Maintaining and repairing outdoor power equipment can seem overwhelming, especially when dealing with complex mechanical systems. However, understanding how the different components work together is essential for efficient servicing. A detailed visual guide can help you quickly identify parts that need attention and ensure your tool operates smoothly for years to come.

Recognizing each part’s function and learning how to troubleshoot common issues is key to performing proper maintenance. Whether you’re replacing worn-out components or fixing malfunctioning ones, familiarity with the machine’s structure makes the process much more manageable.

In this article, we’ll provide a clear breakdown of key components and offer practical tips for maintenance. With this knowledge, you’ll be able to handle basic repairs on your own and maintain optimal performance throughout the lifespan of your equipment.

Understanding Stihl 026 Chainsaw Components

Properly maintaining your outdoor power tool requires a solid understanding of its individual components. Each piece serves a specific function, and knowing how they interact is essential for troubleshooting and repairs. A breakdown of these key elements ensures you can identify and replace faulty components when necessary, keeping your equipment running smoothly.

Engine and fuel system are at the core of any high-performance unit. They work together to provide the necessary power for cutting tasks. The fuel system consists of the fuel tank, carburetor, and fuel lines, each contributing to the efficient delivery of fuel to the engine. Any issue in this system can result in poor engine performance or failure to start.

Additionally, the ignition system is crucial for ensuring the spark that ignites the fuel. This system includes components like the spark plug and ignition coil. A malfunction here can cause starting issues or stalling during use. Regular checks of these systems are important to prevent disruptions during operation.

The drive and cutting mechanism is another vital area. The drive shaft, clutch, and sprocket work together to transfer power to the cutting chain. If any of these components are worn or damaged, it can affect the tool’s cutting efficiency. Proper inspection of the cutting mechanism is necessary to maintain precise performance during heavy-duty use.

