Maintaining and repairing a chainsaw requires a clear understanding of its internal structure. A detailed visual representation of the tool’s components can be incredibly helpful for both beginners and experienced users. Knowing where each part fits and how they interact ensures smooth operation and effective repairs.

By studying a breakdown of the tool, users can identify specific areas that need attention or replacement. This guide offers an insightful look at the critical elements of the equipment, providing clear labels and explanations for each section. Being familiar with the layout of your tool can save time, reduce errors, and make regular maintenance tasks much easier to handle.

Whether you’re troubleshooting a malfunction or performing routine upkeep, understanding the design of your equipment can significantly improve the experience. Proper knowledge of its mechanics empowers you to keep your chainsaw running at peak performance for years to come.

Chainsaw Component Breakdown

Understanding the key components of a chainsaw is essential for ensuring its longevity and optimal performance. Each part plays a specific role in the operation, from the engine to the cutting mechanism. A clear breakdown of these components helps users identify areas that may need maintenance or replacement. Familiarity with the internal structure also allows for easier troubleshooting and quicker repairs.

Key Elements of the Mechanism

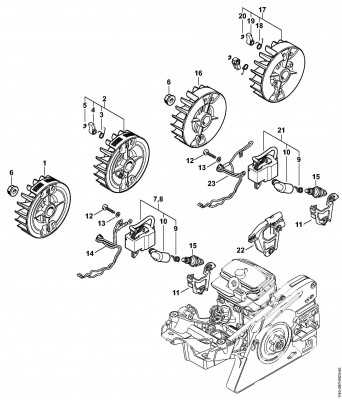

The heart of any chainsaw lies in its engine, which powers the entire system. Connected to the engine are various parts such as the ignition system, fuel delivery components, and the clutch assembly. These elements work together to convert fuel into energy, enabling the cutting chain to move efficiently. Ensuring these components are in good condition is crucial for maintaining smooth operation.

Cutting and Safety Features

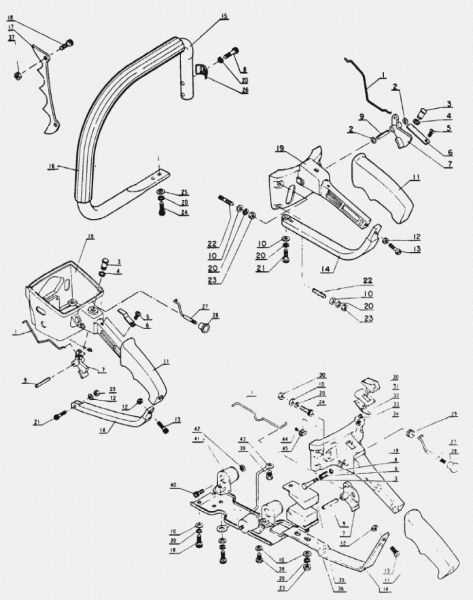

The cutting chain, guide bar, and tensioning system form the cutting mechanism. Proper maintenance of these parts ensures precise cuts and prolongs their lifespan. In addition, safety features like the brake and throttle lock contribute to the user’s protection while operating the tool. Keeping these systems functioning properly is vital for both performance and safety.

Understanding the Assembly of Your Chainsaw

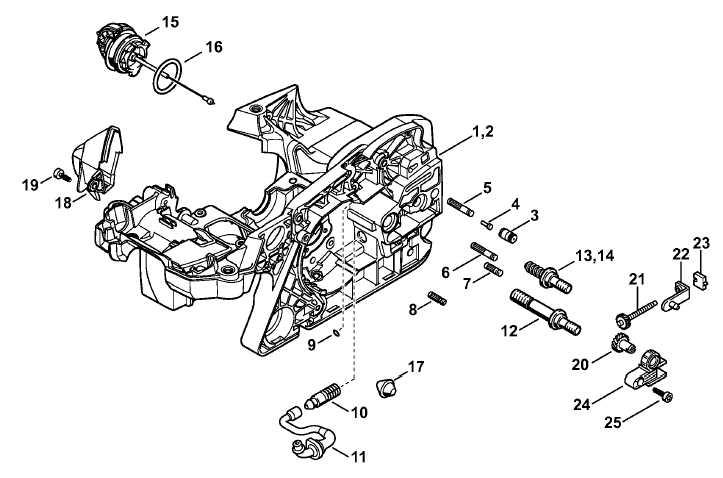

Knowing how the various components of your chainsaw fit together is crucial for proper usage and maintenance. Each section, from the motor to the cutting system, is interdependent, meaning any disruption in one area can affect the performance of the entire tool. A detailed understanding of the assembly process helps users reassemble the tool correctly after repairs and ensures that each component is functioning as intended.

The assembly starts with the engine, which serves as the core of the machine. Connected to it are the fuel system, air filter, and ignition system, all of which are essential for the chainsaw to start and run smoothly. Understanding how these parts work together is key to troubleshooting and ensuring the engine’s efficiency.

Attached to the engine are the drive components, which include the clutch, chain sprocket, and the guide bar. These elements transfer the engine’s power to the chain, allowing for precise cutting. The tensioning system that holds the cutting chain in place is also an important part of this assembly, helping maintain consistent performance during use.

How to Use the Chainsaw Assembly Guide

Using a comprehensive assembly guide is a valuable tool when performing repairs or maintenance on your chainsaw. It provides a clear visual representation of all the components and their arrangement, making it easier to identify parts that need attention. By referring to this guide, you can better understand how each section of the chainsaw fits together and how to reassemble it after disassembly.

To begin, locate the section relevant to the area you are working on. Each part will be numbered or labeled, allowing for easy identification. This visual reference helps to avoid confusion, ensuring that you install or replace the correct components in the right order. For example, if you’re troubleshooting the cutting mechanism, the guide will show how the chain, guide bar, and sprocket are positioned within the assembly.

Additionally, the guide can serve as a helpful resource when performing routine maintenance. By following the instructions step-by-step, you can ensure that the tool remains in optimal condition and that any worn or damaged parts are replaced properly. Whether you are a beginner or experienced user, this reference can simplify the process and improve the efficiency of repairs.