effectively. Understanding the relationship between these parts will help you identify potential issues early on and take appropriate action.

How to Use the Assembly Breakdown

When dealing with complex machinery, having a clear visual reference of its internal structure is essential. An assembly breakdown helps users understand how different components fit together and how to correctly identify each element for maintenance or repair. This visual guide is particularly helpful when troubleshooting issues or replacing specific components.

To use this reference effectively, start by familiarizing yourself with the layout of the machine. Each section will often be labeled with specific numbers or names that correspond to the various components. By matching these labels to the actual parts, you can easily locate the right piece during repairs. Understanding the orientation of the components can also help in reassembling the tool after maintenance.

When performing repairs or replacements, use the assembly guide to identify worn or damaged components. This step-by-step visual guide will save time by providing a direct reference, ensuring you don’t miss any important parts during the repair process. Having this breakdown handy can significantly reduce the complexity of the task and lead to more efficient maintenance.

Common Issues and Replacement Components

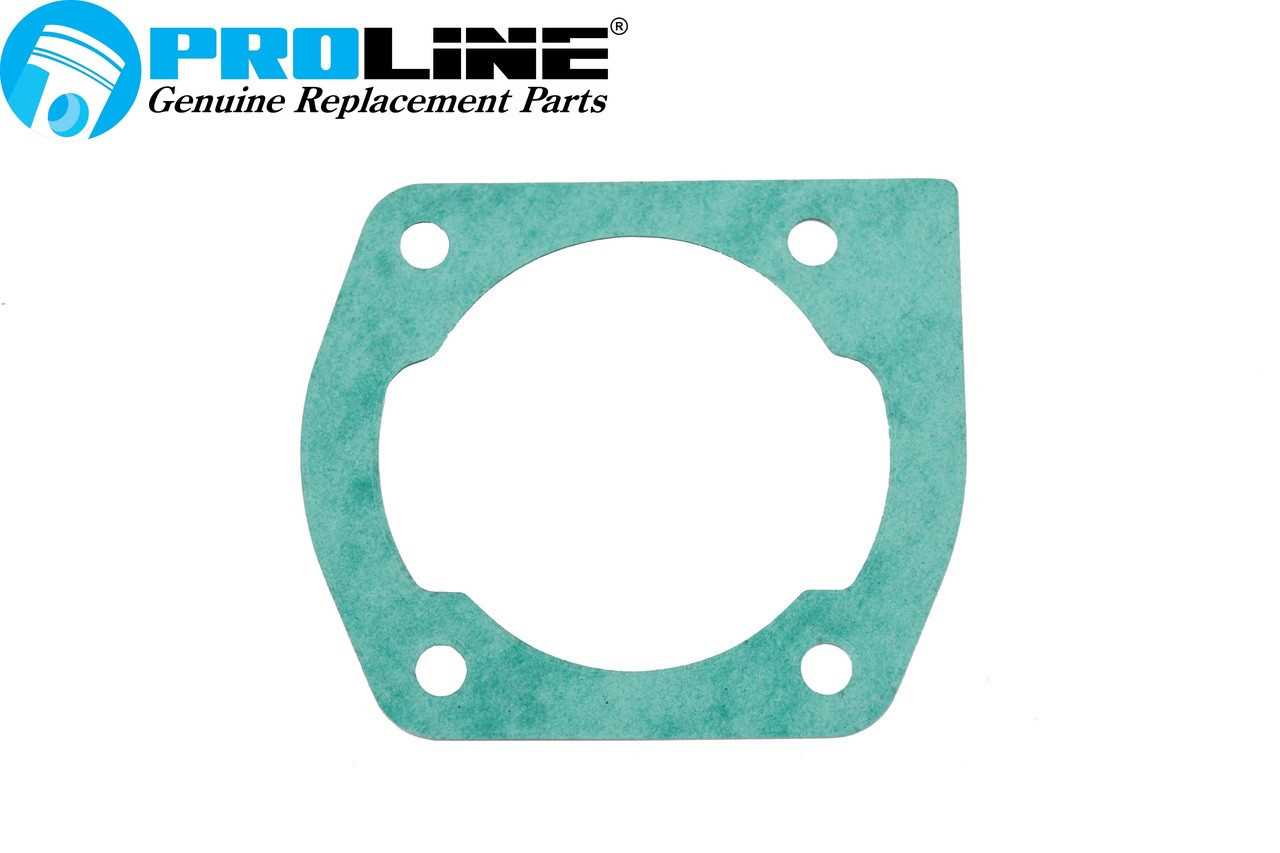

Over time, any mechanical tool will experience wear and tear. Understanding the most frequent problems that arise and knowing which components may need replacement is crucial for maintaining the equipment in peak condition. Identifying issues early can help prevent further damage and extend the lifespan of your tool.

One common issue is the failure of the cutting chain to operate smoothly, often caused by a worn sprocket or a damaged chain. Another frequent problem is the engine not starting, which can be due to issues with the ignition system or a clogged fuel filter. Replacing worn components promptly can save time and money in the long run by preventing more extensive damage.

Other parts, like air filters or fuel lines, may also need to be replaced periodically to ensure optimal performance. Having a clear understanding of which parts are prone to failure and knowing how to replace them will allow you to maintain your tool more effectively, ensuring it continues to perform at its best for years.