When it comes to maintaining and repairing your equipment, knowing its internal structure is essential. Familiarity with each element can help you perform effective repairs and ensure long-lasting performance. This guide aims to provide a clear visual representation of the key components involved in chainsaw maintenance.

By understanding the placement and function of different parts, you can address issues more efficiently and make informed decisions when parts need replacing. Whether you’re a novice or an experienced user, mastering the component layout is crucial for optimal functionality.

Regular maintenance and precise repairs are vital to keeping your chainsaw in peak condition, extending its lifespan, and preventing common failures.

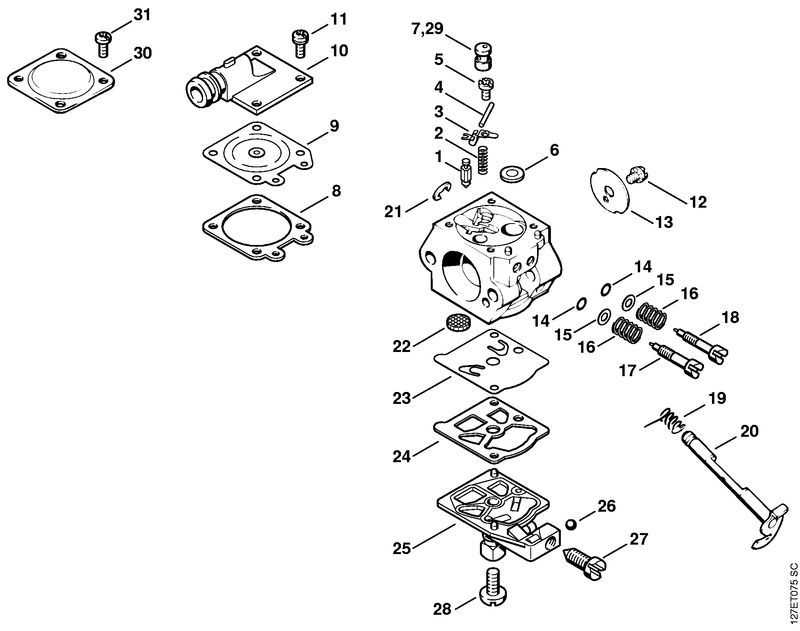

Understanding Chainsaw Component Layout

Familiarizing yourself with the internal configuration of your equipment is crucial for effective operation and maintenance. Recognizing where each element fits within the machinery allows you to diagnose problems and perform repairs with confidence. This section explores the structure of the tool and how each component interacts with the others for smooth performance.

Each section of the tool is designed to serve a specific function, from fuel delivery to engine power. By understanding the layout, you can easily identify the root cause of any issues and replace or fix parts with minimal effort. Whether you’re troubleshooting or performing routine maintenance, knowing the arrangement of the components is a key step in ensuring your equipment runs smoothly.

How to Read Chainsaw Component Layout

Interpreting the visual representation of your tool’s internal structure is essential for maintenance and repair tasks. A well-detailed schematic provides clear insights into the placement and connections of various elements. Understanding how to read this map allows you to identify parts quickly and make informed decisions during repairs or replacements.

Each section of the diagram is typically labeled with part numbers and corresponding functions. By studying the layout, you can trace the flow of operation, see how components connect, and detect any issues that may arise. Familiarity with the layout will help you navigate the repair process and ensure that each component is correctly assembled.

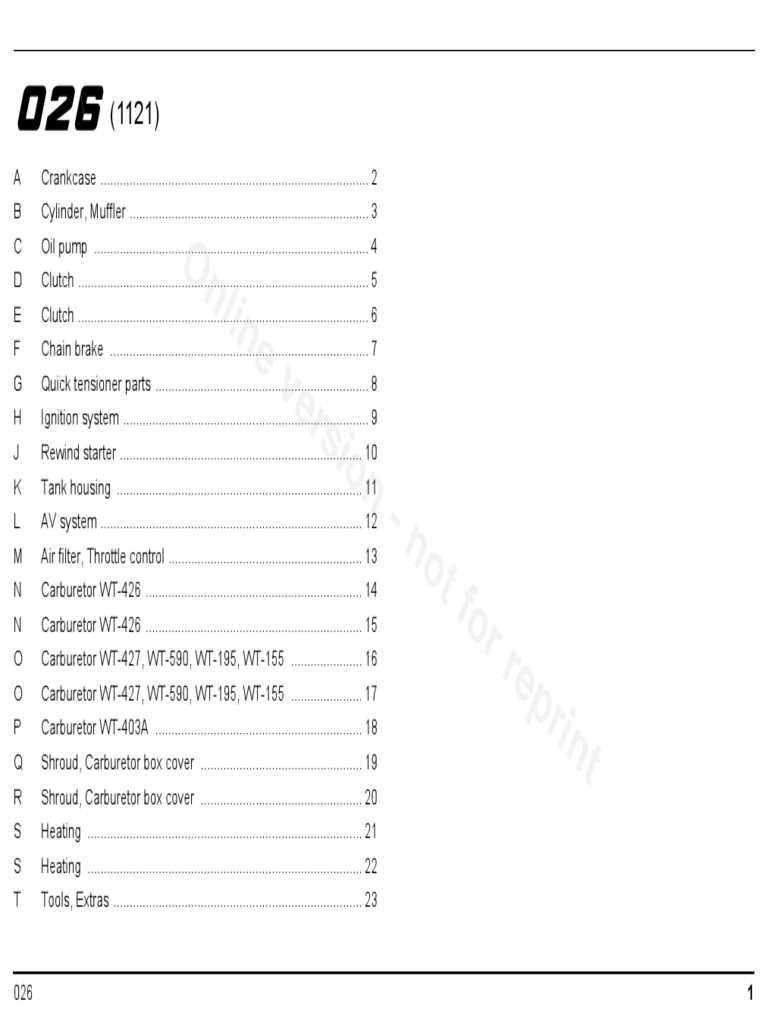

Common Chainsaw Components and Functions

Every tool has its own set of crucial elements that allow it to function properly. Understanding the common components and their roles is vital for anyone looking to maintain or repair the machine. From the engine to the cutting mechanism, each part contributes to the overall efficiency and performance of the equipment.

Engine and Fuel System

The engine is the heart of the tool, responsible for converting fuel into mechanical energy. The fuel system, including the carburetor and fuel lines, ensures that the engine receives the right amount of fuel for combustion. A well-maintained engine keeps the tool running smoothly and prevents unnecessary breakdowns.

Cutting Mechanism and Chain

The cutting system consists of the chain and bar, which work together to perform the primary function of the tool. The chain moves around the bar, cutting through material with precision. Regular inspection and tension adjustments ensure that the chain remains sharp and functional, allowing the tool to perform at its best.