For anyone working with chainsaws or similar equipment, understanding the internal structure and individual components is crucial. A clear visual representation of how the various pieces fit together can significantly aid in repairs, maintenance, and troubleshooting.

In this guide, we explore the essential parts and their organization within a specific model, offering a closer look at each element’s function. Whether you are performing routine maintenance or addressing a malfunction, knowing the correct assembly is vital for efficient and safe operation.

Knowing the layout of these crucial components is a valuable asset. It ensures that all pieces are correctly positioned and connected, ultimately improving the longevity and performance of the equipment. Having an accurate reference at hand helps both professionals and enthusiasts maintain their tools with ease and confidence.

Overview of Stihl 034 AV Components

Understanding the components of any machinery is essential for effective maintenance and repair. In this section, we will explore the main elements that make up the structure of a popular chainsaw model. Each piece plays a crucial role in the overall function and durability of the machine, ensuring it performs optimally over time.

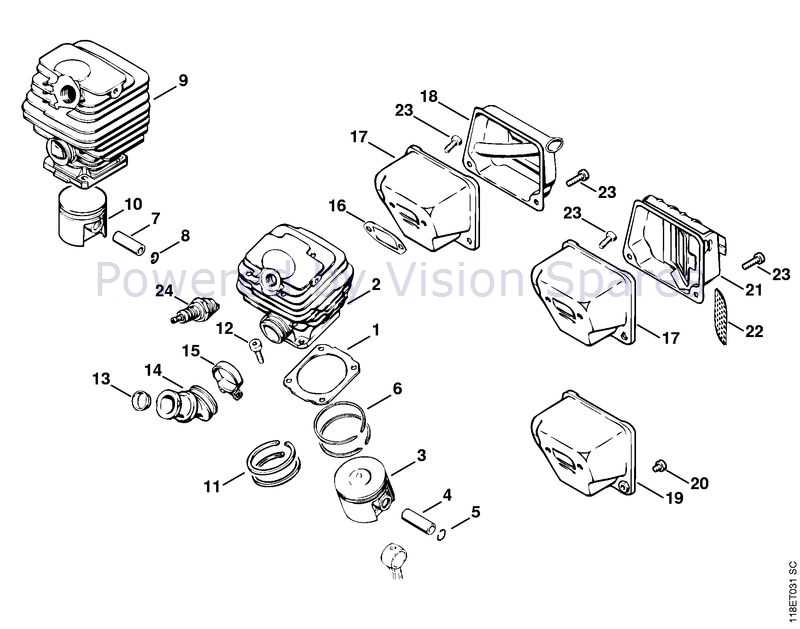

The engine system is at the heart of the equipment, consisting of several key elements that work in harmony to power the tool. Supporting this are the mechanisms that control the movement and stability of the saw, as well as those that help manage fuel flow and ignition.

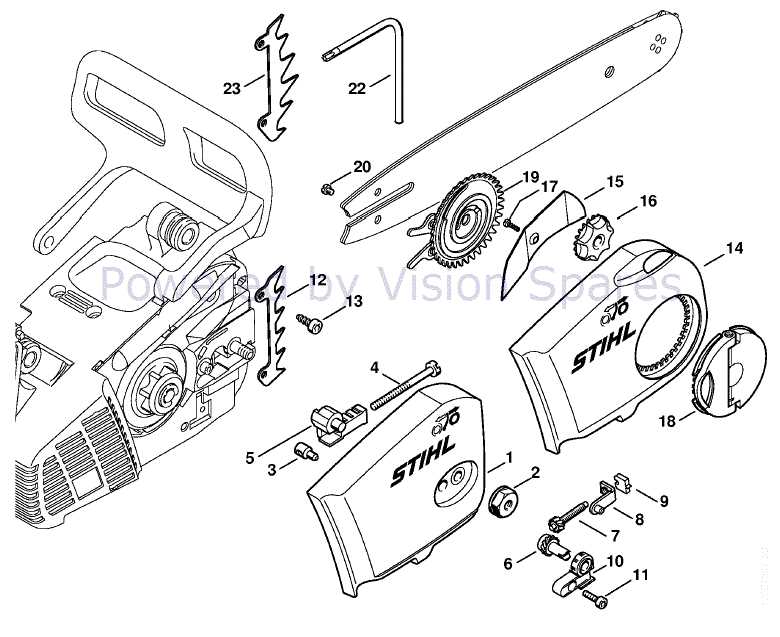

Other important components include safety features designed to protect the user and enhance operational control. These parts are designed with precision to ensure seamless performance and are built to withstand the stresses of regular use, offering longevity and reliability. Having a clear understanding of these elements allows for easier troubleshooting and maintenance, helping users keep their equipment in top condition.

Understanding the Parts Layout of Stihl 034 AV

Properly understanding the layout of a machine’s internal components is essential for anyone looking to maintain or repair it. A well-organized structure helps users identify each piece’s role and how they interact with others. In this section, we will explore how the components are arranged within a specific model, providing a comprehensive overview of their positioning and functionality.

Each part is strategically placed to optimize the performance of the equipment, with careful consideration given to how they connect and work together. From the central engine system to auxiliary components, the layout is designed for maximum efficiency and ease of maintenance. Knowing how each element fits within the overall structure ensures smoother repairs and reduces the likelihood of errors during reassembly.

By familiarizing yourself with the layout, you’ll be better equipped to troubleshoot issues and perform routine checks, ensuring your equipment remains in optimal working condition for extended periods. Understanding this arrangement also helps in identifying worn or damaged components that may need replacement, improving the tool’s overall lifespan.

How to Use the Diagram for Maintenance

Using a visual guide for maintenance tasks can greatly simplify the process of inspecting and repairing machinery. By referring to a clear schematic, users can easily identify components, their locations, and how they should be assembled. This visual tool serves as a reference point, helping ensure that each part is properly checked, installed, or replaced when needed.

When performing regular maintenance, begin by consulting the layout to pinpoint areas that require attention. The guide will provide a step-by-step overview, helping to identify which components may need lubrication, cleaning, or replacement. Following the diagram ensures that no part is overlooked and that each task is completed in the correct sequence.

Additionally, this tool can assist in troubleshooting by highlighting the connections between parts, allowing you to identify potential issues more efficiently. With a better understanding of how each element works together, you’ll be able to make informed decisions during the repair process, ultimately extending the life and functionality of your equipment.