How to Read a Chainsaw Parts Diagram

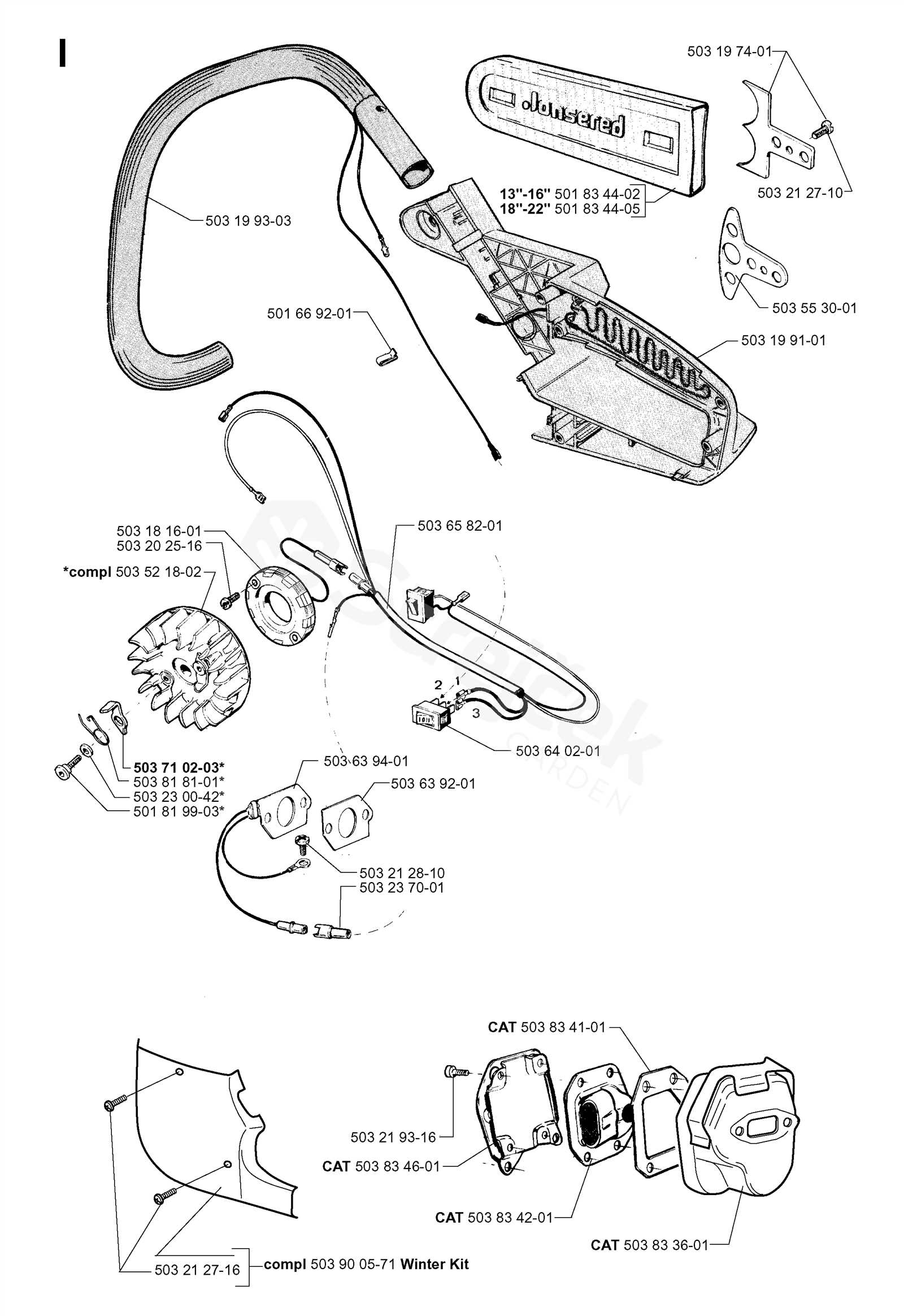

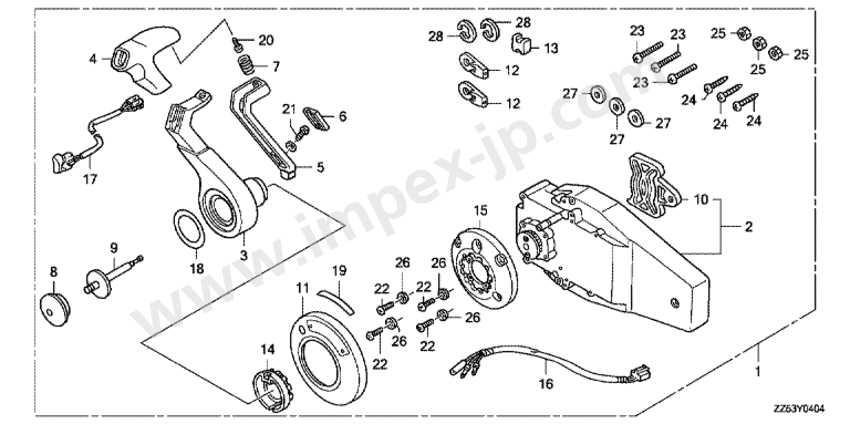

Understanding how to interpret a visual guide for mechanical tools is essential for any repair or maintenance task. These illustrations show the relationships between components, helping you pinpoint the exact part that needs attention. By carefully examining each section, you can identify the function of various pieces and understand how they work together within the tool.

Start by familiarizing yourself with the layout of the diagram. Typically, parts are organized in a logical order that reflects their position in the assembly. Most diagrams will label each component with a reference number or code. These references correspond to a detailed list of parts, often found in the tool’s manual or online resources.

Once you’ve identified a part in the diagram, check the accompanying reference guide for specific details such as part numbers and descriptions. This is particularly helpful when ordering replacements or understanding the specifications of each component. Pay attention to the orientation and connection points, as this will ensure proper reassembly and functioning.

Common Issues with Stihl 026 Parts

Even the most reliable outdoor tools can experience problems over time. Understanding common malfunctions is key to maintaining performance and preventing costly repairs. Many issues arise from wear and tear on critical components, while others can be caused by improper maintenance or lack of attention. Identifying and addressing these issues early can extend the lifespan of your equipment and improve its efficiency.

Engine and Fuel System Failures

One of the most frequent problems encountered is poor engine performance, often caused by issues within the fuel system. Clogged fuel lines, dirty filters, or a malfunctioning carburetor can disrupt fuel flow, leading to difficulty starting or stalling during operation. Regular cleaning and replacing fuel filters help prevent such issues and keep the engine running smoothly.

Drive Mechanism and Cutting Performance

Problems with the drive system, including the clutch or sprocket, can lead to reduced cutting power. A worn clutch or a loose chain can cause inefficient operation or even damage to the machine. Regular inspection and timely replacement of worn-out components ensure optimal cutting performance and prevent unexpected breakdowns during use.