When it comes to maintaining a powerful cutting tool, knowing the key components and their functions is essential. Proper identification of each part ensures smoother operation and longevity. This guide will help you familiarize yourself with the different sections of your tool and provide useful information for efficient upkeep.

Understanding how each part works is crucial for anyone looking to perform routine repairs or replacements. Recognizing common issues before they become serious problems can save time and reduce repair costs. With a clear understanding of how everything fits together, you’ll be well-equipped to handle maintenance tasks independently.

By the end of this guide, you will be able to easily pinpoint which components need attention and know how to replace them correctly. Whether you’re dealing with wear and tear or preparing for a complete overhaul, this reference will support your efforts in keeping your tool in top shape.

Understanding Chainsaw Components

Proper knowledge of the essential elements that make up a cutting tool is key to maintaining its performance. Each section has a distinct role that contributes to the overall functionality, and understanding these can help ensure that the machine operates smoothly. Recognizing the individual components is the first step in keeping your equipment in peak condition.

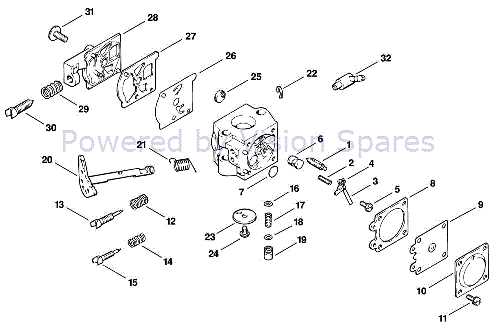

The various sections of the tool work together to enable effective operation. Key pieces include the power source, safety features, and the mechanisms that transfer energy to the cutting system. Knowing where each component is located and how it interacts with others allows for easier troubleshooting and more efficient maintenance.

With a clear understanding of the tool’s internal structure, you’ll be better prepared to identify which parts require attention, whether it’s due to wear, damage, or necessary upgrades. Proper care and regular inspection can significantly prolong the life of your equipment, ensuring it continues to function at its best.

Identifying Key Components for Maintenance

To maintain optimal performance, it’s crucial to recognize the primary elements that require regular attention. Some sections are more prone to wear due to frequent use, while others may need occasional inspection to ensure smooth operation. Knowing where to focus your efforts can help prevent major issues before they arise.

Engine components, such as the spark plug, fuel system, and air filter, play a vital role in starting and running the equipment effectively. Regular checks and replacements in these areas will ensure reliable operation and prevent unnecessary strain on the motor.

Safety features, including the handlebar and brake mechanisms, must also be monitored closely. These components are essential for safe handling and should be examined for any signs of wear or malfunction. Ensuring these parts are intact helps protect both the user and the equipment.

By identifying these critical components and understanding their function, you can perform more efficient maintenance, extending the tool’s lifespan and maintaining its efficiency for years to come.

Step-by-Step Guide for Replacing Components

When it’s time to replace worn or damaged elements of your tool, following a clear process ensures that the task is completed correctly. This guide will walk you through each necessary step to help you restore functionality and prevent further issues. Proper replacement of components can improve performance and increase the longevity of the equipment.

Preparing for Replacement

Before starting any replacement task, ensure that you have the right tools and replacement components. Gather all the necessary items, including wrenches, screwdrivers, and the new parts. It’s also important to disconnect any power sources to avoid accidents during the process. Carefully consult the user manual to familiarize yourself with the steps and identify the components that need to be replaced.

Replacing the Components

Once the equipment is powered down and you’ve located the components to be replaced, begin by removing any covers or housing that may be in the way. Follow the manufacturer’s instructions to carefully remove the old parts and install the new ones. Make sure each component is securely attached and properly aligned before reassembling the tool. After replacing, perform a brief check to confirm that everything is functioning as expected.

How to Repair Your Equipment

Repairing your tool can seem like a daunting task, but with the right approach and understanding of the problem, it becomes much more manageable. This section will guide you through common repair procedures, helping you address any issues and restore your tool to full functionality. Proper troubleshooting and timely repairs are essential for maintaining optimal performance.

Identifying the Problem

The first step in any repair is identifying the root cause of the issue. Carefully inspect the tool for any visible damage, unusual sounds, or performance issues. Often, problems are caused by clogged filters, faulty connections, or worn components. By pinpointing the source of the malfunction, you can determine whether it requires a simple fix or if more extensive repairs are needed.

Performing the Repair

Once you’ve identified the issue, gather the necessary tools and replacement parts. Begin by following safety precautions, such as disconnecting the power source. If you need to replace or clean components, carefully remove the damaged parts and install the new ones, ensuring they are properly aligned and secure. After the repair, check the tool’s functionality to confirm the issue has been resolved.

Common Issues and Troubleshooting Tips

Even the best tools can experience occasional issues. Recognizing common problems and knowing how to troubleshoot them is essential for quick resolution. This section covers frequent malfunctions and offers practical advice on how to address them, ensuring that your tool runs efficiently and safely.

Here are some of the most common issues you may encounter:

- Engine Not Starting: This can be caused by a variety of factors, including a clogged air filter, faulty spark plug, or insufficient fuel.

- Weak or Uneven Cutting Performance: Issues like dull blades, improper tension, or a dirty fuel system can lead to poor cutting results.

- Excessive Vibration: Worn or loose parts, such as the handle or cutting mechanism, could result in more vibration than usual.

- Overheating: Overheating often happens due to poor airflow, a blocked exhaust, or dirty cooling fins.

For troubleshooting, consider the following tips:

- Check the Fuel System: Ensure the fuel is fresh and free of debris. Clean the fuel filter if necessary.

- Inspect the Spark Plug: If the engine isn’t starting or running rough, check for wear or damage on the spark plug and replace it if needed.

- Examine the Cutting Mechanism: Make sure the chain or blade is sharp and properly aligned. Also, check the tension and adjust it if required.

- Clean and Maintain Regularly: Regular cleaning of air filters, cooling fins, and other components can prevent many common issues from occurring.

By identifying the problem early and following these troubleshooting steps, you can often resolve the issue without the need for professional repair.